Welcome to the Industrial Automation website!

Product

Article

NameDescriptionContent

Zygo MicroLUPI Micro Hole Diameter Laser Unequal Path Interferometer

The ZYGO MicroLUPI (1) is a micro-aperture laser unequal path interferometer (LUPI). It is a phase shifting interferometer designed for non-contact, high speed automated measurement of micro-optics.

The MicroLUPI is a versatile and precise instrument used for testing spherical and flat optics. It can be configured to measure surface figure and radius of curvature of individual optical parts or optical arrays.

The MicroLUPI has a 3 millimeter diameter,collimated measurement beam. All MicroLUPI’s come with a granite base, a stable gantry column, motorized focus control, and X/Y motorized stage.

The MicroLUPI is a versatile and precise instrument used for testing spherical and flat optics. It can be configured to measure surface figure and radius of curvature of individual optical parts or optical arrays.

The MicroLUPI has a 3 millimeter diameter,collimated measurement beam. All MicroLUPI’s come with a granite base, a stable gantry column, motorized focus control, and X/Y motorized stage.

Zygo MicroLUPI Micro Hole Diameter Laser Unequal Path Interferometer

The MicroLUPI System

The ZYGO MicroLUPI (1) is a micro-aperture laser unequal path interferometer (LUPI). It is a phase shifting interferometer designed for non-contact, high speed automated measurement of micro-optics.

The MicroLUPI is a versatile and precise instrument used for testing spherical and flat optics. It can be configured to measure surface figure and radius of curvature of individual optical parts or optical arrays.

The MicroLUPI has a 3 millimeter diameter,collimated measurement beam. All MicroLUPI’s come with a granite base, a stable gantry column, motorized focus control, and X/Y motorized stage.

Options

Objectives:50X SLWD, 0.45 NA (0.38 NA useable), Objective 100X SLWD, 0.73 NA, Objective (SWLD = Super-Long Working Distance)

Wavelength:Custom from blue to near-IR. (632.8 nm standard)

Z-axis Digital Indicator:Incremental z-axis length gauge for high-accuracy radius of curvature measurements. (standard on some models)

Vacuum Chuck:Stage vacuum chuck to hold 3, 4, or 6 inch wafers.

MicroLUPI

The MicroLUPI system can be broken down into two basic subsystems - the interferometer and the computer. The interferometer provides the raw data needed for analysis; it includes the interferometer itself, laser, laser power supply, objective, motorized X/Y stage, motor driver assembly, motion controller, and a vibration isolation system. The computer controls the measurement process, performs calculations, displays measurement results on a color monitor, and displays part images on a monochrome video monitor.

The MicroLUPI is designed to be used in a production environment with simple point and click control of the interferometer. Focusing is guided by a real-time display of the test part. A motorized stage simplifies aligning the part under the objective. Initiating a measurement is a single button operation.

The real power to analyze the measurement data lies in its MetroPro™ analysis and control software. MetroPro runs in a windows environment and has a graphical user interface. MetroPro performs image reconstruction and analyzes entire areas as well as profiles, and provides numerous numerical results. The MicroLUPI also provides flexible scripting capabilities for specific application needs.

How the MicroLUPI Works

The MicroLUPI is a TwymanGreen, unequal-path interferometer. Light from the laser is ported to the MicroLUPI head through a fiber optic cable. The laser beam is split into two beams by an internal beamsplitter. One portion exits the interferometer through the objective and reflects from the test surface back into the interferometer. The other portion reflects from an internal, high quality phase-shifting reference mirror assembly. Both portions are then recombined and directed onto a solid-state camera.

Due to surface irregularities, the test or measurement wavefront travels different distances. When the reference and measurement wavefronts are recombined, the waves are out of phase and form an interference pattern. This interference pattern between the two light wavefronts results in an image of light and dark bands, called fringes, that indicate the surface quality of the part being tested. Beam differences indicate surface topography and the variation from an “ideal” surface of the part being measured.

The phase-shifting reference mirror assembly uses a piezoelectric transducer (or PZT) to move the reference element forward and backward, causing constant phase variations between the reference wavefront and the measurement wavefront. The motion of the reference element is precisely controlled and is synchronized with the frame rate of the solid-state video camera. During a data acquisition sequence, the computer takes several “snapshots” of the interference pattern, each at a point when the interfering wavefronts have undergone a 90-degree phase shift in relation to one another.

These snapshots are processed in MetroPro by the computer to determine the phase of the wavefront at each point when the interfering wavefronts have undergone a 90-degree phase shift in relation to one another. The result is a very accurate map of the wavefront and therefore, the quality of the component being tested.

Measurements are three-dimensional. Vertical measurements, normal to the surface, are performed interferometrically. Lateral measurements, in the plane of the surface, are performed by calculating the pixel size from the field of view of the objective in use. Results are displayed on a color display as solid images, plots, and numeric representations of the surface or wavefront.

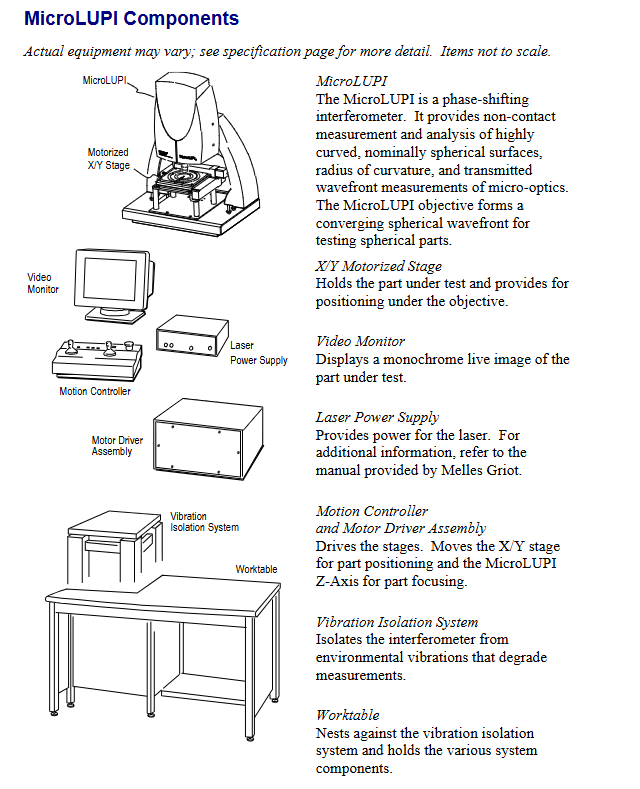

MicroLUPI Components

The MicroLUPI is a phase-shifting interferometer. It provides non-contact measurement and analysis of highly curved, nominally spherical surfaces, radius of curvature, and transmitted wavefront measurements of micro-optics. The MicroLUPI objective forms a converging spherical wavefront for testing spherical parts.

X/Y Motorized Stage

Holds the part under test and provides for positioning under the objective.

Video Monitor

Displays a monochrome live image of the part under test.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands

236

+86-153-9626-8993

WeChat

Contact

Whatsapp

After years of experience, it has developed into a group enterprise entity integrating equipment, industrial, chemical, petroleum equipment, electricity and other products trade and services.

KONG JIANG

Product

Copyright © 2023 KongJiang Group All Rights Reserved .