GE H201TI 220VAC Small on-line early warning transmitter

GE H201TI 220VAC Small on-line early warning transmitter

Overview of the GE H201TI Transmitter

The GE H201TI is a small - sized on - line early warning transmitter designed to operate with a 220VAC power supply. It plays a crucial role in monitoring and providing early warnings for various parameters in industrial or other relevant settings.

Function and Purpose

Monitoring Function

The primary function of this transmitter is to continuously monitor specific physical or chemical parameters. It could be used to measure variables such as temperature, pressure, flow rate, or the concentration of a particular substance. For example, in a water treatment plant, it might be used to monitor the chlorine concentration in the water supply. By constantly measuring the parameter, it provides real - time data that is essential for maintaining the quality and safety of the process or system.

Early Warning Capability

The H201TI is designed to provide early warnings. When the measured parameter approaches or exceeds a predefined threshold, it sends out an alert signal. This early warning system allows operators to take preventive measures before a critical situation occurs. For instance, if it's monitoring the temperature of a critical component in a manufacturing process and the temperature rises close to the maximum allowable value, it can trigger an alarm, enabling operators to adjust cooling systems or other relevant factors to avoid overheating and potential damage.

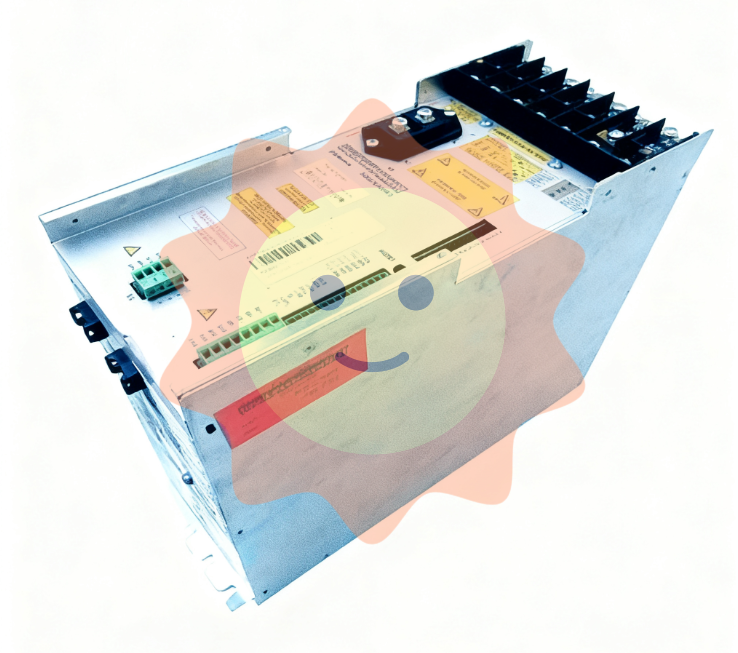

Technical Specifications

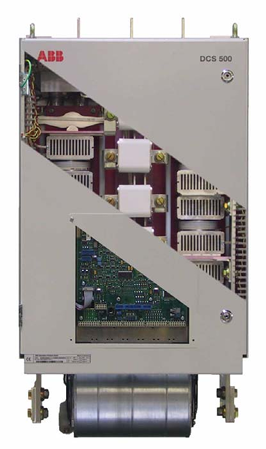

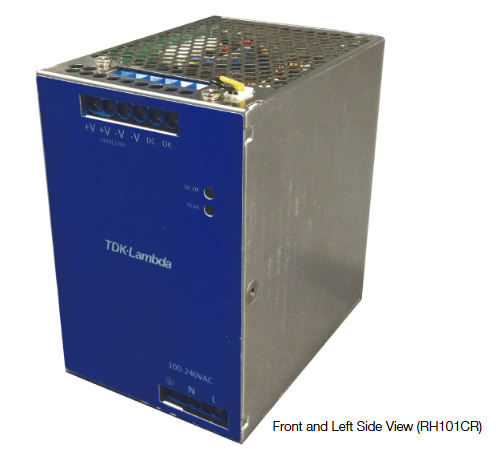

Power Supply

Operating with a 220VAC power supply, it has certain requirements and characteristics related to power input. The transmitter likely has internal circuitry to convert the AC voltage to the appropriate DC voltages needed for its internal components. It might also have power - filtering mechanisms to reduce electrical noise and ensure a stable power supply for accurate operation.

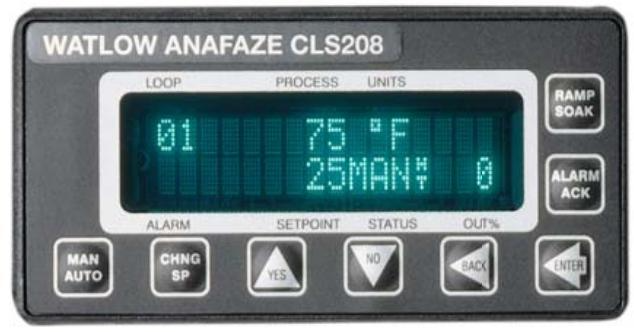

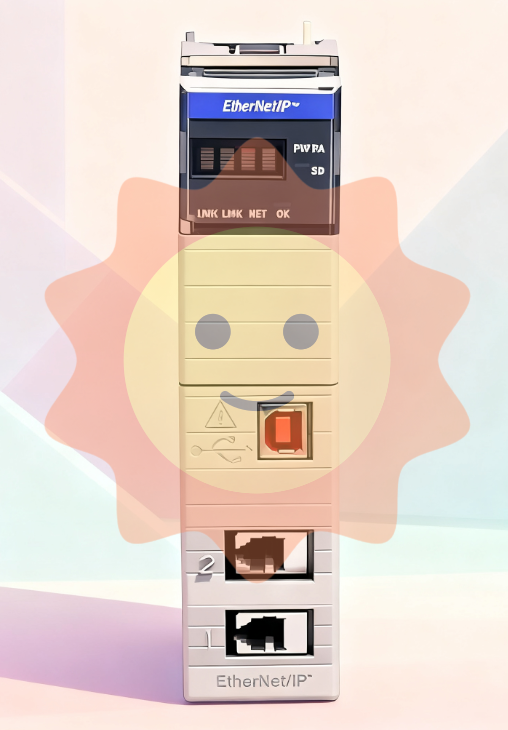

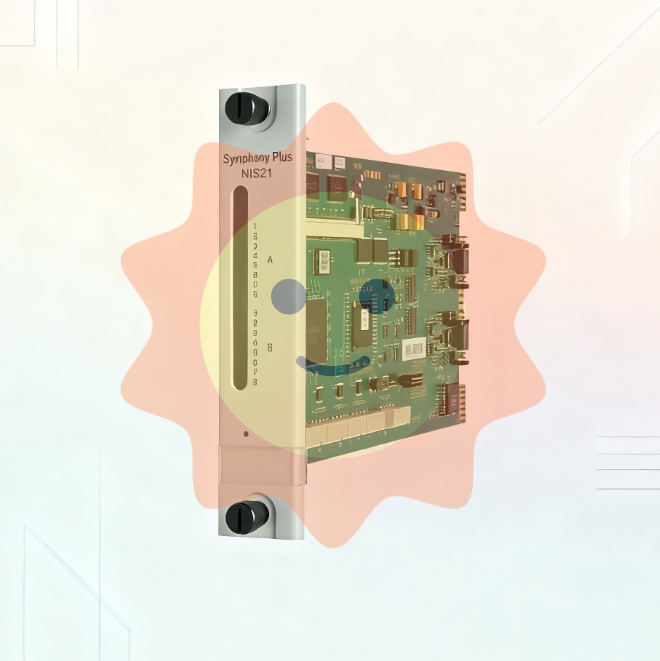

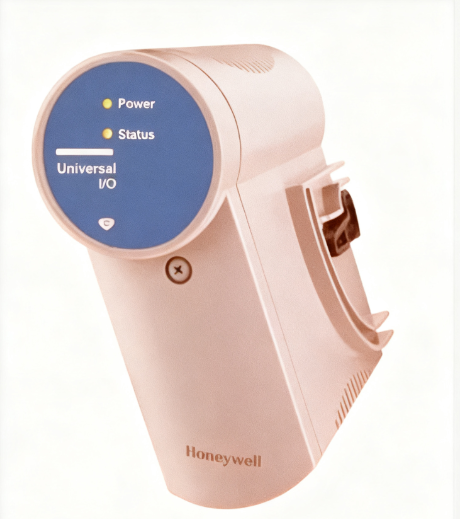

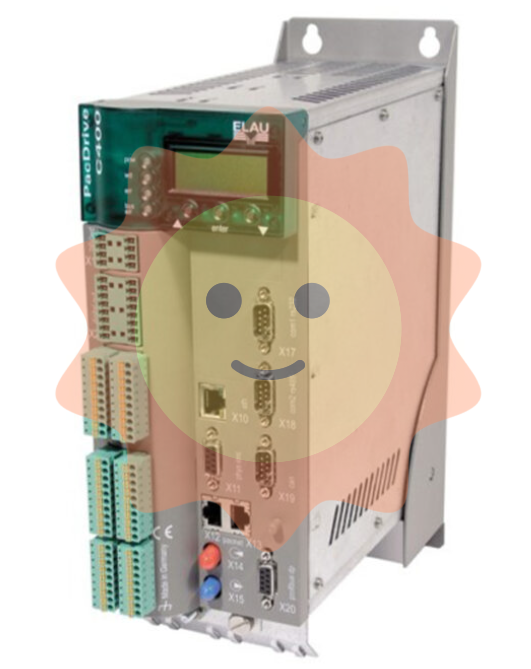

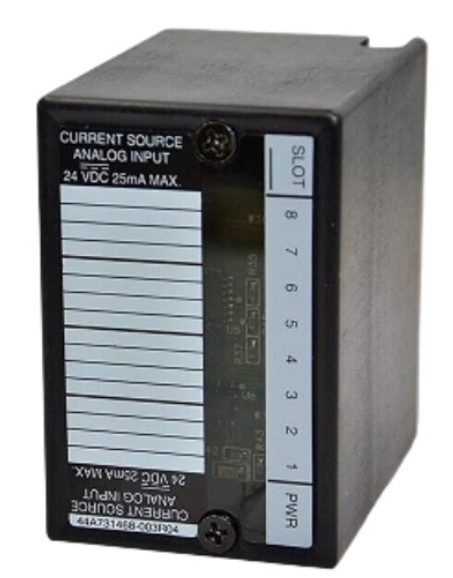

Signal Output and Communication

It produces an output signal that can be in various forms, such as a 4 - 20mA current loop signal or a digital signal depending on the configuration. The 4 - 20mA signal is a commonly used standard in industrial settings, where the current value represents the measured parameter value. In terms of communication, it may support protocols such as Modbus RTU or other simple serial communication protocols to transmit the measured data and warning signals to a central control system or a data - logging device.

Accuracy and Sensitivity

The H201TI has a defined level of accuracy in its measurements. For example, if it's measuring temperature, it might have an accuracy of ±1°C within a certain temperature range. Its sensitivity determines how small a change in the measured parameter it can detect. A high - sensitivity transmitter can pick up even minor fluctuations, which is beneficial for early warning purposes.

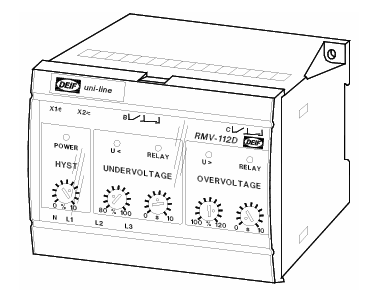

Physical Characteristics

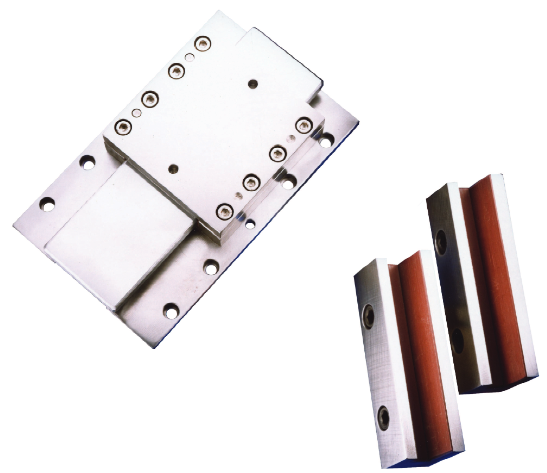

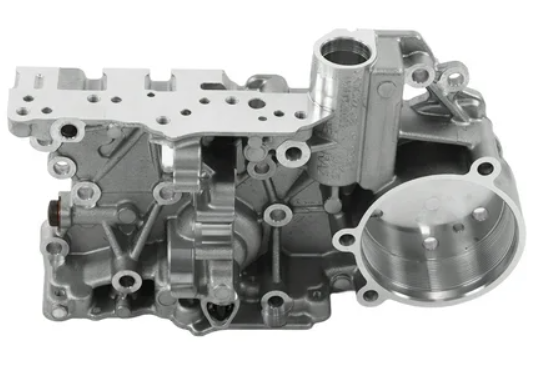

Size and Form Factor

Being a small - sized transmitter, it is designed to be easily installed in tight spaces or in locations where space is a constraint. Its compact form factor allows it to be mounted on pipes, walls, or equipment housings without taking up too much room. The dimensions might be in the order of a few inches in length, width, and height, depending on the specific design.

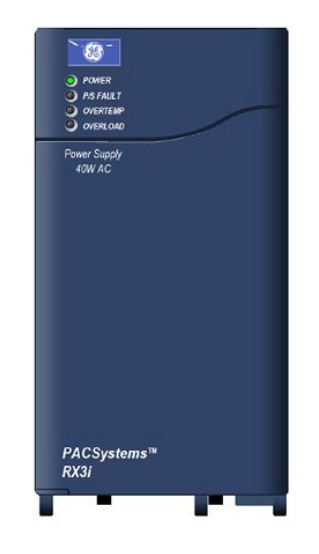

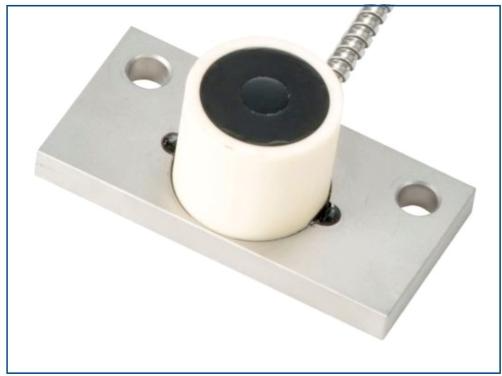

Enclosure and Protection

The transmitter is likely housed in a durable enclosure to protect it from environmental factors such as dust, moisture, and mechanical damage. The enclosure might have an ingress protection (IP) rating, such as IP65, which indicates a high level of protection against dust and water jets. This ensures its reliable operation in harsh industrial environments.

Applications

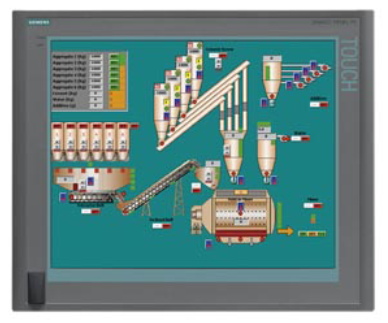

Industrial Process Monitoring

In industrial manufacturing processes such as chemical production, food and beverage processing, and metalworking, the H201TI can be used to monitor critical process parameters. For example, in a chemical reactor, it can monitor the pressure and temperature inside the reactor to ensure the safety and proper progress of the reaction.

In the pharmaceutical industry, it can be used to monitor environmental conditions such as temperature and humidity in clean rooms to maintain the quality of drug production.

Utilities and Infrastructure

In water and wastewater treatment plants, it can monitor water quality parameters such as pH, turbidity, and chemical concentrations. In power plants, it can monitor steam pressure, temperature, and flow rates to ensure the efficient and safe operation of the power - generation equipment.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com