Watlow 8LS Controller Setup Guide

Watlow 8LS PID Controller Installation, Programming, and Operation Professional Guide

The Watlow Anafaze 8LS controller is a powerful 1/4 DIN size industrial grade controller designed specifically for complex process control. It provides 8 completely independent PID (Proportional Integral Derivative) control loops, which can directly connect various industrial sensors, including thermocouples (T/C), thermistors (RTD), and infrared non-contact sensors. This guide will provide a detailed overview of the technical specifications, mechanical installation, electrical wiring, programming settings, PID tuning, and troubleshooting methods of the 8LS controller, helping engineers and technicians quickly master the deployment and application of the equipment.

1. Hardware Overview and Core Features

The design of the 8LS controller aims to meet various needs from simple switch control to complex PID regulation. It can operate as an independent controller or be integrated into a computer monitoring system through RS-232 or RS-485 serial interfaces. Its core features include:

Multi loop control: Provides 8 independent PID control loops, each with dual outputs for heating and cooling, suitable for heating/cooling applications.

Flexible sensor input: Supports direct connection to J, K, T, E, N-type thermocouples, as well as RTD and linear voltage/current inputs (with scaling resistors required).

Powerful output capability: The main and secondary outputs of each circuit can be independently configured as time proportional (TP), zero crossing detection (DZC), switch (ON/OFF), or analog output (0-5VDC or 4-20mA).

Comprehensive alarm function: including deviation alarm, high/low process alarm, and global alarm output, which can accurately set dead zone and delay according to process requirements.

Optional advanced features: support for built-in Ramp/Soak programmer for batch processing, and 8LS-CP (carbon potential) function for carbon potential control and furnace gas monitoring.

2. Installation and mechanical requirements

When installing the 8LS controller, it is necessary to strictly comply with safety and regulatory requirements to ensure the reliable operation and long-term stability of the equipment.

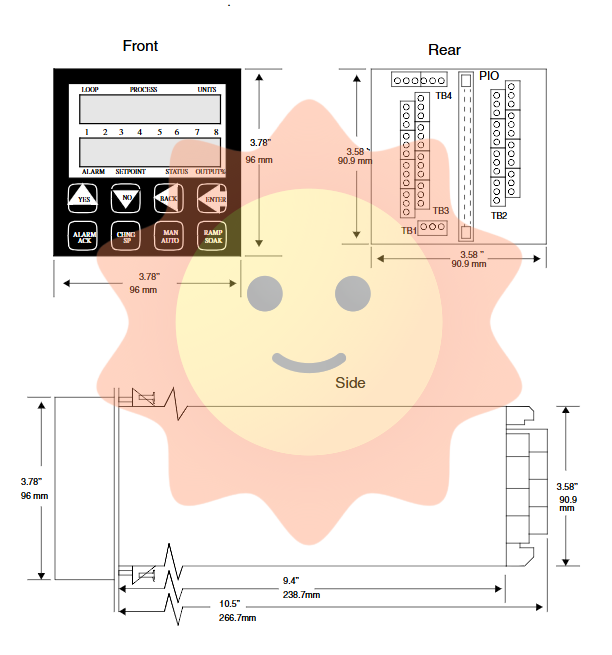

Mechanical installation: The 8LS adopts a 1/4 DIN housing design, with standard panel opening dimensions of 92mm x 92mm (height x width). The equipment should be installed vertically on a metal backplate to ensure heat dissipation. In order to ensure the highest accuracy of thermocouple input, the temperature gradient on the housing terminal block should be minimized as much as possible to prevent thermal shock.

Heat dissipation and environment: Ensure sufficient airflow through the housing slot at rated full current output. During installation, avoid being obstructed by other heat sources and ensure that the surrounding environment temperature meets the specifications.

Electrical safety: The power must be cut off before installation. Due to the fact that the input signal of 8LS is not always referenced to ground, there may still be high voltage on the signal line in an unpowered state (such as a thermocouple accidentally short circuiting to the AC power line). After installation, the controller must be placed inside a protective enclosure to prevent operators from coming into contact with live parts.

3. Wiring and electrical specifications

Correct wiring is the key to ensuring measurement accuracy and control stability. The following are detailed wiring requirements and measures to suppress interference.

Analog input wiring:

Thermocouple: Special thermocouple extension wires must be used and routed in their own conduits, away from AC power sources and high-power lines.

RTD: It is recommended to use a three wire RTD (100 Ω platinum resistor) and a multi-core shielded cable.

Linear input: Shielded twisted pair or multi-core shielded cable should be used. For voltage or current input, a scaling resistor must be installed on the 8LS terminal to match the input range of -10mV to+60mV.

Grounding and shielding: The shielding layer of analog signals is usually only grounded on the controller side (120VAC panel ground) or on the sensor side depending on the site conditions. The analog signal ground should be connected to the Analog GND terminal and strictly separated from the logic ground and communication ground.

Control output wiring:

The PID digital output of 8LS adopts optical isolation solid-state relay technology. The radio frequency interference (RFI) generated instantly by the switch when driving the electromechanical relay may cause CPU reset or display failure.

Anti interference measures:

Try to use solid-state relay (SSR) instead of electromechanical relay as much as possible.

Mechanical and electrical relays should not be installed on the same panel as 8LS as much as possible.

Strictly control the circuit and avoid bundling digital output lines with AC power lines.

RC buffer network: This is the most important measure to suppress RFI. Connect a 0.01uF/1000VDC capacitor and a 47 Ω/0.5W resistor in parallel to the normally open (NO) contact of the electromechanical relay coil.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor