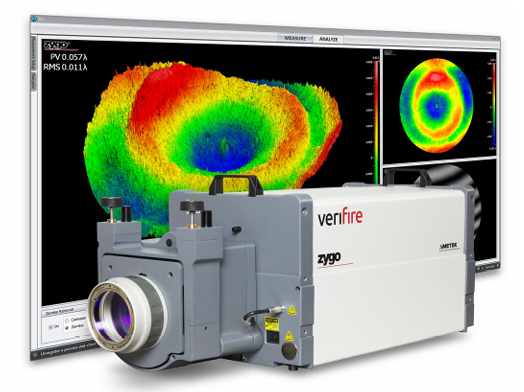

Zygo Verify Laser Interferometer Product Highlights

Zygo Verify Laser Interferometer Product Highlights

Product core positioning

Zygo Verify is an industrial grade high-power Fizo interferometer, with the core advantage of being equipped with patented QPSI ™ The (Fast Phase Shift Interference) acquisition technology can achieve true coaxial common optical path surface morphology measurement in vibration environments, and is compatible with the traditional PSI (Phase Shift Interference) 13 bucket algorithm, balancing measurement accuracy and anti-interference ability. It is suitable for surface morphology detection scenarios of precision optical components.

Key system parameters

1. Optics and acquisition system

Parameter category 4-inch (102mm) model 6-inch (152mm) model supplementary explanation

Test beam diameter of 4 inches and 6 inches to meet the detection requirements of optical components of different sizes

Align the field of view (FOV) ± 3 degrees ± 2 degrees to assist in rapid positioning of the test piece and ensure alignment of the optical path

The optical centerline distance is 4.25 inches (108mm), and the fixed size is 4.25 inches (108mm) to ensure the stability of the measurement optical path

Camera parameter resolution 1024 × 1024 pixels, 8-bit digitization, frame rate 100Hz, same as 4-inch model, high frame rate supports fast data acquisition, 8-bit digitization ensures grayscale accuracy

Collection time 130-300ms 130-300ms Fast response improves detection efficiency

The magnification can be adjusted from 1 to 6 times, and the observation accuracy can be adjusted according to the detailed requirements of the measured object

Polarization pupil close to circular (1.2:1 or better) ensures beam polarization consistency and reduces measurement errors

Focusing range ± 2.5m ± 5.5m. The 6-inch model has a wider focusing range and is suitable for large-sized components

2. Laser source parameters

Type: High power stable helium neon (HeNe) laser, compliant with ANSI Class 3R safety requirements (Class IIIa)

Wavelength: 633nm (red light band, suitable for most optical component reflection/transmission measurements)

Frequency stability: < 0.0001nm, extremely low frequency drift ensures long-term measurement accuracy

Output power:<5mW, high power enhances signal strength, compatible with low reflectivity components

Coherence length:>100m, long coherence length supports large optical path difference measurement scenarios

Operating environment requirements

Remarks on specific requirements for environmental indicators

Stable operation is required within the temperature range of 15-30 ℃ (59-86 ℉). If performance indicators need to be met, it is recommended to set the temperature at 20-23 ℃ (performance verification reference temperature)

Temperature change rate<1.0 ℃/15 minutes to avoid rapid temperature changes that may cause thermal expansion and contraction of equipment components, affecting measurement accuracy

Humidity 5% -95% relative humidity, no condensation to prevent moisture from causing mold on optical components and short circuits in electronic components

Under vibration isolation QPSI technology, no additional vibration isolation is required; It is recommended to configure QPSI technology as the core anti vibration advantage in PSI acquisition mode to reduce the vibration control requirements for the installation environment

Measurement performance indicators (based on a stable temperature environment of 20-23 ℃)

Specific numerical definitions and calculation criteria for performance parameters

Perform 36 consecutive measurements (16 averages) on a 4-inch short planar cavity with RMS simple repeatability ³<0.06nm (λ/10000, 2 σ), and take 2 times the RMS standard deviation

RMS wavefront repeatability ⁴ < 0.35nm (λ/1800, mean+2 σ), the mean difference between all even numbered measurements and the "composite reference value of odd numbered measurement mean" in 36 consecutive measurements (16 averages), plus 2 times the standard deviation

In the pixel level standard deviation graph of 36 consecutive measurements (16 averages) with peak pixel deviation ⁵<0.5nm (λ/1200, 99.5 percentile), the deviation value corresponding to 99.5 percentile reflects the temporal variability (Class A uncertainty)

Physical and configuration information

1. Physical specifications

Model size (length x width x height) Weight

4 inches 69 × 31 × 34cm (27.3 × 12.1 × 13.4 inches) ≤ 85 pounds (38kg)

6 inches 92 × 31 × 34cm (36.4 × 12.1 × 13.4 inches) ≤ 100 pounds (45kg)

2. Hardware and software configuration

Computer: High performance Dell PC, equipped with Windows 10 system

Software: 64 bit Mx ™ Software that provides measurement control, data processing, and result analysis functions

Control accessories: iOS system touch screen intelligent remote control (wireless); 1-5 times zoom/focusing component with encoding (suitable for mass production part inspection)

Optional accessories: vibration isolation device (to be used with compressed air), other specialized testing accessories (see Zygo accessory guide for details)

3. Compressed air demand (optional for vibration isolation)

Pressure: 80psi (5.5bar)

Requirement: Dry and filtered air source to avoid moisture/impurities damaging vibration isolation components

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands