YOKOGAWA FA-M3 positioning module (with analog voltage output)

Document identification: Document number IM 34M6H58-01E, document model code DOCIM. This number must be referenced for communication and additional manual purchases; The media number is the same as the document number (CD version), and the copyright belongs to Yokogawa Electric in 1998.

YOKOGAWA FA-M3 positioning module (with analog voltage output)

Basic information and important statements

1. Applicable product and document identification

Applicable products: FA-M3 series unlimited range multi controller, specific models F3NC51-0N (single axis positioning module) and F3NC52-0N (dual axis positioning module), with the function of positioning control with analog voltage output.

Document identification: Document number IM 34M6H58-01E, document model code DOCIM. This number must be referenced for communication and additional manual purchases; The media number is the same as the document number (CD version), and the copyright belongs to Yokogawa Electric in 1998.

2. Important statement

Manual transmission: It needs to be transmitted to the end user. Before using the module, it is necessary to read the manual thoroughly to fully understand the product.

Content limitation: The manual only describes product functions and does not guarantee compatibility with specific user purposes; Without permission, partial or complete transcription or reproduction is not allowed; The content may change without prior notice.

Error feedback: Although we try our best to ensure the accuracy of the content, if any errors or omissions are found, please contact the nearest representative office or sales office of Yokogawa Electric.

Disclaimer: Yokogawa Electric only guarantees the product according to the separately provided warranty terms and is not responsible for direct/indirect losses caused by user use or unforeseeable defects of the product; The software is only for use on designated computers and is prohibited from reverse engineering, unauthorized transfer, etc.

Safety precautions

1. Definition of safety symbols

Meaning and usage scenarios of symbol types

CAUTION (product/manual) should follow the instructions in the manual to avoid personal injury, equipment damage, and other hazards such as electric shock prevention; The symbol in the manual is also used to indicate key information for understanding operations and functions

Warning (manual only): Please refer to the manual instructions to prevent hardware/software damage or system failure

TIP (manual only) provides information to supplement the current topic

SEE ALSO (manual only) indicates other sources of information to be referenced

2. Core security requirements

Grounding requirements: The functional grounding terminal (FG) must be grounded before use, and it must independently comply with Japanese Industrial Standards (JIS) Class 3 grounding, with a grounding resistance not exceeding 100 Ω, and avoid being grounded together with high-voltage power lines.

Installation environment: Avoid installation in locations with direct sunlight, temperatures exceeding 0-55 ℃, humidity exceeding 10% -90% (prone to condensation), corrosive/flammable gases, and mechanical vibrations/impacts.

Operation specification: The power must be turned off before installing/disassembling the module; Tighten the installation screws and terminal screws of the module to ensure that the interconnection cable connectors are secure and checked before powering on; An emergency stop circuit needs to be constructed using external relays to interlock with the controller status (stop/run); Avoid cleaning with solvents such as paint thinner, only wipe with a damp cloth or neutral cleaner.

Component replacement and modification: Only company designated components can be used for replacement, and it is prohibited to modify or add components to the interior of the product; The CPU module contains a built-in battery and should be stored in high temperature (storage temperature -20-75 ℃) and high humidity environments to prevent a sudden decrease in battery life.

Electrostatic protection: Before operating in a dry environment, touch the grounded metal to release static electricity.

Product specifications

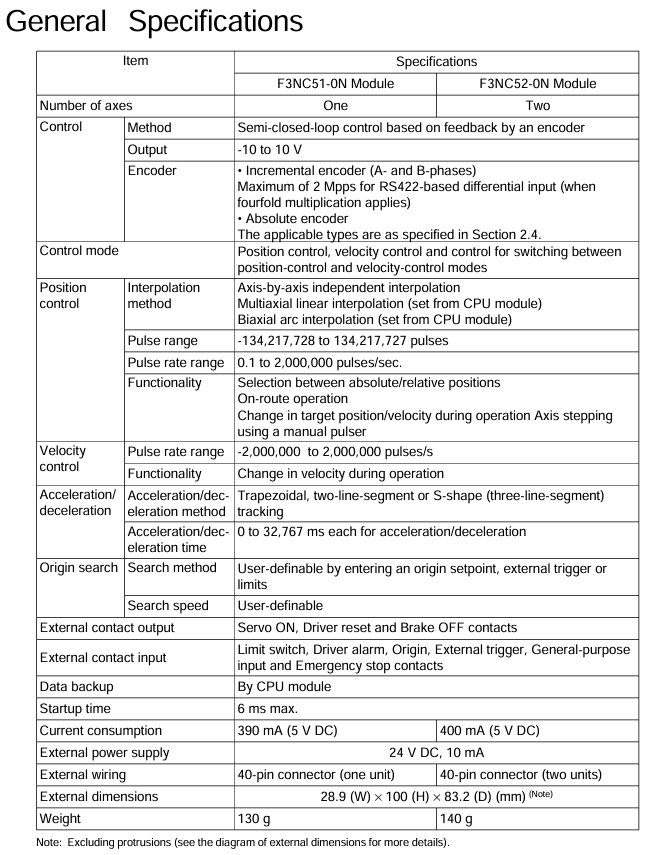

1. General specifications (core parameters)

Project F3NC51-0N (single axis) F3NC52-0N (dual axis) Description

Control the number of axes: 1 axis and 2 axes-

Control method based on encoder feedback semi closed loop control based on encoder feedback semi closed loop control-

Analog voltage output -10~10V -10~10V for speed control commands

Encoder compatibility incremental encoder (A/B phase, RS422 differential input, maximum 2Mpps at 4x); Absolute encoders (Yokogawa ∑ series, Sanyo Electric Manchester encoder series, etc., see Section 2.4 for details) are the same as single axis encoders-

Control mode position control, speed control, speed position control mode switching are the same as single axis-

Position control function axis independent interpolation, multi axis linear interpolation, dual axis arc interpolation; Pulse range -134217728~134217727 pulses; Pulse frequency ranging from 0.1 to 200000 pulses per second; Support absolute/relative position selection, operation in the path, target position/speed change during operation, manual pulse generator axis stepping with single axis-

Pulse frequency range for speed control function -2000000 to 2000000 pulses per second; Support speed changes during operation on the same single axis-

Acceleration and deceleration methods include trapezoidal, two-stage, and S-shaped (three-stage) tracking, with single axis acceleration and deceleration times ranging from 0 to 32767ms each

Origin search can be defined through the origin setting value and external triggering; Search speed: Users can set the same single axis-

External contact input limit switch, driver alarm, origin, external trigger, universal input, emergency stop contact are the same as single axis 24V DC, 4.1mA

External contact output servo ON, driver reset, brake OFF contacts are the same as single axis 24V DC, 0.1A

Data backup is handled by the CPU module on the same single axis-

Start time maximum 6ms maximum 6ms-

Current consumption 5V DC, 390mA 5V DC, 400mA-

External power supply 24V DC, 10mA 24V DC, 10mA-

External wiring 40 pin connector (1) 40 pin connector (2)-

Dimensions: 28.9 (width) x 100 (height) x 83.2 (depth) mm (excluding protrusions) Same as single axis-

Weight 130g 140g-

2. Model and suffix code

Model code suffix code type remarks

F3NC51-0N single axis position loop control, -10~10V voltage output, maximum speed 2Mpps

F3NC52-0N dual axis position loop control, -10~10V voltage output, maximum speed 2Mpps

3. Applicable encoders

Universal two-phase rotary encoder;

Yokogawa Motor serial absolute encoder (such as ∑ series);

Sanyo Motor serial absolute encoder (such as P series) or compatible models (such as Panasonic MINAS series, Manchester encoded serial transmission).

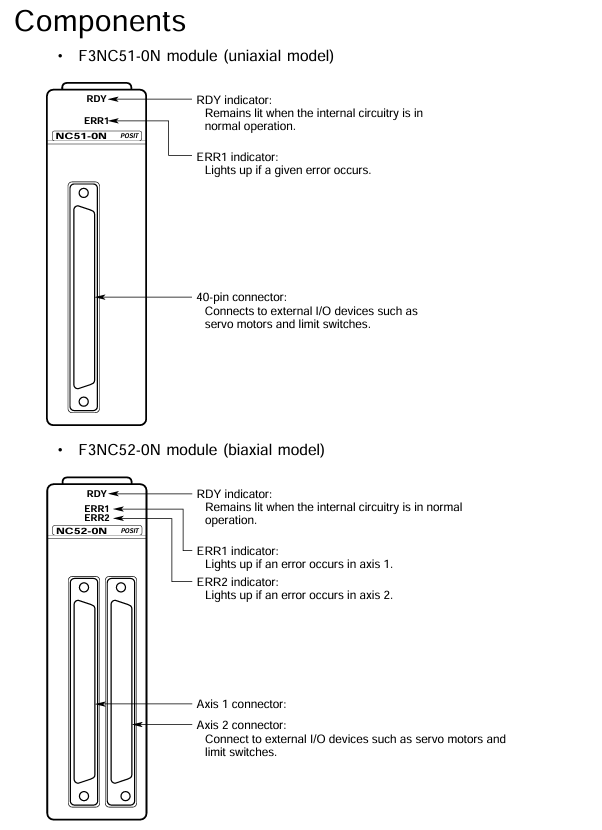

4. Module components and indicator lights

F3NC51-0N (single axis): RDY indicator light (always on when the internal circuit is normal), ERR1 indicator light (lit when an error occurs), 40 pin connector (connected to external I/O devices such as servo motors and limit switches).

F3NC52-0N (dual axis): RDY indicator light (normally lit), ERR1 indicator light (lit up for axis 1 error), ERR2 indicator light (lit up for axis 2 error), 2 40 pin connectors (corresponding to external device connections for axis 1 and axis 2 respectively).

Function Overview

The core functions of the module revolve around the position control, speed control, and mode switching of the motor, supporting various flexible operations, as follows:

Function Name Core Description Operation Points

The positioning operation is performed according to the instructions of the CPU module. After setting the target position, speed, acceleration and deceleration parameters, the "start operation instruction" relay is triggered. After the positioning is completed, the "positioning end" relay can be set to absolute/relative position; The acceleration and deceleration curves can be trapezoidal, two-stage, or S-shaped; Can set the positioning judgment range and timeout period; Support normal startup or waiting for internal/external trigger startup

Target position change during positioning operation, writing new positioning parameters and triggering the "Target Position Change Request" relay, can synchronously change speed, supports direction change (motor first stops urgently and then locates towards the new target position)-

Speed change during positioning operation, writing new target speed and triggering the "speed change request" relay to achieve real-time speed adjustment-

Speed control writes parameters such as target speed (negative speed corresponds to reverse rotation), acceleration and deceleration time, triggering the "start operation command" relay. The motor continues to rotate and needs to be terminated through "deceleration stop request" or "immediate stop request". Only incremental encoders are supported; Acceleration and deceleration curves are the same as positioning operations; Support normal startup or waiting for internal/external trigger startup

Speed change in speed control. During speed control operation, writing a new target speed and triggering the "speed change request" relay does not support direction change (need to slow down and stop first, then reset direction to start)-

Switching between speed and position control modes: During the operation of speed control, parameters such as target position, speed, acceleration and deceleration are written to trigger the mode switching command. The positioning operation can be set to normal switching or wait for external triggering switching when the instantaneous position is set to "0"; Support detection of Z-phase signal switching (Z-phase polarity and counting frequency need to be set)

Writing parameters such as target speed and acceleration/deceleration time in jog step, triggering the "positive jog step" or "negative jog step" relay. When the relay is disconnected, the motor decelerates and stops according to the parameters, which only takes effect when there are no errors, servo ON, positioning end, position control mode, and no other instructions are executed; Can only be terminated by "stop immediately", cannot be stopped by "slow down"

The emergency stop input module includes one emergency stop input (dedicated to the 1-axis connector, shared by both axes), which is a B-contact input and must be wired. Otherwise, the module will not work and the motor will stop immediately after triggering-

External contact input: 6 external contact inputs, functions can be defined through the "contact input mode" (such as limit, alarm, origin, trigger, etc.), polarity can be set separately, and status can be read through the application program-

External contact outputs 3 external contact outputs (servo ON, brake OFF, driver reset), triggered by corresponding commands, polarity can be set separately, and status can be read through the application program-

The SEN signal output is only used to connect the Yokogawa Motor absolute encoder and request the transmission of absolute value data. Other drivers need to be suspended when connected-

The origin search operation writes parameters such as search direction, speed, mode (contact input detection action), Z-phase edge selection, etc., triggering the "origin search" relay. After detecting the preset external contact input or Z-phase signal, it decelerates and stops. The detection position can be used as the origin (or origin offset value) to adjust parameters in multiple cycles to achieve complex search; In the absolute encoder system, the Yokogawa method can be searched with the incremental encoder, while the Sanyo method cannot be searched

The interrupt function supports "position detection interrupt" (interrupts the CPU when the instruction/encoder position reaches the set value) and "positioning end interrupt" (interrupts the CPU when positioning is completed). Please refer to the CPU manual for handling interrupts-

After triggering the "Manual Pulse Generator Mode ON" in manual pulse generator mode, the motor is controlled by the manual pulse generator, and the ratio of pulse input to motor movement is set by the "Manual Pulse Generator Proportional Value"; Dual axis can be set to this mode simultaneously, and the shared pulse input cannot control the motor through CPU instructions in this mode; Restore position control after mode OFF

Linear interpolation operation simultaneously writes target speed, position, acceleration and deceleration parameters in both axes (with the same acceleration and deceleration time, speed ratio=movement ratio), synchronously triggers the "start operation command" relay, and after each axis completes positioning, the corresponding "positioning end" relay acts-

Starting a new positioning operation during the operation of positioning in the path, the new operation is initiated before the end of the current operation, forming a path overlap (interval in the path), without the need to stop at the middle target position, and supporting direction changes requires determining the start timing through the "remaining deceleration time" status to avoid operation conflicts

The arc interpolation operation writes parameters such as the center position, radius, starting angle, and angle movement in both axes, synchronously triggering the "start operation command" relay. The module generates the arc path through trigonometric functions to ensure that the X/Y axis parameters are consistent (starting angle, angle movement, etc.); When a single axis error occurs, the other axis continues to run, and the program needs to detect the error and stop it

Parameter settings

The module parameters are divided into entrance parameters (usually set only once after power on), startup parameters (reference for instructions such as positioning/speed control execution), origin search related startup parameters, extended instruction parameters, control mode switching parameters, and arc interpolation parameters. The core parameters are as follows:

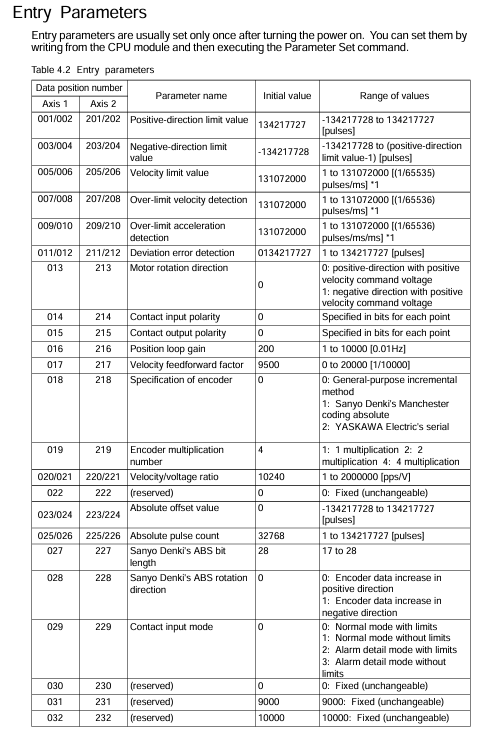

1. Entrance parameters (key items)

Parameter Name Axis 1 Data Position Axis 2 Data Position Initial Value Range/Description

Positive limit value 001/002 201/202 134217727-134217728~134217727 pulse, set the position limit within the physical stroke

Negative limit value 003/004 203/204-134217728-134217728- (positive limit value -1) pulse

Speed limit value 005/006 205/206 131072000~131072000 (1/65536) pulse/ms, limit path generation speed

Overspeed detection value 007/008 207/208 131072000~131072000 (1/65536) pulse/ms, detecting the actual speed of the motor exceeding the limit

Super acceleration detection value 009/010 209/210 131072000~131072000 (1/65536) pulse/ms/ms, detecting actual motor acceleration exceeding the limit

Deviation error detection value 011/012 211/212 134217727 1~134217727 pulses, detecting that the deviation between the instruction position and the encoder feedback position exceeds the limit

Motor rotation direction 013 213 0 0: Positive speed command voltage corresponds to forward rotation; 1: Positive speed command voltage corresponds to reverse rotation

Encoder specification 018 218 0 0: Universal incremental type; 1: Sanyo Manchester encoding absolute formula; 2: Yokogawa Serial Absolute Formula

Speed/voltage ratio 020/021 220/221 10240 1~2000000 pps/V, calculation formula: (rated motor speed x encoder pulses/minute) ÷ rated voltage

2. Other parameters (core items)

Startup parameters: including target speed, target position, target position mode (absolute/relative), acceleration and deceleration time/mode/parameters, positioning judgment range, timeout time, interpolation mode, startup mode, position detection mode/set value, etc. There is no initial value, which needs to be written before instruction execution.

Origin search parameters: including origin search mode (contact detection action), search direction, Z-phase edge selection, Z-phase pulse count, Z-phase search range, origin offset value, no initial value.

Extended instruction parameters: including extended instruction type (servo ON/OFF, brake ON/OFF, driver reset, etc.), static deviation adjustment, manual pulse generator proportional value, without initial value.

Arc interpolation parameters: including center position, radius, starting angle, angle movement, angle target velocity, acceleration and deceleration time, target position, correction pulse range, without initial values.

3. Example of parameter settings

Taking "motor rated speed 3000rpm, rated voltage 6V, encoder 8192 pulses/rev (4x), ball screw pitch 5mm/rev, operating range -500~1000mm" as an example, the key inlet parameters are calculated as follows:

Positive limit value: 1000mm ÷ 5mm/rev x 8192 pulses/rev=1638400 pulses;

Negative limit value: -500mm ÷ 5mm/rev x 8192 pulses/rev=-819200 pulses;

Speed limit value: (100mm/s ÷ 5mm/rev × 8192 pulses/rev) ÷ 1000 × 65536=10737418 (1/65536) pulses/ms;

Speed/voltage ratio: (3000rpm × 8192 pulses/rev ÷ 60s/min) ÷ 6V=68267 pps/V.

Status and I/O Relay

1. Status monitoring

The module status needs to be read through the CPU module, and the core status items are as follows (2-digit data needs to be read as "low word+high word", some of which are fixed-point data):

Status Name Axis 1 Data Position Axis 2 Data Position Description

Error status 101 301: Store error code when an error occurs, meaningless when there are no errors

Contact input status 103 303 stores the external contact input (including emergency stop) status, with 1 bit corresponding to 1 input and polarity defined by parameters

The current status of the instruction position is the path position generated by module 104/105 304/305, which is not the actual position of the motor and is measured in unit pulses

Encoder Position Current Status 108/109 308/309 Encoder Feedback Motor Actual Position, Unit Pulse

Target position status 112/113 312/313: The target position of the positioning operation (calculated according to the target position mode)

Extended state 114 314 stores operational states (acceleration/constant speed/deceleration, mode waiting, control mode, etc.), parsed bit by bit

Remaining deceleration time 115 315 Remaining deceleration time from positioning to target position, 0=path generation stop, -1=acceleration/uniform speed

2. I/O relay (interface CPU module)

Output relays (32 per axis, F3NC51-0N's 2-axis relay is invalid): The core includes start operation instructions (Y Ⅲ 33/49), extension instructions (Y Ⅲ 34/50), deceleration stop requests (Y Ⅲ 35/51), immediate stop requests (Y Ⅲ 36/52), origin search start (Y Ⅲ 37/53), etc., where III is the FA-M3 slot number where the module is located.

Input relays (32 per axis, F3NC51-0N 2-axis relays are meaningless): The core includes confirmation of start operation instructions (X Ⅲ 01/17), confirmation of extension instructions (X Ⅲ 02/18), confirmation of deceleration stop (X Ⅲ 03/19), end of origin search (X Ⅲ 05/21), end of positioning (X Ⅲ 14/30), error notification (X Ⅲ 12/28), etc.

Module access (CPU module interaction)

Supports accessing modules from both sequential CPUs and BASIC CPUs, with core operations including parameter read/write, state read, instruction triggering, etc., requiring adherence to specific instruction formats and operating procedures.

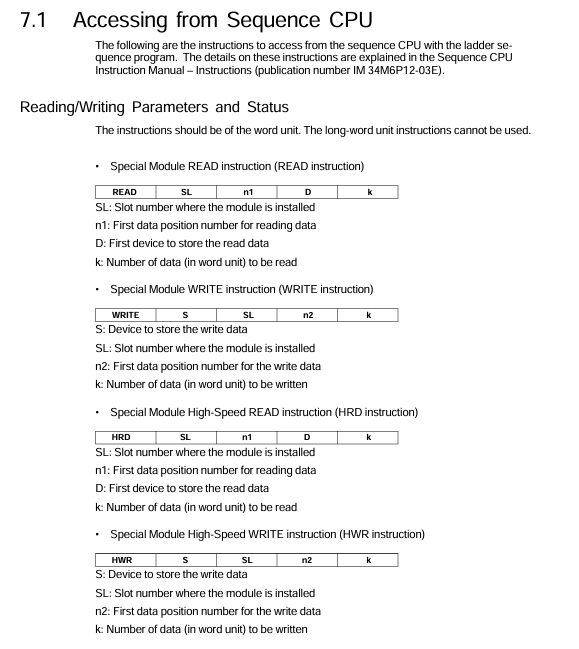

1. Sequential CPU access (ladder program)

Instruction types: Read for dedicated module, Write for dedicated module, Read for High Speed (HRD), Write for High Speed (HWR), INTP/IRET for interrupt handling.

Core operating procedures:

Parameter setting: Write parameters with the WRITE command → trigger the "parameter setting" relay → confirm the "parameter setting confirmation" relay → reset the relay (if the parameter is incorrect, it needs to be rewritten with the correct value);

Error reset: trigger the "error reset" relay → confirm the "error notification" relay reset → reset the relay (when the driver alarm error reset occurs, the driver reset signal is ON for 500ms and then OFF);

Positioning operation: Write the WRITE command to the start parameters → trigger the "start operation command" relay → confirm the "start confirmation" relay → reset the relay → wait for the "positioning end" relay to act;

Other operations: The processes of jog stepping, origin search, speed control, mode switching, etc. are similar, all of which require writing parameters (if necessary), triggering corresponding relays, confirming feedback, and resetting, and must meet the operating prerequisites (such as no errors, servo ON, etc.).

2. BASIC CPU Access (BASIC Program)

Instruction types: Module Usage Declaration (ASSIGN), Parameter/Status Read (ENTER), Parameter Write (OUTPUT), I/O Relay Read (STATUS), I/O Relay Write (CON), Interrupt Declaration (ON INT/GOSUB), Interrupt Reset (OFF INT).

Data processing: Two character data needs to be converted to a long integer (when read, it is a combination of "high character+low character", and when written, it is split into "high character+low character"); The core operations (parameter setting, error reset, positioning, etc.) logic is consistent with the sequence CPU, and process control is achieved through program loop detection of relay status.

Error codes and servo parameter adjustment

1. Classification and Handling of Error Codes

Module errors are divided into servo errors (related to motor motion, servo OFF triggered), parameter errors (invalid parameters during instruction execution, triggering error notifications), and parameter setting errors (invalid parameters during parameter setting, requiring rewriting of correct parameters). The core error codes are as follows:

Error type code, error description, handling suggestions

Servo error 12 driver alarm input detected. Check the cause of the driver alarm and perform error reset after resetting the driver

Servo error 13/14: Positive/negative limit input detected. Check the direction of motor operation and limit switch status to eliminate mechanical obstruction

Servo error 17/18 detected overspeed/over acceleration. Adjust the "overspeed detection value"/"over acceleration detection value" parameters to ensure that a buffer is left

Servo error 19: Deviation error detected. Check the position loop gain, speed feedforward coefficient, or adjust the "deviation error detection value"

Servo error 9999: Emergency stop triggered, execute error reset after releasing the emergency stop state

Parameter error: 10xx parameter is invalid (xx is the lower 2 bits of the parameter data position). Check if the corresponding parameter value is within the valid range and rewrite the correct value

Parameter setting error: 20xx Parameter setting is invalid (xx is the lower 2 digits of the parameter data position). Check the corresponding parameter values and logic between parameters (such as positive limit>negative limit), rewrite and execute parameter setting

2. Servo parameter adjustment

Parameter adjustment: Only the "position loop gain" (1-10000, 0.01Hz) and "velocity feedforward coefficient" (0-20000, 1/10000) can be adjusted, while other parameters are fixed values or set according to hardware specifications.

Adjustment process:

Preparation: Set the entrance parameters correctly according to the "Parameter Setting Example" and confirm that the servo drive is connected to the module normally;

Speed loop adjustment (servo drive side): Disconnect the module and adjust the speed loop according to the driver manual to ensure that the motor has no abnormal vibration;

Position loop adjustment (module side): Connect the module, with a default position loop gain of 200 (2Hz), gradually increasing to the maximum value where the motor has no abnormal vibration, and setting the servo OFF before adjustment;

Speed feedforward coefficient adjustment: default 9500 (0.95), no need for regular adjustment; The scenarios with high response requirements such as machine tools can be increased, and the problem of positioning overshoot needs to be reduced.

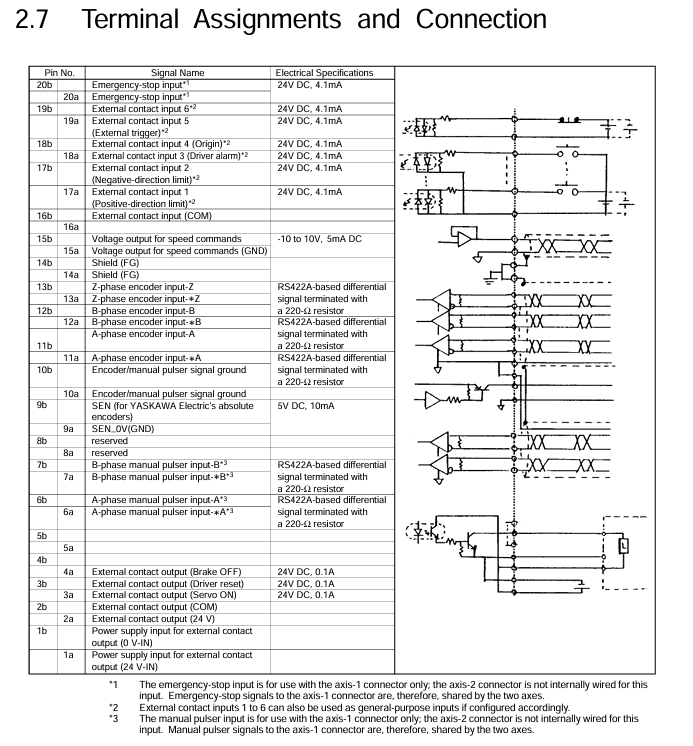

External contact signal connected to servo driver

1. Specification for External Contact Signal

Shielding (FG): Connect the frame grounding through the base module, and connect the shielded wires of the speed command voltage output and encoder input signals to this end;

Speed command voltage output: -10~10V, maximum load current 5mA, requires shielded twisted pair cable, GND to signal ground (SG);

Encoder/manual pulse generator signal ground (SG): connected to the encoder and manual pulse generator signal ground, and connected to FG through the backplane;

Encoder/manual pulse input: RS422 differential signal (220 Ω terminal resistor), input frequency ≤ 500kHz (2MHz after 4 harmonics), shielded twisted pair cable is required, A/B phase and speed command voltage phase need to be matched (B phase leads when positive voltage is applied);

External contact output: Common cathode open collector output, requires 24V DC external power supply, optocoupler isolation, maximum load current of 100mA/point;

External contact input: 24V DC, input impedance 5.6k Ω, optocoupler isolation, supports "+common" and "- common";

Emergency stop input: independent 24V DC B contact input (only valid for the 1-axis connector, shared by both axes), power supply of 16V DC or above and 3.2mA or above is required when the emergency stop is released;

SEN signal (Yokogawa absolute encoder): 5V DC output, maximum load current 10mA, used to request absolute value data.

2. Example of servo drive connection

The document provides three typical connection schemes, with the core being the "module driver motor encoder" signal closed-loop. The key connection points are as follows:

Yokogawa ∑ series driver (absolute encoder): module speed command (15B/15a) connected to driver V-REF/SG-V; Encoders A/B/Z phase (11b/11a, 12b/12a, 13b/13a) are connected to drivers PA0/* PA0, PB0/* PB0, PC0/* PC0; Servo ON (3a) connected to S-ON, driver reset (3b) connected to ALMRST, brake OFF (4a) connected to brake relay; Emergency stop (20A/20b) connected to the emergency stop switch; The SEN signal (9b/9a) is connected to the driver SEN/SEN_0V.

Sanyo P series driver (incremental encoder): module speed command (15B/15a) connected to driver VCMD/SG; Encoder A/B/Z phase (11b/11a, 12b/12a, 13b/13a) connected to drivers A+/A -, B+/B -, C+/C -; Servo ON (3a) connected to SON, driver reset (3b) connected to RST; Emergency stop (20A/20b) is connected to the emergency stop switch.

Sanyo P series driver (ABS-RII absolute encoder): Encoder A phase (11b/11a) connected to driver PS+/PS -; Other signals (speed command, servo ON, emergency stop, etc.) are connected to the incremental encoder and powered by a new encoder battery (BAT+/BAT -).

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

Email:wang@kongjiangauto.com