Understand the main production systems of underground mines

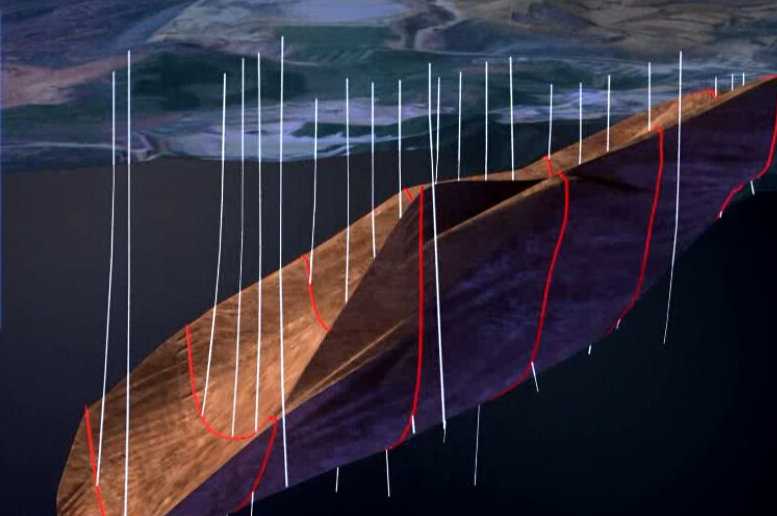

3) Inclined shaft lifting

Inclined shaft lifting has the advantages of fast construction and less investment. Its disadvantage is that the lifting speed is slow, especially when the diagonal length is large, the production capacity is small, the steel wire rope wear is large, and the shaft maintenance cost is high. Therefore, inclined shaft lifting is mostly used in small and medium-sized mines (except belt conveyor lifting).

Mining car group lifting is divided into single hook and double hook two kinds. The advantages of single hook truck group upgrading are that the required shaft section is small, less investment, low maintenance costs and easy to multi-level upgrading. The advantages of double hook mining car group upgrading are large output and small power consumption. The disadvantages are large shaft section, complex shaft loading and unloading yard, large investment, which is not conducive to multi-level upgrading. Generally, when the lifting of single hook truck group can meet the production requirements, the double hook truck group is not used for lifting.

Because of the large investment and long construction time, when the inclination of inclined shaft is less than 28°, the mining car group is used to lift the inclined shaft skip. However, the allowable speed of incline shaft skip lifting is larger and the stopping time is shorter, so in the mine with larger annual output, incline shaft skip lifting can be used regardless of the Angle. However, when the inclination is less than 18°, it can also be lifted by belt conveyor.

4) Recovery of powder ore

The shaft skip lifting is due to the ore spreading when loading and unloading ore, the ore spreading when misoperation, and the ore containing water and mud or the underground mine silo rock seepage, the powder ore or mud and water mixed into the bottom of the well through the gate gap, forming a large amount of pulp, resulting in the accumulation of powder ore at the bottom of the well. In addition to taking effective measures to reduce the source of fine ore, it is necessary to design a recovery device for fine ore. There are several general recovery methods for fine ore.

(1) The bottom of the mine is used as a powder mine bin, starting from the lowest discharge level of the shaft, a small cage shaft (or small skip inclined shaft) is dug down, and the roadway is connected with the loading port of the powder mine bin at the bottom of the skip mine. After the powder mine is loaded by the funnel gate, the small cage (or small skip inclined shaft) is lifted and unloaded into the skip mine bin.

(2) When the mixed well lifting is used, the powder ore bin is located on the bottom side of the well, the bottom cage enters and exits the truck, and is connected to the loading port of the powder ore bin by a side channel. After the powder ore is loaded into the truck, the powder ore is lifted by the cage and unloaded into the skip ore bin or directly raised to the surface.

(3) When the main shaft and auxiliary shaft are near, the auxiliary shaft is one level ahead of the main shaft, and the powder ore is loaded by the powder ore bin at the bottom of the main shaft, and then lifted and unloaded into the skip ore bin by the auxiliary shaft, or directly raised to the surface.

Among the above three methods, method (1) has the largest amount of development engineering and is inconvenient to manage, but it can avoid the shortcomings of the last two methods when the balance tail rope or rope can rope passes through the powder ore bin.

(2) Underground transportation

1. Classification of underground transportation

Underground transportation is an important link in the mining and production of underground metallic and non-metallic mines, and its work scope includes stope transportation and roadway transportation. It is the transport channel of continuous stope, driving face and underground ore bin, filling goaf or surface ore bin and waste rock yard. Stope transport includes gravity self-sliding transport, electric rake transport, trackless self-propelled equipment transport (scraper, loader or mining vehicle), vibration mining machine transport and explosive force transport. Roadway transportation includes the transportation of stage roadway and inclined roadway, that is, the roadway transportation between the stope funnel, stope raise or pass below the underground ore storage bin (or tunnel mouth).

2. Underground transportation system

Underground mine transportation system and transportation mode are generally determined in the design of ore deposit development. The principle of determination should consider the occurrence conditions of the deposit, development system, mining method, mining scale, production service life, the development status of transportation equipment and the management level of the enterprise. It should be technologically advanced and reliable, economically reasonable and favorable, safe operation, convenient management, low energy consumption and less investment.

1) Rail transport

Rail transportation generally refers to locomotive transportation, which is the main transportation mode of underground mines at home and abroad. Rail transportation is mainly composed of mining cars, traction equipment and auxiliary machinery and other equipment, often with raking, loading, belt conveyor or trackless transportation equipment to form an effective transportation system, in the production process can transport ore, waste rock, materials, equipment and personnel. It is one of the main factors that organize production and determine mine production capacity.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands