Zygo MicroLUPI Micro Hole Diameter Laser Unequal Path Interferometer

The MicroLUPI is a versatile and precise instrument used for testing spherical and flat optics. It can be configured to measure surface figure and radius of curvature of individual optical parts or optical arrays.

The MicroLUPI has a 3 millimeter diameter,collimated measurement beam. All MicroLUPI’s come with a granite base, a stable gantry column, motorized focus control, and X/Y motorized stage.

Key technical parameters

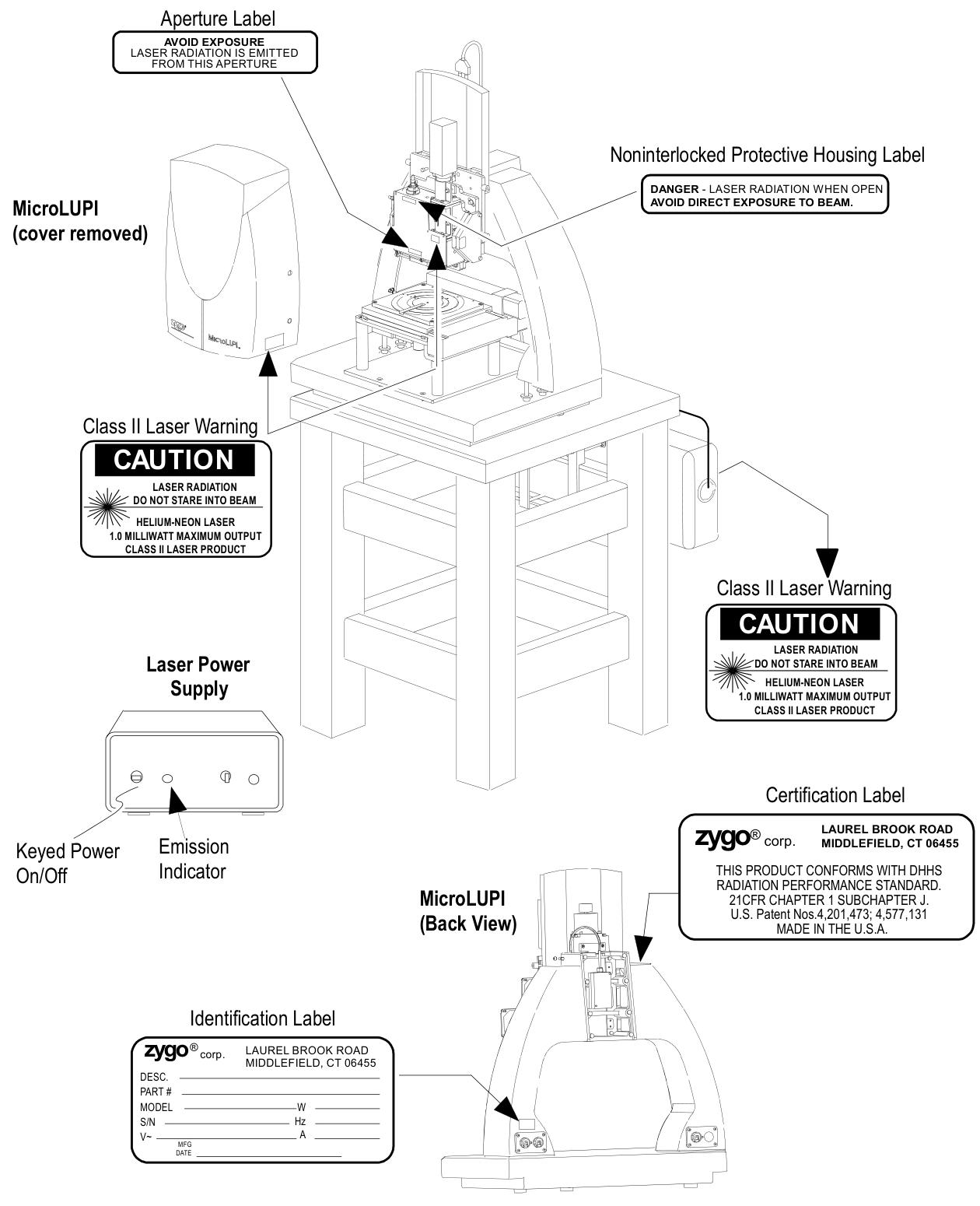

Laser: Stable frequency helium neon laser (fiber output), power ≤ 1mW, coherence length ≥ 10m

Motion system: The X/Y stage and Z-axis focusing are both driven by DC brushless micro stepper motors, with a stroke of 152mm (6 inches), a resolution of 0.1 μ m (4 μ in), and a maximum speed of 12.7mm/s (0.5in/s)

Imaging and Observation: Maximum 640 × 480 pixel camera, 9-inch monochrome video monitor for real-time display, supports manual/auto focus

Environmental requirements: temperature 15-30 ℃ (59-86 ° F), temperature change rate<1.0 ℃/15 minutes, humidity 5% -95% (no condensation), vibration isolation frequency 1-120Hz

Laser safety: Complies with DHHS Class II laser standards, emits only visible red light, and has no visible radiation

Installation and initialization

1. Preparation before installation

Environmental requirements: Concrete floor should be used to reduce vibration, avoid air conditioning/fan direct blowing causing airflow disturbance, and stay away from optical pollution sources such as smoke and dust

**Utility requirements * *: 100-240VAC 50/60Hz power supply (with grounding), vibration isolation table requires ≥ 60psi compressed air (1/4 inch interface), vacuum suction cup requires 1/8 inch NPT interface vacuum source

Installation restriction: The device must be operated by Zygo trained personnel, and after opening the box, it must be left to stand in the installation environment for 24 hours to adapt to temperature and humidity

2. Core installation steps

Position the vibration isolation system and workbench, and install the granite base, column, Z-axis stage, and MicroLUPI machine head in sequence

Connect the laser power supply, motion controller, motor driver and other cables, ensure that the hardware key is connected to the parallel port of the computer, and the controller board cables are correctly connected

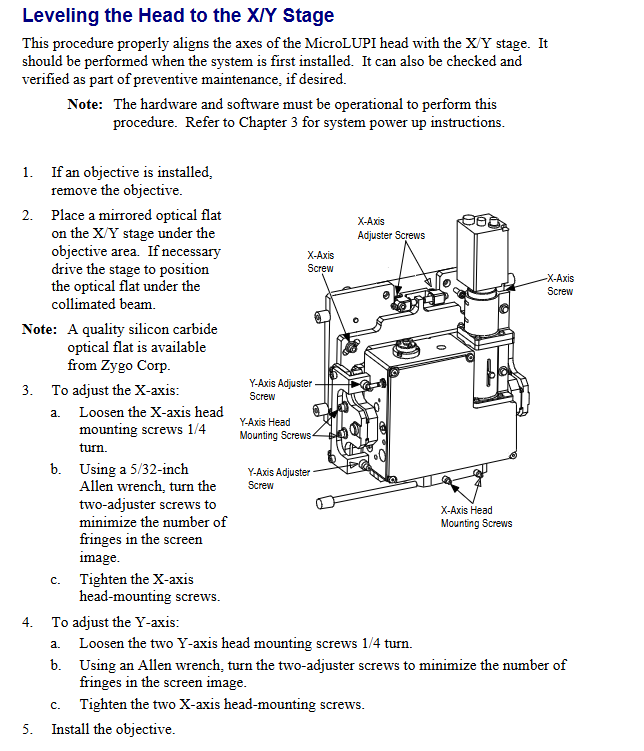

Install the objective lens (align with the dovetail groove pin and tighten the locking screw), adjust the working distance of the objective lens (match the engraved line according to the nominal curvature radius of the measured part)

Calibrate the machine head and X/Y stage: After removing the objective lens, place the optical flat mirror and adjust the X/Y axis adjustment screws to minimize the number of interference fringes

3. Startup initialization process

Turn on the laser power with the key and wait for the "Locked" indicator light to turn on; Turn on all components through the power manager

Log in to Windows NT on the computer (default username "zygo"), open MetroPro software and load MicroLUPI.app application

Perform X/Y stage and Z-axis "home" operation, set Z-axis collision protection (move the objective lens to a slightly smaller distance than the working distance, press the Z Stop button until the green light stays on)

Measurement operation process

1. Basic operation preparation

Controller usage: Adjust the height of the objective lens through the Z-axis joystick (push/pull to control lifting, deflection amplitude to control speed), move the stage with the X/Y joystick, and the emergency stop button (Motion Stop) can interrupt all movements

Light intensity adjustment: Press F4 to open the light intensity window, adjust all indicators to green through the numeric keypad (to avoid saturation and data loss), and F5 can automatically set the light intensity

2. System error calibration (key steps)

Calibration purpose: To eliminate inherent errors in the optical system of the instrument and improve measurement accuracy, recalibration is required after replacing the objective lens, adjusting the camera mode/phase resolution, or changing the ambient temperature

Operation steps:

Place the Zygo standard reference ball (avoid touching the optical surface), adjust X/Y/Z to align the center of the ball and hide the stripes

Set the average number of phase measurements in the measurement control window (recommended to be 3 times that of regular measurements, with a minimum of 8 times), and turn off "Subtext Sys Error"

After measuring with F1, save the data (named in a format such as "SysErrLN1x. dat" to distinguish between camera mode and phase resolution). During subsequent measurements, enable "Subtext Sys Error" and load the corresponding error file

3. Typical measurement scenarios (curvature radius of spherical parts)

Select the matching objective lens (50X working distance 13.8mm, 100X working distance 4.7mm), place the test piece and center it through the stage control lever

Enable AutoNULL (optional Power/Focus mode), set Lateral Pass Limit and Power/Focus Pass Limit

Click on "Auto Calibrate" to calibrate the X/Y/Z calibration coefficients (the fitting quality should be close to 1), and execute AutoNULL to optimize the stripes

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands