Watlow Anafaze System 32 Hardware Installation Guide

Watlow Anafaze System 32: Legacy Engineering and Hardware Implementation

The Definitive Guide to PIOM Modules, Analog Interfacing, and Signal Integrity

1. Introduction to the System 32 Ecosystem

The Watlow Anafaze System 32, introduced in the late 1980s, remains a cornerstone of legacy industrial process control. Designed as a high-density measurement and control system, it provided a modular approach to multi-loop PID control that was ahead of its time. At the heart of this system lies the Processor I/O Module (PIOM), which coordinates the data flow between analog inputs and control outputs.

2. Processor I/O Module (PIOM) Fundamentals

The PIOM acts as the central nervous system of the System 32. It handles all computational tasks for the control loops and manages communication with the host computer. Understanding its physical interface is crucial for hardware technicians.

Input Control and Watchdog Timer

A critical feature of the PIOM is the Communications Watchdog Timer. This safety mechanism ensures that if communication with the host computer is lost, the controller can default to a safe state. As noted in the troubleshooting section, if the watchdog is enabled, control outputs may be set to 0% if the host fails to "pet" the timer periodically.

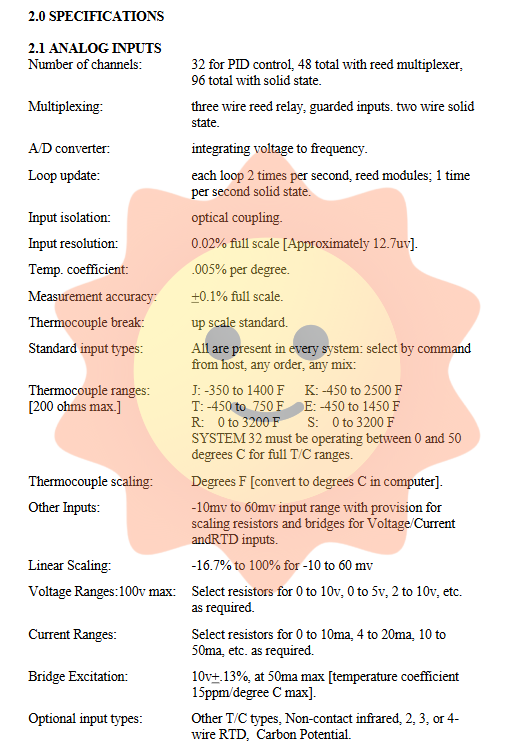

3. Analog Input Boards: RRAIM and SSAIM Specifications

Precision measurement is achieved through specialized analog input modules. The System 32 typically utilizes Remote Resistance Analog Input Modules (RRAIM) or Solid State Analog Input Modules (SSAIM).

| Module Component | Functional Description |

|---|---|

| Isolated Supply (Green LED) | Indicates the internal isolated power is active and stable. |

| Scan Indicator (Orange LED) | Flashing indicates the input module is actively scanning sensors. |

| Cold Junction Compensation | Integrated thermistor for accurate thermocouple referencing. |

| Terminal Block (TB2) | Primary interface for digital I/O and communication links. |

Signal integrity is maintained through galvanic isolation. The manual emphasizes that measured data errors (Section 11.4.6) are often linked to the input module's scanning state. A solid green light and a flashing orange light are the "gold standard" for a healthy analog subsystem.

4. Digital I/O and Control Output Enabling

In the System 32 architecture, the enabling of control outputs is not purely software-driven; it requires a physical hardware interlock. This is a vital safety feature for industrial heating and process applications.

Without this physical jumper or an external logic signal, the Anasoft operating program may display output values (e.g., 50%), but the actual physical output terminals will remain at 0 volts. This "Hardware Enable" logic prevents accidental activation during maintenance or system boot-up.

5. Serial Communication Protocols: RS-232 and RS-422

The System 32 was designed for networked environments long before the ubiquity of Ethernet in factories. It supports both point-to-point and multi-drop communication standards.

RS-232 Interface: Used for short-distance connection (up to 50 feet) directly to a PC COM port.

RS-422 Interface: Preferred for industrial environments, allowing for cable runs up to 4,000 feet and high noise immunity through differential signaling.

Proper shielding and the use of twisted-pair wiring are emphasized in the manual to prevent data corruption in high-EMI environments, such as those near high-power motors or heaters.

6. Diagnostics and Troubleshooting Methodologies

The Revision 5 manual provides a systematic approach to fault isolation. The hierarchy of troubleshooting begins with power verification and proceeds through communication and finally to the I/O modules.

Common Symptom: No Control Outputs

If the PIOM is healthy but no outputs are present, the manual suggests checking the Watchdog Timer (Section 3.3.2) and the physical OUTPUTS ON jumper. If these are correct, the fault likely lies within the Processor I/O Module’s digital output drivers.

7. Conclusion: The Enduring Engineering of System 32

Despite being a product of the 1980s, the Watlow Anafaze System 32 represents a robust example of deterministic industrial control. Its modular hardware design, combined with clear diagnostic indicators and hardware-level safety interlocks, ensures that many of these units remain in operation today. For engineers maintaining these systems, the key to success lies in understanding the interplay between the PIOM logic and the physical terminal connections.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands