WOODWARD 5009XT Fault-Tolerant Control

• Output relay failures can be detected and repaired with the turbine on-line.

5009XT Key Functionality

• Speed/frequency control

• Turbine or generator load control/limiting

• Extraction and/or admission header pressure control

• Turbine inlet header pressure control/limiting

• Turbine exhaust header pressure control/limiting

• Plant import/export power control/limiting

• Isochronous load sharing between units

• Any process directly related to unit load

• Proportional or integrating Servo Position Control with LVDT/RVDT excitation (with optional modules)

Operational Features

• Fault-tolerant I/O handling and processing

• Latent fault detection on relay outputs

• Time-stamped alarms, with 10ms resolution on trips

• Overspeed anticipation and shutdown protection

• Peak speed indication for overspeed trip

• Configurable over or under pressure shutdown logic

• Three Critical speed avoidance bands

• Patented OPTI Tune and OPTI Ratio algorithms provide adaptive speed and extraction dynamics

• Discrete input time-stamp with 1 ms resolution, Analog input time stamp with 5 ms resolution

• Extensive fault detection and annunciation, including first-out indication

• Auto start sequence (hot & cold starts)

• Three sensors can be configured for each critical parameter

• Dual speed/load dynamics

• Zero speed detection with proximity probe down to 0.5 Hz

• Automatic hand valve operation (using first stage pressure)

• Remote analog setpoints for all PIDs

Connectivity / Security Features

• Independent Modbus® * communication links

• RemoteView software for any Windows 17” (43 cm) touchscreen engineering workstation for configuration, service, and turbine operation.

• Multi-lingual interface (English, Chinese, Portuguese, Japanese, Spanish and Russian).

• User level management with secure password authentication

• Achilles Cybersecurity certification

Options

• 2 Channel Actuator Modules (use for proportional or integrating actuators)

• Distributed SPC (servo position control) modules on CANOpen

• RemoteView touchscreen HMI/Workstation

• Additional RemoteView licenses for multiple workstations

• ITCC integrated compressor control (Woodward quote)

• Control cabinet (Woodward quote)

Control Specifications

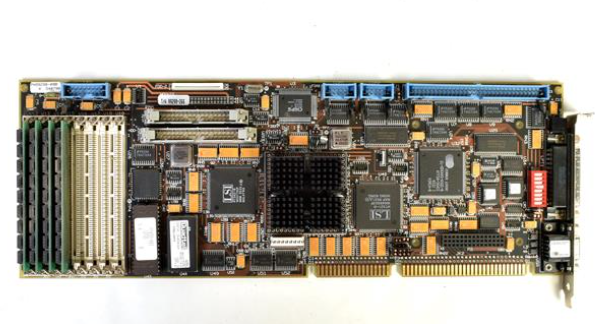

Inputs

Power: Redundant power supplies with the following input options: 18–32 Vdc, 100–150 Vdc, 88–132 Vac (47–63 Hz), 180–264 Vac (47–63 Hz), 200–300 Vdc Speed: 4 MPUs (1–30 Vrms) or proximity probes (24 Vdc and 12 Vdc power provided), 0.5 to 25 kHz

Discrete Inputs: 24 contact inputs 24 V (CE or UL) or 125 Vdc (UL only) (1 dedicated, 23 programmable)

Analog Inputs: 8 programmable 4–20 mA inputs (32 inputs with compressor control option)

Outputs

Valve/Actuator Drivers: 2 single-coil (proportional) or 2 dual-coil actuator outputs (4–20 mA)

Optional—2 proportional 20-160 mA or integrating ±200 mA max actuator outputs with

2 LVDT or RVDT or 1–5 V or 4–20 mA position feedback inputs

Discrete Outputs: 12 relay outputs with latent fault detection (1 dedicated, 11 programmable)

Analog Outputs: 4 programmable 4–20 mA outputs (12 outputs with compressor control option)

Communication

Ethernet: 6 10/100BaseT Ports (Modbus TCP or UDP & Service Tool communication)

Serial: 3 Modbus (ASCII or RTU) communication ports (RS-232, RS-422, RS-485 compatible)

Operating Conditions

Temperature: 0° - 55˚ C (32° - 131˚ F) ambient air temperature

Emissions: EN61000-6-4

Immunity: EN61000-6-2

Regulatory Compliance

(Listings are limited only to those units bearing the appropriate Marking or Agency Identification)

European Compliance EMC Directive: 2014/30/EU

for CE Marking:Low Voltage Directive: 2014/35/EU

North American CSA Certified for Ordinary Locations in the United States and Canada per

Compliance:CSA Certificate 2291171

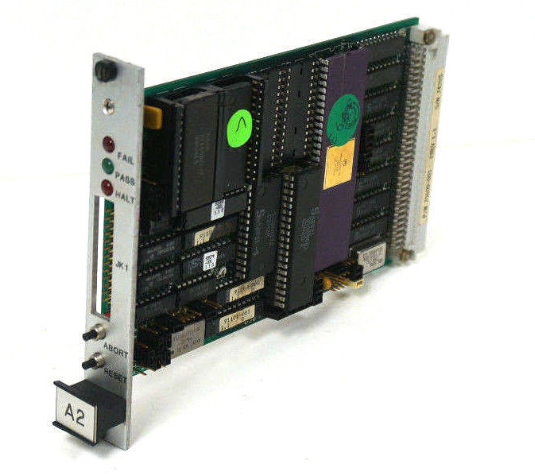

5009XT Chassis

Bulkhead or Adaptable to 19” (483 mm) rack-mount back panel with 18 slots

Approximate dimensions:

Control Chassis: 19” wide x 14” high x 12” deep (483 mm wide x 356 mm high x 305 mm deep)

Power Chassis: 7” wide x 14” high x 12” deep (178 mm wide x 356 mm high x 305 mm deep)

Approximate Weight: 56 lb (25 kg) fully loaded

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- XYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Industry News

- XP POWER

Email:wang@kongjiangauto.com