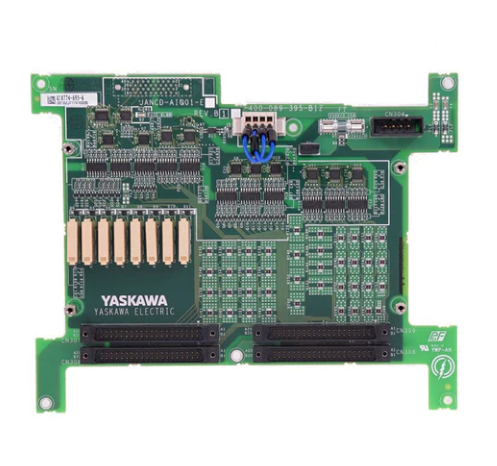

The YASKAWA JANCD-XIO01 high-performance PC input/output (I/O) board is a core interface module specially designed by Yaskawa Electric for industrial automation control systems. It is mainly used to achieve signal interaction between PCs and various actuators and sensors in industrial sites, and is a key bridge connecting upper control units and lower level actuators. This board, with its high response speed, stable signal transmission performance, and flexible adaptability, is widely used in scenarios such as Yaskawa robot control cabinets and automated production line control systems, providing reliable I/O signal processing support for precise control and efficient operation of industrial equipment. As an important member of the Yaskawa Industrial Control Module series, it adopts industry-leading technologies in circuit integration, anti-interference design, installation compatibility, etc., which can accurately match the complex signal interaction requirements of industrial sites, ensuring the stability and reliability of control systems.

YASKAWA JANCD-XIO01 High Performance PC Input/Output (I/O) Board

Core technical parameters

-Power supply parameters: The rated working voltage is DC24V, and the allowable voltage fluctuation range is ± 10%, which can adapt to the standard DC power supply environment in industrial sites; The rated working current is 1.5A, and the peak current can reach 3A (short-term overload). It can provide stable power support for various functional modules and external sensors of the board, avoiding signal loss or false triggering caused by unstable power supply.

-Signal interface parameters: The number of digital input channels is 32, supporting adaptive NPN/PNP input types. The input signal voltage range is DC12-24V, and the input response time is ≤ 1ms, which can quickly capture the status changes of on-site sensors; The number of digital output channels is 16, using transistor output mode, with a maximum output current of 0.5A per channel. It supports direct driving of small relays, solenoid valves and other actuators without the need for additional amplification circuits.

-Physical and environmental parameters: The product size specification is 160mm × 100mm × 25mm (length × width × height), adopting a compact PCB board design, suitable for standard industrial control cabinet rail installation, which can effectively save installation space and facilitate coordinated layout with other control modules; The working environment temperature range is 0-55 ℃, with a relative humidity of ≤ 90% (no condensation), and has good environmental adaptability. At the same time, the board is treated with a fully sealed coating, which has certain dust and corrosion resistance, and can operate stably in industrial environments with high dust and slightly corrosive gases.

Key functions and core features

The YASKAWA JANCD-XIO01 I/O board is equipped with advanced signal processing technology and rich functional modules, with core advantages concentrated in four dimensions: signal transmission accuracy, anti-interference ability, adaptability flexibility, and security protection:

1. High precision signal processing and fast response

By using high-speed signal acquisition and processing chips, precise capture and transmission of input and output signals can be achieved. The digital input response time is ≤ 1ms, and the digital output delay is ≤ 0.5ms. It can quickly respond to control instructions from the upper PC and status feedback from on-site devices, ensuring the real-time performance of the control system. For common weak signals in industrial sites, the board has built-in signal amplification and shaping circuits, which can effectively improve signal recognition accuracy and avoid control errors caused by signal attenuation. At the same time, the board supports signal filtering function, which can adjust the filtering time constant (0.1-10ms adjustable) through parameter settings, accurately filtering the signal noise caused by on-site electromagnetic interference, and ensuring the stability of signal transmission.

2. Strong anti-interference and stable operation guarantee

Multiple anti-interference techniques are adopted in the circuit design, and both input and output channels are equipped with optoelectronic isolation modules with an isolation voltage of ≥ 2500VAC, which can effectively isolate the impact of high-voltage signals and electromagnetic interference on the core circuit of the board, avoiding signal crosstalk and board damage. At the same time, the power interface of the board is equipped with anti surge and overvoltage protection circuits, which can resist voltage fluctuations and surge impacts in the industrial power grid, ensuring stable power supply to the board. In addition, the board adopts high-quality electronic components and rigorous PCB wiring design, which further enhances the anti-interference ability and operational stability of the circuit, and can operate stably for a long time in strong electromagnetic environments such as frequency converters and welding machines in industrial sites.

3. Flexible adaptation and expansion functions

It has good compatibility and can directly adapt to Yaskawa YRC1000, DX100 and other series of robot control cabinets and various industrial PC control systems. It seamlessly connects with the upper PC through standard PCI interface without the need for additional adaptation modules. The board supports adaptation to multiple signal types, and the digital input channel can adapt to NPN/PNP sensor signals without the need for manual switching of dip switches, greatly improving installation and debugging efficiency. At the same time, the board reserves expansion interfaces, which can increase the number of input and output channels through expansion modules (up to 64 inputs and 32 outputs), flexibly adapting to the needs of automation control systems of different scales. In addition, the board supports mainstream industrial communication protocols such as Modbus and EtherNet/IP, making it easy to achieve multi module networking control and remote monitoring.

4. Comprehensive security protection and status monitoring functions

To ensure the safety of the control system and on-site equipment, the board is equipped with multiple protection mechanisms, including overcurrent protection, overvoltage protection, short circuit protection, overheating protection, and other types. When a short circuit or overcurrent fault occurs in the output channel, the board will immediately cut off the corresponding channel output and issue an alarm signal; When the temperature of the core circuit of the board exceeds 65 ℃, the overheat protection will be automatically activated, and the board operation will be paused to avoid component damage. In addition, the board is equipped with status indicator LED lights, and each input and output channel corresponds to an independent status indicator light, which can display the working status of the channel in real time (normal, faulty, not triggered). At the same time, the board feedbacks its own working status and fault information to the upper PC through the communication interface, making it easy for operators to quickly troubleshoot faults.

Applicable industries and typical application scenarios

With high-precision signal processing capabilities, stable operating performance, and good adaptability, YASKAWA JANCD-XIO01 I/O board is widely used in multiple industrial automation fields, especially in scenarios that require high real-time and stability of signal interaction. Typical applications include:

-In the field of robot control, it is suitable for industrial robot control cabinets such as Yaskawa SP210, SP225, DX100, etc. As the core module of the I/O substrate, it realizes signal interaction between robots and surrounding fixtures, sensors, conveyor lines and other equipment, ensuring that robots accurately complete assembly, handling, welding and other operation processes. For example, in the arc welding robot workstation, the welding gun position sensor signal and workpiece clamping detection signal are collected through the board, and the welding power supply start stop and fixture opening and closing actions are controlled simultaneously to achieve automated control of the welding process.

-In the field of automated production line control, it is applied in the control system of automated production lines such as automotive parts production lines, electronic component assembly lines, food packaging production lines, etc., to achieve signal interaction between PCs and various sensors (photoelectric sensors, proximity switches, pressure sensors) and actuators (solenoid valves, servo drives, conveyor motors) on site, ensuring the coordinated and efficient operation of various processes in the production line.

-In the field of CNC machine tool auxiliary control: used for the auxiliary control system of CNC machine tools, it realizes the control of auxiliary equipment such as tool magazine, fixtures, cooling system, lubrication system, etc. By collecting the status signals of each auxiliary equipment, it feedbacks the equipment operation status to the upper PC, and executes the control instructions issued by the PC to ensure the smooth progress of the CNC machine tool processing process.

-Other industrial control scenarios: It can also be adapted to industrial control scenarios such as intelligent warehousing systems, intelligent detection equipment, and new energy equipment, providing reliable I/O interface support for signal interaction of various devices, and helping to achieve automation and intelligent control of equipment.

Installation and commissioning specifications

Proper installation and debugging are key to ensuring optimal performance of the YASKAWA JANCD-XIO01 I/O board. The following specifications must be strictly followed, while also complying with the manual requirements of the Yaskawa robot or corresponding control system:

1. Preparation before installation

Before installation, it is necessary to verify whether the board model, specifications, and control system match, check the appearance of the board for any damage during transportation (such as PCB board cracking, component detachment, pin bending, etc.), and confirm that the installation tools (such as screwdrivers, wire clamps, multimeters, anti-static hand rings) and materials (such as shielded cables, wiring terminals, insulation tape) are complete. At the same time, ensure that the installation environment meets the requirements: the ambient temperature range is 0-55 ℃, the relative humidity is ≤ 90% (no condensation), avoid installing in positions with direct sunlight, high dust, corrosive gases, strong electromagnetic interference, and severe vibration, and reserve sufficient heat dissipation space in the installation area to prevent heat accumulation from affecting the performance of the board.

2. Hardware installation and wiring

When installing, it is necessary to wear an anti-static wristband first to avoid static electricity damaging the board components. Insert the board smoothly into the standard PCI slot or dedicated mounting rail of the control system, ensuring that the board is firmly in contact with the slot and installed smoothly without looseness. The wiring process must strictly follow the wiring diagram in the product manual, and the core wiring points include:

-Power wiring: Connect the positive and negative poles of the DC24V power supply to the power interface of the board according to the nameplate identification, ensuring correct polarity; The power circuit needs to be connected to a fuse that meets the specifications (recommended 2A) to prevent overcurrent damage to the board.

-Input/output signal wiring: The input signal cable uses twisted pair shielded wires to connect the sensor signal output end to the corresponding input channel of the board. The shielding layer is grounded at one end (near the board end) to reduce electromagnetic interference; Select the appropriate wire diameter for the output signal cable according to the load type, connect the actuator to the corresponding output channel of the board, ensure that the wiring is firm, and avoid loose connections that may cause poor contact or short circuits. Attention should be paid when wiring, and input/output cables should be kept at a distance of ≥ 15cm from strong electrical lines (such as power lines) to avoid signal interference.

-Communication and grounding wire connection: Connect the board to the upper PC or controller through standard communication cables to ensure a secure communication interface connection; The grounding wire should be a cable with a cross-sectional area of ≥ 2.5mm ² and a grounding resistance of ≤ 4 Ω. Good grounding can effectively suppress electromagnetic interference and ensure stable operation of the board and personnel safety.

Special attention should be paid: all power sources must be cut off during the wiring process, and it is strictly prohibited to plug and unplug boards and wires with power on. Operators must wear personal protective equipment such as insulated gloves to avoid electric shock or static electricity damage to equipment; After the wiring is completed, it is necessary to double check the polarity and channel number of the wiring to ensure that there are no incorrect or reversed connections.

3. Debugging process and parameter settings

Debugging should follow the process of "hardware inspection software configuration signal testing system integration debugging". It is recommended to use Yaskawa official matching debugging software (such as SigmaWin+or corresponding robot control system debugging software) for parameter configuration and testing:

-Hardware status check: After connecting the power supply, observe the power indicator light of the board and the status indicator lights of each channel to confirm that the power indicator light is always on (normal) and the fault free indicator light is on; If a fault alarm occurs, immediately cut off the power and check the power wiring and board installation.

-Software parameter configuration: Connect the software to the board and set core parameters according to the control system requirements, including input signal type (NPN/PNP), filtering time constant, output channel protection mode, communication protocol parameters, etc; After the parameter settings are completed, they need to be saved to the non-volatile memory of the board to prevent power loss.

-Single channel signal testing: Conduct separate tests on each input and output channel. Input channel testing: By triggering the corresponding sensor, observe the signal status displayed by the debugging software and the board input indicator light to confirm that the signal can be accurately collected; Output channel test: Issue output instructions through software, observe the actuator action and board output indicator lights, and confirm that the output signal is normal.

-System integration debugging: Connect the board to the entire control system for full process integration debugging, simulate actual working conditions on site, check whether the signal interaction between the board and the upper PC and on-site equipment is smooth, whether the execution of control instructions is accurate, and whether there is no signal delay, loss or false triggering situation; Based on the joint debugging results, fine tune relevant parameters and optimize system performance.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-