Allen Bradley 1753 Series GuardPLC 1800 Controller

Allen Bradley 1753 Series GuardPLC 1800 Controller

Core framework and scope of application of the document

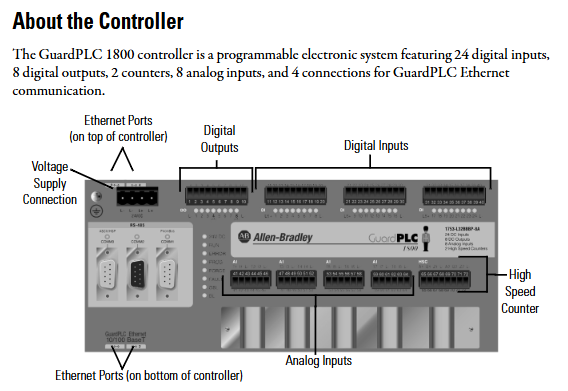

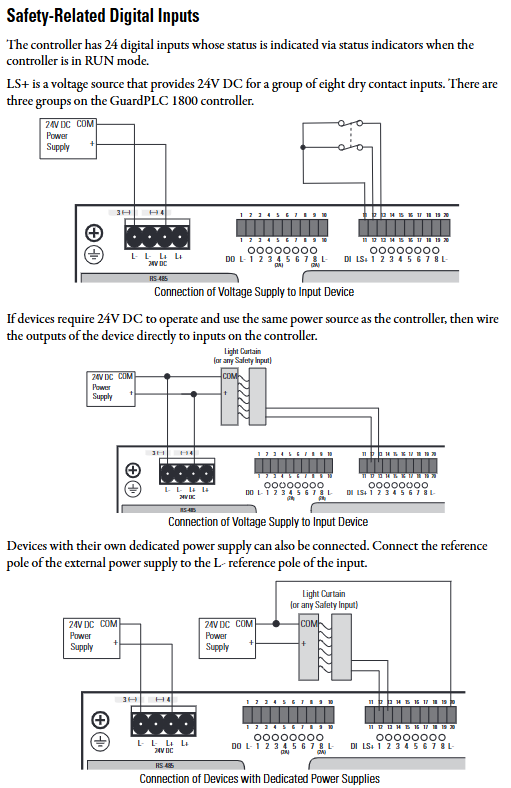

The document follows the logical mainline of "security standards → hardware awareness → installation and practical operation → functional verification", covering the entire process of controller preparation to later testing. The applicable product is GuardPLC 1800 safety controller, which is a programmable electronic system (PES) with safety certification. It integrates 24 digital inputs, 8 digital outputs, 2 high-speed counters, 8 analog inputs, and 4 GuardPLC Ethernet communication interfaces. It complies with SIL 3 (IEC 61508) and PLe (ISO 13849-1 Cat.4) safety levels and is suitable for scenarios with extremely high requirements for fault tolerance and risk control, such as mechanical safety control and process safety monitoring.

Core content sorting

(1) Controller Overview and Safety Standards

Core functions and hardware composition

Function integration: Supports the separation of secure and non secure communication. Secure communication is connected to distributed I/O, other GuardPLC controllers, or OPC servers through 4-channel 10/100BaseT RJ45 interfaces (GuardPLC Ethernet protocol); Non secure communication is achieved through 3-channel 9-pin D-shell interfaces (RS-485, etc.) to realize functions such as Modbus slave and Profibus DP slave (only 1753-L32BBBP-8A).

Hardware structure: including DIN rail installation buckle, 24V DC power interface, I/O plug-in terminal, high-speed counter interface, Ethernet interface (top 2+bottom 2), reset button (received design, anti misoperation), status indicator lights (24V DC, RUN, ERROR, PROMess, etc.). The controller is of open design and needs to be installed in a closed enclosure (protection level ≥ IP20).

Safety and Environmental Regulations

Operation qualification: It must be operated by trained professionals who are familiar with the application requirements of safety related PES (such as EN ISO 13849-1, IEC 61508).

Static electricity protection: The controller is sensitive to static electricity. When operating, it is necessary to touch a grounded object to discharge and wear a grounding wristband. It is forbidden to touch the pins or components of the circuit board. When idle, it should be stored in anti-static packaging.

Environmental requirements:

Working temperature: 0 ° C~60 ° C (32 ° F~140 ° F), storage temperature: -40 ° C~85 ° C (-40 ° F~185 ° F);

Relative humidity of 10%~95% (no condensation), pollution level 2 industrial environment, altitude ≤ 2000 meters (no need to downgrade);

It needs to be installed inside a metal casing with flame retardant properties (flame propagation level 5VA/V0, etc.), and the interior can only be accessed through tools to avoid the risk of electric shock.

(2) Installation process: from fixing to grounding

DIN rail installation (only supports DIN rail, not panel installation)

Align the guide rail: Hang the top slot of the controller on the IEC standard DIN rail (such as 199-DR1), and it is recommended to use galvanized yellow chromium steel material for the guide rail (to ensure good grounding). Fix it every 200mm (7.8 inches) and install end anchors.

Locking device: Insert a flathead screwdriver into the gap between the housing and the buckle, pull the buckle downwards, push the controller towards the guide rail, and release the buckle to complete the locking process; Reverse the operation during disassembly.

Heat dissipation requirements: Install horizontally with a minimum gap of 100mm (3.94 inches) above and below, avoiding installation above heating equipment to ensure air circulation. Install a fan if necessary.

Grounding configuration

Double grounding: The controller is functionally grounded through DIN rail, and protective grounding must be connected through a dedicated grounding screw (with grounding symbol) in the upper left corner of the housing. The grounding wire must comply with local electrical regulations (refer to Industrial Automation Wiring and Grounding Guidelines 1770-4.1).

Guide rail requirements: It is prohibited to use guide rails made of aluminum, plastic, or other materials that are prone to corrosion or have poor conductivity, in order to avoid equipment failure or safety risks caused by poor grounding.

(3) Wiring Specification: Power Supply and I/O Circuit

Power wiring (24V DC)

Power requirements: An isolated power supply that complies with EN 60950/UL 1950 must be used, and it must be of the SELV (Safety Extra Low Voltage) or PELV (Protection Extra Low Voltage) level. The SELV voltage should be ≤ 30V rms/42.4V peak/60V DC, and the PELV must be connected to a protective grounding.

Wiring details: Connect the power supply through a 4-pin terminal, and ensure that L+(positive pole) and L - (negative pole) are correctly connected (without reverse polarity protection, as reversing the connection may damage the controller); The terminal supports a maximum of 2.5mm ² (14 AWG) wire and requires external 10A delay fuse protection; The L+and L - terminals are internally connected, and 24V DC Daisy chain power can be supplied to other devices through the remaining terminals.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands