Watlow ANAFAZE 12LS Installation and Operation Technical Guide

Technical Analysis: ANAFAZE 12LS Multi-Loop Controller

Legacy Precision in Modern Thermal Process Management

1. Executive Summary: The Legacy of ANAFAZE 12LS

The ANAFAZE 12LS stands as a landmark in the evolution of multi-loop process control. Originally developed by Anafaze Incorporated (later becoming part of Watlow), this system was designed to provide robust, high-density control solutions for complex industrial applications. Its ability to manage multiple independent control loops within a single compact unit revolutionized thermal management in the early 1990s.

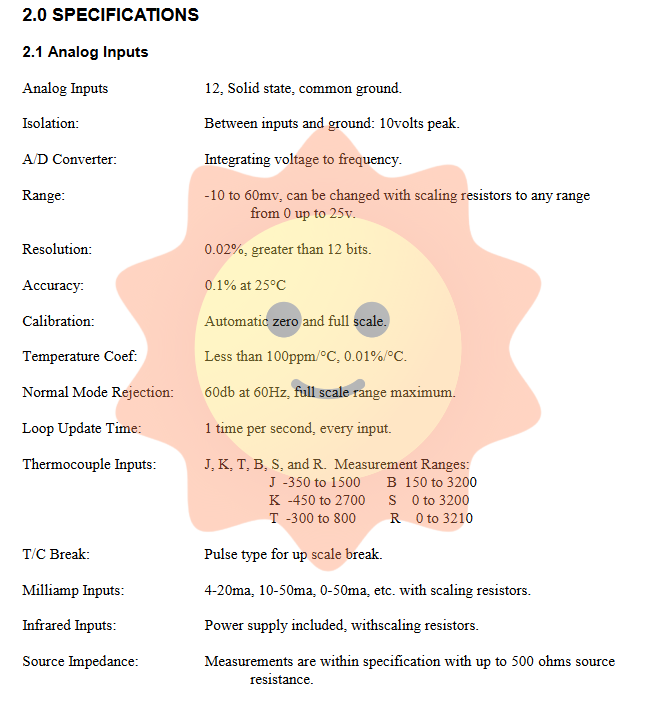

2. Technical Specifications and Hardware Architecture

Understanding the hardware layer of the 12LS is essential for any field engineer tasked with maintenance or system integration. The unit is characterized by its high-density I/O and modular sensor support.

Physical Installation and Power Requirements

Proper physical orientation and grounding are critical to ensure signal integrity. The manual specifies that the unit should be mounted in a vibration-free environment with adequate ventilation to prevent thermal drift in the analog-to-digital conversion circuitry.

| Parameter | Specification |

|---|---|

| Power Input | 12-24VDC (Standard) |

| Number of Loops | 12 Independent PID Loops |

| Operating Temp | 0°C to 50°C (Ambient) |

| Communication | RS-232C / RS-422 Serial Interface |

3. Advanced Control Logic: PID Tuning and Algorithm

The core value of the 12LS lies in its PID implementation. Unlike simple on/off controllers, the 12LS utilizes a sophisticated mathematical approach to maintain process variables at the desired setpoint.

Proportional, Integral, and Derivative Gains

Each loop can be individually tuned to accommodate the thermal lag and inertia of the specific process. The manual emphasizes that "Derivative" action is particularly useful in systems with large time constants, as it anticipates changes in the process variable.

4. Sensor Integration and Signal Conditioning

The 12LS interface board is designed to handle extremely low-voltage signals from thermocouples. To maintain accuracy, cold-junction compensation (CJC) is integrated into the hardware, ensuring that the ambient temperature at the terminal block does not skew the readings.

5. Serial Communications and System Integration

For its era, the ANAFAZE 12LS provided advanced networking capabilities. Through its serial ports, it could be connected to a host computer for centralized monitoring and data logging.

RS-232C: Primarily for point-to-point communication with a local PC.

RS-422: Used for longer distances and multi-drop configurations where multiple controllers are networked together.

The protocol utilizes a robust command-response structure, allowing the master system to poll process variables, update setpoints, and acknowledge alarms in real-time.

6. Maintenance and Troubleshooting

Long-term reliability of the 12LS requires periodic inspection of the terminal connections and verification of the sensor calibration. Common issues often relate to "Open Sensor" errors, which the 12LS detects by monitoring the impedance of the input loop.

When troubleshooting, the manual recommends checking the power supply stability first, as fluctuations in the DC bus can lead to erratic PID behavior and communication timeouts.

7. Conclusion: The enduring value of the 12LS

While newer technologies have emerged, the ANAFAZE 12LS remains a testament to durable industrial design. Its combination of high loop density, flexible I/O, and reliable PID control makes it a valuable asset in legacy systems across the plastics, food processing, and semiconductor industries.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor