Welcome to the Industrial Automation website!

Product

Article

NameDescriptionContent

Zygo Device Standard Operating Procedure (SOP)

To The right is the motion controller/joystick Check the controller to make sure the z-stop is set (light above z stop button is solid green or solid red).

This is done as a safety precaution as you prepare your sample.

The z-stop must be set before any measurement steps.

This is done as a safety precaution as you prepare your sample.

The z-stop must be set before any measurement steps.

Zygo Device Standard Operating Procedure (SOP)

Start up

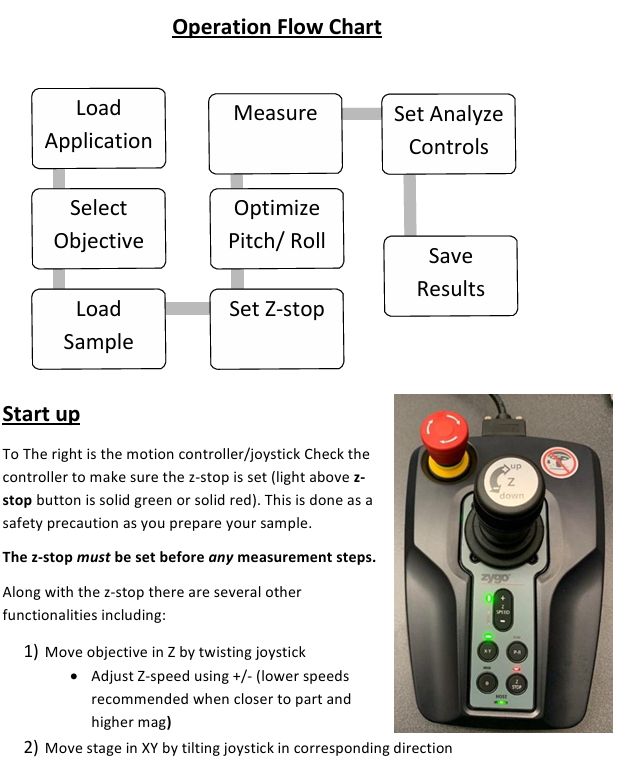

To The right is the motion controller/joystick Check the controller to make sure the z-stop is set (light above z stop button is solid green or solid red).

This is done as a safety precaution as you prepare your sample.

The z-stop must be set before any measurement steps.

Along with the z-stop there are several other functionalities including:

1) Move objective in Z by twisting joystick

• Adjust Z-speed using +/- (lower speeds recommended when closer to part and higher mag)

2) Move stage in XY by tilting joystick in corresponding direction

• XY button must be selected (green light above button)

3) Move stage in PR by tilting joystick in corresponding direction

• PR button must be selected (green light above button)

• P=pitch, R=roll (max +/-2 degree)

• Rotate stage, 𝜃, is not functional on our instrument

4) Emergency Off button to cancel the actions taken (Stage will need homed afterwards)

Loading Application

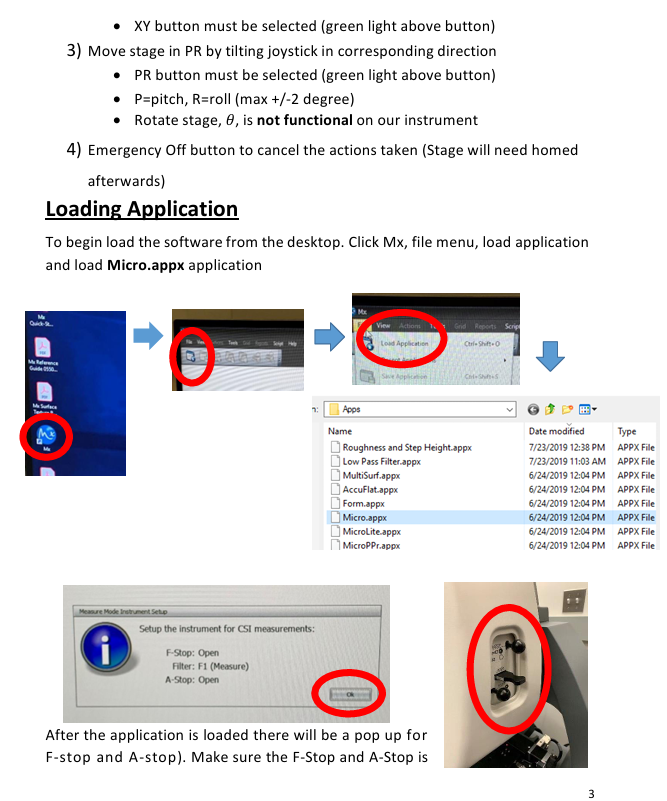

To begin load the software from the desktop. Click Mx, file menu, load application and load Micro.appx application

After the application is loaded there will be a pop up for F-stop and A-stop). Make sure the F-Stop and A-Stop is open (push knobs in) and the filter is set to F1 (measure) as shown on above. Select ok.

Select Objective

Use the software to select the objective you wish to use. The options are 2.5x, 20x, and 50x. There is an internal zoom lens (0.5X, 1X, 2X) to reach finer magnification steps. It’s recommended that you start with the 2.5x objective, 0.5X zoom, and increase in smaller increments. You must always raise the objective high in z before switching objectives to prevent collision.

Load Sample

Ensure objective is sufficiently high. Place sample on stage and align XY rotation by eye since no θ rotation is available. Adjust X and Y on joystick until light from objective is projected onto sample.

Set Z-stop

The Z-Stop has 3 settings noted by the indicator light:

• Blinking red: the z-position is not set (you will also hear an audible beeping sound when trying to move the objective)

• Solid red: the z-position is at the user-set limit

• Solid green: your current position in the z axis is higher than the set z-stop

Procedure:

1) Drive the objective down slowly in Z from a high position (speed can be adjusted on the Motion Controller). Select Auto Light Level (F9).

2) Drive until a surface on sample comes roughly into focus. Slowly drive below that surface and below any features of interest, being careful not to collide with any part of the sample or stage. Look at the bottom computer monitor and part on the stage to do this.

3) Set Z-stop (button on Motion Controller from blinking red to red)

Optimize Pitch/Roll

1) Drive in XY to cleanest, flattest area on your surface.

2) Focus the sample and find the fringes.

3) Select lowest internal zoom possible (0.5X).

4) Select PR. Drive in direction that adjusts fringes, so they are perpendicular on monitor (like shown in figure right). Hint: probe joystick lightly in several directions, trying 45-degree angles first as shown.

5) Lightly adjust Z (rotate joystick) to move fringes left and right to center of screen. (Can decrease z-speed).

6) Drive joystick perpendicular to fringes (left or right), such that they expand. Expand until there is only one fringe (doesn’t matter which).

7) Auto Light Level (F9) to get rid of red saturation on sensor.

8) Your surface is now normal to the objective, and you are ready to take a measurement.

Measure

In the measurement Setup panel on the left

1) Z resolution is High (there is a fine and coarse z-motor that moves the objectives while recording measurements. High uses fine, piezo motor)

2) In the measurement range drop box, select a range <145µm to keep high Z resolution. Above this will be coarse.

3) Ensure that “Enable stich” box is unchecked. Select Measure noted by the blue circle on Mx Pro (F12).

If software begins to do anything you don’t expect, hit red button on the motion icon controller (takes only 2 min to reset.

Set Analyze Controls

Navigate to the “Analyze” tab in MxPro software. The measurement you just took shows in 3D in the main window, 2D in the top right window, and brightfield in bottom right. You can load prior measurements by selecting Load and then loading a .datx file saved earlier. You will likely need to further level your data with post processing.

2D leveling

1) Right-click on main window 3D figure and select 2D.

2) Select “Linear” above window.

3) A slice with arrows will appear. Click in two positions on your image to select the measurement of interest. Note graph below will automatically plot the profile.

4) Right click on graph, add inspector 1. Right click again and add inspector 2.

5) Slide around to your baseline surface. Right click, Level.

3D leveling

1) In the left panel you are in the “Surface” section. Select “Surface Processing” (pop up window appears)

2) Check “Immediate Update” in bottom left. Check “Use Fit Mask.” Select Mask Editor. A window will pop up.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands

236

+86-153-9626-8993

WeChat

Contact

Whatsapp

After years of experience, it has developed into a group enterprise entity integrating equipment, industrial, chemical, petroleum equipment, electricity and other products trade and services.

KONG JIANG

Product

Copyright © 2023 KongJiang Group All Rights Reserved .