How to unpack and install the Zygo Mark II 4-inch interferometer system?

Video monitor: Display real-time interference patterns collected by the host, 9-inch diagonal screen, equipped with a universal bracket, can be placed on the desktop or installed above the host through a dedicated lifting bracket, supporting flexible adjustment of viewing angle to optimize observation effect.

Optional VP-2 video printer: uses specially coated paper to provide hard copy recording of interference fringe patterns for easy archiving and analysis.

Converter installation: Remove the transmission element from the converter, insert its short metal pin into the socket slot of the host accessory, push it in and rotate it to fix it, tighten the locking screw, align the tilt knob of the host accessory socket with the converter, and remove the flat reflector.

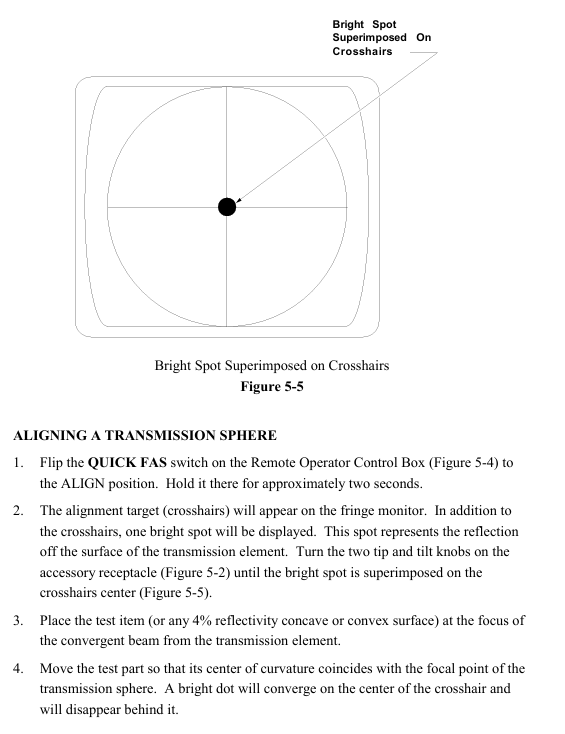

Component alignment: Install the transmission component on the converter, use the two tilt knobs at the aperture end of the converter (do not touch the host socket knob), and follow the "Transmission Component Alignment" process; If a transmissive sphere is installed on the converter, additional alignment checks are required: the test piece is placed at the focal point of the converging beam. In "VIEW" mode, if the target center pattern is offset, use the converter socket knob to adjust it. If the aperture is not full of the screen (vignetting), adjust it through the Zygo 3/5-axis bracket X/Y, and optimize the focusing method according to the spherical plane alignment. The final number of stripes is controlled between 0-7.

Interference pattern evaluation and geometric distortion inspection

Interference pattern evaluation: It is necessary to quantify the deviation between the test fringes and the ideal fitting pattern (usually expressed as a fraction of the ideal fringe spacing). It is recommended to refer to the "Interference Pattern Interpretation and Evaluation Manual AB-0001". Zygo provides real-time interference pattern evaluation equipment, and information can be requested as needed.

Geometric distortion inspection: Preheat the equipment for 30 minutes (the roundness change of the image during the preheating period is normal and does not need to be adjusted), remove the accessory socket transmission element, place a reference plane with two axis brackets (4% or 90% reflectivity) 12 inches away from the host, and align it with Quick FAS; Insert vertically arranged parallel thin lines (or adjustable parallelograms provided in the user manual) into the beam near the reference plane, zoom to 6x and restore to 1x, observe the monitor line pattern (which can be photographed by a video printer), and if there is non ideal distortion (such as aspect ratio deviation), refer to Service Manual SP-0038 for correction, or contact Zygo service department; If there is a ZAPP/PC system, the host signal can be directly evaluated (its circular mask should display as a perfect circle, and the host CCTV needs to be adjusted to fill the aperture image with the mask).

(3) Operation precautions

Do not touch the glass surface of optical accessories with bare hands. If touched without professional cleaning experience, do not clean it yourself (soft coating only has a reflectivity of 90% and is easily damaged); When not in use, the optical accessories should be returned to the protective box.

When installing optical accessories, avoid excessive force that may cause strain or damage to the components; When clamping attachments, do not tighten the screws too tightly to prevent deformation of the reference surface.

The accessories are lightly clamped with nylon screws on the two axis bracket. If the bracket tilts backwards, the accessories may fall off, so the bracket should not be moved or tilted when clamping the accessories.

The host needs to be used along the axis defined by the automatic alignment system, and the alignment accuracy must be ensured in the alignment mode, otherwise there may be no stripe display in the observation mode; The intensity of the two interfering beams needs to be close to obtain the best stripe contrast.

The distance between the test piece and the host should be moderate, shortening the optical path length of the last reflector and reducing the cavity length to reduce wavefront distortion caused by unstable air paths.

Maintenance and accessory management

(1) Daily maintenance

Appearance cleaning: clean the blue shell with a soft cloth dipped in a mild furniture polish, and clean the gray painted parts with a mild spray cleaner.

Component lubrication: The spring positioning pin after the socket clip of the host accessory needs to be lubricated with Lubriplate or similar lithium based bearing grease.

Optical component care: The main optical cabin is sealed, and the internal components are dust-proof; The attached optical components should be stored properly in a protective box to reduce the need for cleaning and the risk of damage; Clean only when the components are visibly dirty, prioritize cleaning the local area rather than the entire surface.

Optical cleaning process (to be strictly followed to avoid damage)

Cleaning materials (or equivalent): Orvus WA paste (KWW Warehouse Chemicals), distilled water, spectral grade methanol (Fisher Scientific A-408), spectral grade acetone (Fisher Scientific A-19), Multilith pad (Multigraphics # 200-847), lens paper (Aldine Papers 8 x 9 inches), vinyl gloves (Laminaire # 607).

Preparation: Before cleaning the special coating, check the protective instructions, remove the jewelry on your hands, thoroughly wash your hands, wear gloves, use clean filtered air to blow away loose particles on the optical surface, and check for residual pollutant types.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands