Understand the main production systems of underground mines

Lift transport

(1) Mine lifting

Mine lifting is the transportation link of transporting ore, waste rock and lifting personnel, materials and equipment along the shaft with certain equipment. According to the way to lift materials can be divided into two categories, one is rope lifting (wire rope lifting), the other is cordless lifting (such as belt conveyor lifting, hydraulic lifting and pneumatic lifting, etc.), of which wire rope lifting is more widely used.

1. Composition of mine lifting equipment

The main components of mine lifting equipment are lifting container, lifting wire rope, lifting machine (including drag device), derrick and sky wheel and loading and unloading and other auxiliary devices.

2. Classification of mine lifting equipment

(1) According to the inclination of the shaft, it is divided into vertical shaft lifting equipment and inclined shaft lifting equipment.

(2) According to the type of lifting container, it is divided into cage lifting equipment, skip lifting equipment, skip - cage lifting equipment, sinking bucket lifting equipment, incline shaft and string car lifting equipment.

(3) According to the purpose of upgrading, it is divided into main lifting equipment (specialized or mainly lifting ore, generally known as the main shaft lifting equipment), auxiliary lifting equipment (lifting waste rock, lifting personnel, transporting materials and equipment, etc., generally known as auxiliary shaft lifting equipment) and auxiliary lifting equipment (such as patio elevators, maintenance and upgrading, etc.).

(4) According to the type of elevator, it is divided into single-rope winding lifting equipment (it has a single drum and a double drum), multi-rope winding lifting equipment, single-rope friction lifting equipment (no longer produced), multi-rope friction lifting equipment.

(5) According to the number of lifting containers, it is divided into single container lifting equipment (with balance hammer) and double container lifting equipment.

(6) According to the balance state of the lifting system, it is divided into unbalanced lifting equipment and static balance lifting equipment.

(7) According to the drag type is divided into AC lifting equipment, DC lifting equipment.

3. Upgrade the system

1) Shaft single rope winding lifting

For the mine with a depth of less than 300m and a drum diameter of less than 3m, it is appropriate to use a single rope winding lifting system. The selection of cage or skip as the lifting container is an important issue in the design, which needs to be determined by comparison in all aspects (the same with multi-rope friction lifting).

Usually, when designing the lifting system, two sets of lifting equipment, main and auxiliary, are used to ensure the mine output and complete other lifting tasks. The main shaft uses skip to lift ore, and the auxiliary shaft uses cage to complete the auxiliary lifting task, or the main and auxiliary shafts all use cage. Which method to adopt should be determined according to the specific conditions of each mine. When the annual output of the mine is large, it is best to use the way of the main shaft skip and auxiliary shaft cage. When the annual output of the mine is small or more than two kinds of ore, or the ore is not suitable for crushing, it is best to use the cage.

When multi-level lifting, usually in the production is not very large but the lifting level of the mine using a balanced hammer single cage lifting, sometimes in order to ensure the production with two sets of balanced hammer single cage lifting.

For mines with small annual output, a set of cage lifting equipment can be used to complete all lifting tasks. This is true of many non-ferrous metal mines, non-metallic mines and nuclear industrial mines in China.

2) Shaft multi-rope friction lifting

Multi-rope friction elevator has many advantages, therefore, in addition to the use of multi-rope friction elevator instead of a single rope winding elevator with a drum diameter greater than 3m when the well depth is greater than 300m, you can also use a smaller multi-rope friction elevator instead of a single rope winding elevator with a drum diameter of less than 3m.

Because multi-rope friction lifting is difficult to adjust the length of the rope, the double container lifting is only suitable for one production level. At the same time, due to the influence of the deformation of the lifting wire rope, the double container lifting system can only ensure the accurate stopping of the wellhead in the actual operation, but can not ensure that the container at the bottom of the well is stopped in the exact position (for the skip lifting, the accuracy of the stopping is not strict).

The single-vessel balancing hammer lifting system is especially suitable for mines with multiple levels of lifting. And the balance hammer lifting can improve the anti-slip performance of the multi-rope friction lifting system. Moreover, because the single-container lifting system is not affected by the deformation of the wire rope, it can ensure accurate stopping at all production levels, so it is used more. For more than two kinds of ore types of multi-level lifting, according to the specific production and production level needs, in a shaft installed two sets of single container lifting equipment can also be used a single container, a set of double container lifting system.

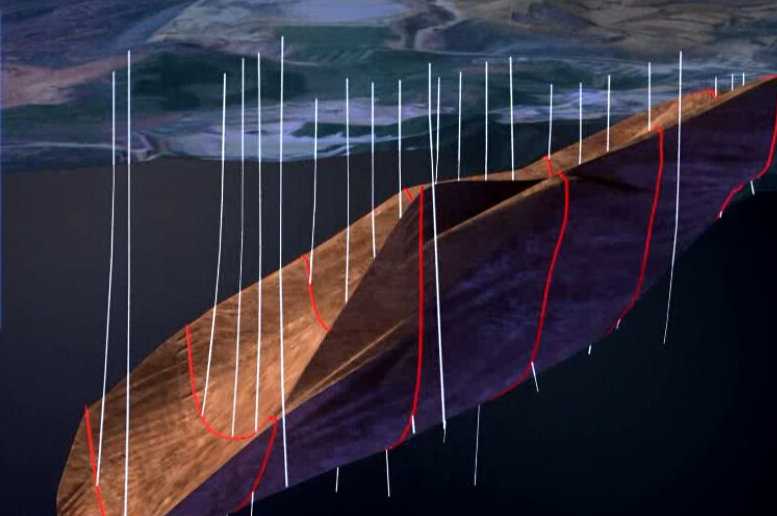

3) Inclined shaft lifting

Inclined shaft lifting has the advantages of fast construction and less investment. Its disadvantage is that the lifting speed is slow, especially when the diagonal length is large, the production capacity is small, the steel wire rope wear is large, and the shaft maintenance cost is high. Therefore, inclined shaft lifting is mostly used in small and medium-sized mines (except belt conveyor lifting).

Mining car group lifting is divided into single hook and double hook two kinds. The advantages of single hook truck group upgrading are that the required shaft section is small, less investment, low maintenance costs and easy to multi-level upgrading. The advantages of double hook mining car group upgrading are large output and small power consumption. The disadvantages are large shaft section, complex shaft loading and unloading yard, large investment, which is not conducive to multi-level upgrading. Generally, when the lifting of single hook truck group can meet the production requirements, the double hook truck group is not used for lifting.

Because of the large investment and long construction time, when the inclination of inclined shaft is less than 28°, the mining car group is used to lift the inclined shaft skip. However, the allowable speed of incline shaft skip lifting is larger and the stopping time is shorter, so in the mine with larger annual output, incline shaft skip lifting can be used regardless of the Angle. However, when the inclination is less than 18°, it can also be lifted by belt conveyor.

4) Recovery of powder ore

The shaft skip lifting is due to the ore spreading when loading and unloading ore, the ore spreading when misoperation, and the ore containing water and mud or the underground mine silo rock seepage, the powder ore or mud and water mixed into the bottom of the well through the gate gap, forming a large amount of pulp, resulting in the accumulation of powder ore at the bottom of the well. In addition to taking effective measures to reduce the source of fine ore, it is necessary to design a recovery device for fine ore. There are several general recovery methods for fine ore.

(1) The bottom of the mine is used as a powder mine bin, starting from the lowest discharge level of the shaft, a small cage shaft (or small skip inclined shaft) is dug down, and the roadway is connected with the loading port of the powder mine bin at the bottom of the skip mine. After the powder mine is loaded by the funnel gate, the small cage (or small skip inclined shaft) is lifted and unloaded into the skip mine bin.

(2) When the mixed well lifting is used, the powder ore bin is located on the bottom side of the well, the bottom cage enters and exits the truck, and is connected to the loading port of the powder ore bin by a side channel. After the powder ore is loaded into the truck, the powder ore is lifted by the cage and unloaded into the skip ore bin or directly raised to the surface.

(3) When the main shaft and auxiliary shaft are near, the auxiliary shaft is one level ahead of the main shaft, and the powder ore is loaded by the powder ore bin at the bottom of the main shaft, and then lifted and unloaded into the skip ore bin by the auxiliary shaft, or directly raised to the surface.

Among the above three methods, method (1) has the largest amount of development engineering and is inconvenient to manage, but it can avoid the shortcomings of the last two methods when the balance tail rope or rope can rope passes through the powder ore bin.

(2) Underground transportation

1. Classification of underground transportation

Underground transportation is an important link in the mining and production of underground metallic and non-metallic mines, and its work scope includes stope transportation and roadway transportation. It is the transport channel of continuous stope, driving face and underground ore bin, filling goaf or surface ore bin and waste rock yard. Stope transport includes gravity self-sliding transport, electric rake transport, trackless self-propelled equipment transport (scraper, loader or mining vehicle), vibration mining machine transport and explosive force transport. Roadway transportation includes the transportation of stage roadway and inclined roadway, that is, the roadway transportation between the stope funnel, stope raise or pass below the underground ore storage bin (or tunnel mouth).

2. Underground transportation system

Underground mine transportation system and transportation mode are generally determined in the design of ore deposit development. The principle of determination should consider the occurrence conditions of the deposit, development system, mining method, mining scale, production service life, the development status of transportation equipment and the management level of the enterprise. It should be technologically advanced and reliable, economically reasonable and favorable, safe operation, convenient management, low energy consumption and less investment.

1) Rail transport

Rail transportation generally refers to locomotive transportation, which is the main transportation mode of underground mines at home and abroad. Rail transportation is mainly composed of mining cars, traction equipment and auxiliary machinery and other equipment, often with raking, loading, belt conveyor or trackless transportation equipment to form an effective transportation system, in the production process can transport ore, waste rock, materials, equipment and personnel. It is one of the main factors that organize production and determine mine production capacity.

The advantages of rail transportation are wide use, large production (determined by the number of locomotives), unrestricted transport distance, good economy, flexible scheduling, and can transport a variety of ores along the bifurcation line. The disadvantage is that the transportation is intermittent, the production efficiency depends on the level of work organization and the applicable roadway slope has limitations (generally 3‰~5‰), and it is difficult to ensure transportation safety when the slope of the line is too large.

The locomotive-drawn mine car train running on the track is the main mode of horizontal long-distance transportation. The track gauge is divided into standard gauge and narrow gauge, the standard gauge is 1435mm, and the narrow gauge is divided into 600mm, 762mm and 900mm. According to the different gauge, the locomotive can also be divided into standard gauge locomotive and narrow gauge locomotive; According to the different power used, mining locomotives can be divided into electric locomotives, internal combustion locomotives and steam locomotives. Steam locomotives have been largely phased out, and internal combustion locomotives are generally used only on the surface. Electric locomotive is driven by electric energy, according to the nature of the power supply is different, electric locomotive can be divided into direct current locomotive and alternating current locomotive, direct current locomotive is the most widely used. Now, many users have begun to use variable frequency electric locomotives. According to different power supply methods, DC locomotives are divided into trolley type electric locomotives and battery electric locomotives, and most of the non-coal mine in China are trolley type electric locomotives.

The trolley type electric locomotive has the advantages of simple structure, low cost, convenient maintenance, large transportation capacity, high speed, high power efficiency, low transportation cost, and is widely used. Its disadvantage is that it must have rectification and wiring facilities, which is not flexible enough; The wiring has a certain impact on the size of the roadway and the safety of pedestrians. It is easy to generate sparks between the collector and the wiring, and it is not allowed to invest more in the initial construction of the mine with serious gas, but in the long run, the total cost of using the wiring electric locomotive is much lower than that of the battery electric locomotive. There are two kinds of DC voltage of domestic underground wiring grid: 250V and 550V.

Accumulator electric locomotives are powered by batteries. The battery is usually charged in the underground motor garage. After the battery pack on the motor car is used to a certain extent, it can be replaced with a well-charged battery. The advantage of this electric locomotive is that there is no spark detonating danger, suitable for use in the mine with gas without wire, flexible use, for small output, roadway is not too regular transportation system and roadway excavation transportation is very suitable. The disadvantage is that the initial investment in charging equipment is low, and the transportation cost is high. Generally, the trolley type electric locomotive is used in the mining stage, and the battery electric locomotive can be used in the development stage to overcome the external conditions. In the return air roadway with explosive gas, cable electric locomotive should not be used, and in the mine with high sulfur and risk of spontaneous ignition, explosion-proof battery electric locomotive should be used.

In addition to the above two kinds of electric locomotives, there are compound energy electric locomotives, which can be mainly divided into wire - battery electric locomotive and wire - cable electric locomotive. There is an automatic charger on the trolley, and the trolley power supply can be used to automatically charge the car battery at any time, and there is no need to charge the charging room often, which can improve the utilization rate of the locomotive; It can also be directly driven into the development roadway, the use of flexible; When the cable-type electric locomotive is working in the main transportation lane, it obtains electric energy directly from the cable-type electric locomotive. When driving in the area where it is inconvenient to install cable, it can be powered by cable, but the transport distance of cable power supply cannot exceed the length of cable.

Diesel locomotives do not need wiring, low investment, very flexible. However, the structure is complicated and the exhaust gas pollutes the air, so it is necessary to install the exhaust gas purification device in the exhaust port and strengthen the ventilation of the roadway. At present, this kind of locomotive is only used in a few mines in the surface joint section and surface transportation of well-ventilated tunnels in China, and it is used more in foreign mines.

There are mining vehicles for transporting ore (waste rock), transporting personnel vehicles, material vehicles, explosive vehicles, water trucks, fire trucks and health vehicles.

2) Trackless transport

The use of trackless self-propelled equipment transportation in underground mines began in the 1960s. With the improvement of underground trackless equipment, underground trackless mining technology has also been rapidly developed.

Underground mine car is a self-propelled vehicle specially designed for underground mine, is the main transport vehicle to realize trackless mining technology, has the advantages of mobility, flexibility, versatility and economy. Underground mining vehicles are widely used in all kinds of underground mines with suitable conditions for intensive mining, which can not only improve the labor productivity and output of underground mines, promote the continuous expansion of production scale, but also change the mining technology, mining method and excavation transportation system of such mines. Especially with the development of mining automation, intelligent mining and other technologies and systems in recent years, underground mines are moving towards the unmanned direction of trackless mining.

(1) The main advantages of underground mine motor transport are

① Flexible, wide range of application, large production potential. The mining face can be directly transported to each unloading site without intermediate transfer, and the unloading site is not restricted. Personnel, materials, and equipment can also be directly reached the working face without transfer.

Under certain conditions, the use of underground mining truck transport can properly save equipment, steel and personnel.

(3) Before the completion of the full set of shaft facilities, it is possible to advance the mine and facilitate the mining and transportation of marginal and sporadic orebodies.

(4) Under the condition of reasonable transport distance, there are fewer production links of underground mine automobile transport, which can significantly improve labor productivity.

(2) The disadvantages of underground mine motor transport are:

Although underground mining vehicles have exhaust gas purification devices, the exhaust gas emitted by diesel engines pollutes the underground air, which can not be completely solved at present. Measures such as strengthening ventilation are usually adopted, which increases the cost of ventilation equipment.

Due to the poor quality of the underground mine road surface, tire consumption is large, and the cost of spare parts is increased.

The maintenance workload is large, requiring skilled maintenance workers and well-equipped maintenance workshops.

(4) In order to facilitate the driving of underground mining vehicles, the required roadway section size is larger, increasing the development cost.

(3) Compared with ground dump vehicles, underground mining vehicles usually have the following characteristics in structure:

① Can be disassembled, convenient for large pieces down the well.

② Articulated chassis, hydraulic steering, narrow body width, small turning radius.

The car body height is low, generally 2~3m, suitable for operation in narrow and low underground space, low center of gravity, increasing the climbing ability.

④ The driving speed is low, and the engine power is smaller, thus reducing the exhaust emissions.

3) Belt conveyor transport

Belt conveyor transport is a continuous mode of transport, mainly used to transport minerals and rocks, but also to transport materials and personnel. This mode of transportation has large production capacity, safety and reliability, simple operation and high degree of automation. With the use of high-strength tape, belt conveyor transportation has the characteristics of long distance, large volume and high speed, which meets the requirements of efficient transportation of modern mining equipment.

The use of belt conveyor transportation in underground mines is limited by the degree of rock mass, the volume of traffic, the inclination of roadway, bends and so on. Usually, it can only transport the ore and rock that has been coarse crushed (the block is less than 350mm), and it is only suitable for use in the case of large volume, small inclination of roadway, and no bend.

Underground belt conveyor transport according to its use place and completed transportation tasks can be divided into: ① stope belt conveyor transport, it directly from the mining face to accept and transport minerals and rocks. (2) Ore collection belt conveyor transport, which receives ore from two or more belt conveyors. (3) Trunk belt conveyor transport, which transports all the ore and rock mined underground, including the belt conveyor transport through the roadway and inclined shaft to the surface.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands