8446-1019 is a single cylinder/single point injection control module mainly used to control spark ignition gas engines. It integrates core functions such as fuel control (air-fuel ratio), ignition timing control, sequential ignition, engine protection, and safe shutdown into a compact module. It is the brain that enables modern gas engines to operate efficiently, cleanly, and reliably.

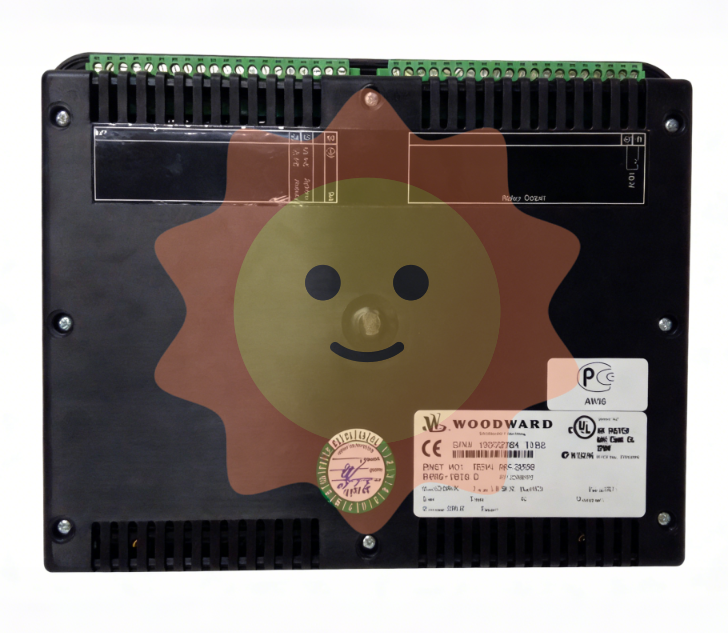

WOODWARD 8446-1019 Integrated Gas Engine Electronic Control System

core positioning

8446-1019 is a single cylinder/single point injection control module mainly used to control spark ignition gas engines. It integrates core functions such as fuel control (air-fuel ratio), ignition timing control, sequential ignition, engine protection, and safe shutdown into a compact module. It is the brain that enables modern gas engines to operate efficiently, cleanly, and reliably.

Main features and functions

Multi functional and highly integrated

Fuel metering control: Accurately controlling the on-time of gas injection valves to achieve optimal air-fuel ratio, which is crucial for emissions, efficiency, and shock prevention.

Ignition timing control: Based on engine speed, load, and operating conditions, dynamically calculate and output accurate ignition timing to optimize performance and thermal efficiency.

Sequential ignition and injection: Equipped with a built-in camshaft/phase sensor interface, it can achieve sequential ignition and fuel injection synchronized with the engine phase.

Advanced control strategy

Closed loop control of air-fuel ratio: By integrating feedback signals from oxygen sensors (such as UEGO), the fuel quantity is adjusted in real time to strictly control the air-fuel ratio at the set value (usually around the theoretical air-fuel ratio), ensuring low emissions and stable combustion.

Ignition advance angle MAP control: Based on a pre stored three-dimensional control MAP map (speed vs. load), it provides the optimal ignition timing.

Explosion proof vibration control: Monitoring through detonation sensors, automatically delaying ignition when detonation is detected to protect the engine.

Powerful input/output capability

Rich input interface:

Crankshaft speed sensor, camshaft phase sensor.

Various analog sensors such as intake pressure/temperature, gas pressure/temperature, coolant temperature, oxygen sensor, etc.

Knock sensor.

Digital input (start, stop, load switch, etc.).

Powerful output driver:

Directly drive the gas injection valve (usually a high-speed solenoid valve).

Directly drive the ignition coil (usually an intelligent ignition coil, the module outputs the ignition signal).

Multiple relay outputs are used to control the starting motor, gas shut-off valve, alarm indicator lights, etc.

Comprehensive protection and diagnosis

Programmable protection logic: Users can set multiple protections such as overspeed, overtemperature, misfire, detonation, sensor failure, etc., and provide graded alarms, load shedding, or shutdown.

Complete diagnostic tool: through Toolkit ™ The software can monitor all operating parameters in real-time, record data, view fault history, and perform system calibration.

Typical application scenarios

8446-1019 is designed specifically for gas engines that use throttle premixed or single point injection, and is widely used in:

Gas generator set (using natural gas, biogas, landfill gas, associated gas, etc.).

Gas compressor drive.

Pump drive.

Other industrial fixed spark ignition gas engines.

Product advantages

System simplification: One module replaces multiple independent controllers, reducing the number of components, wiring complexity, and fault points.

Performance optimization: The integrated collaborative control of fuel and ignition can achieve better emissions, efficiency, and responsiveness.

High reliability: Industrial grade design, integration of all key functions, and more reliable internal communication.

Easy debugging and maintenance: All parameters are set and diagnosed through a unified software (Toolkit), supporting online calibration and data recording.

Matching and compatibility

Core control objects: gas injection valve, ignition coil.

Essential sensors: crankshaft/camshaft speed sensor, intake manifold absolute pressure/temperature sensor, oxygen sensor (for closed-loop control), etc.

Configuration software: Woodward Toolkit must be used ™ Software is used for system configuration, calibration, and diagnosis.

Network communication: It usually supports CAN (SAE J1939) protocol and can communicate with generator set controllers, remote monitoring systems, etc.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-