WOODWARD 9907-147 belongs to the ProTech 203 series and is a power-off trip overspeed protection system designed specifically for rotating machinery such as steam turbines and generators. Its core function is to prevent catastrophic failures caused by overspeed operation of equipment, and it has key applications in multiple industrial fields such as power generation and petrochemicals.

WOODWARD 9907-147 Power outage tripping overspeed protection system

WOODWARD 9907-147 belongs to the ProTech 203 series and is a power-off trip overspeed protection system designed specifically for rotating machinery such as steam turbines and generators. Its core function is to prevent catastrophic failures caused by overspeed operation of equipment, and it has key applications in multiple industrial fields such as power generation and petrochemicals. The following is its detailed information:

Core technical parameters

Specific indicators for parameter categories

The power supply parameters belong to the power-off trip type, with an input voltage of 24VDC, a voltage adaptation range of 18-32VDC, and a power consumption of 5.12W

The speed related speed monitoring range corresponds to a frequency of 100Hz-32kHz and is suitable for speeds ranging from 100rpm to 20000rpm; The frequency range of the overspeed trip point is 250Hz-25kHz, with a detection accuracy of ± (0.05% x trip point frequency+2Hz)

The structural dimensions are 482.6mm wide, 310.4mm high, and 142.7mm deep, with a weight not exceeding 17 pounds

The overall working temperature for environmental adaptation is -25 ° C-60 ° C, and the working temperature for display screens is -15 ° C-60 ° C, which can cope with most harsh industrial environments

Response and output response time less than 20 milliseconds, equipped with 2 solid-state fuel trip outputs (rated 30VDC/2A) and 3 C-type contact alarm outputs (rated 30VDC/5A)

Core performance characteristics

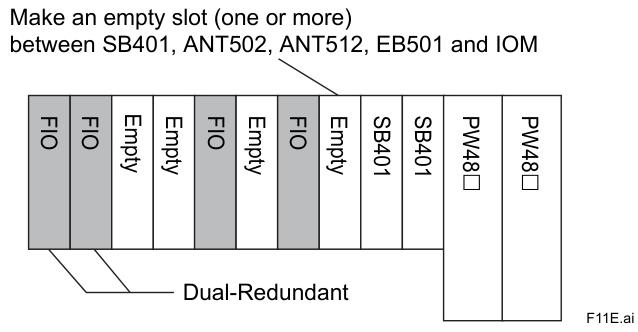

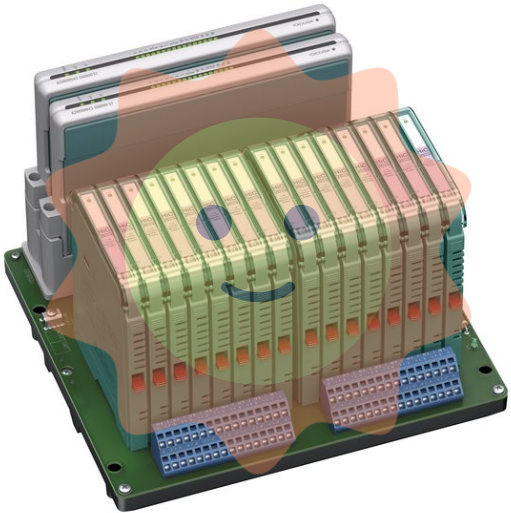

Triple redundant security guarantee: The equipment is equipped with three independent speed detection units, using a "two out of three voting" logic. Only when at least two units simultaneously detect equipment overspeed, will the trip action be triggered. This design can effectively avoid false shutdown caused by a single detection unit failure. At the same time, each of the three detection units is equipped with an independent power supply, further improving the reliability of system operation.

Convenient operation and safety protection: Equipped with 3 LCD screens, each screen displays two lines of 16 characters, making it convenient for staff to view the operation data of different units; There is also a key switch that can prevent unauthorized personnel from tampering with parameters or conducting testing operations. Moreover, the lockable design of its casing further enhances the safety of the device's use.

Complete fault diagnosis and recording: Through independent alarm output interfaces and LED indicator lights, the fault situation of a certain speed detection unit can be intuitively displayed; At the same time, it can record the peak speed during the operation of the equipment, which can provide key basis for later equipment troubleshooting and cause analysis, and help quickly locate problems.

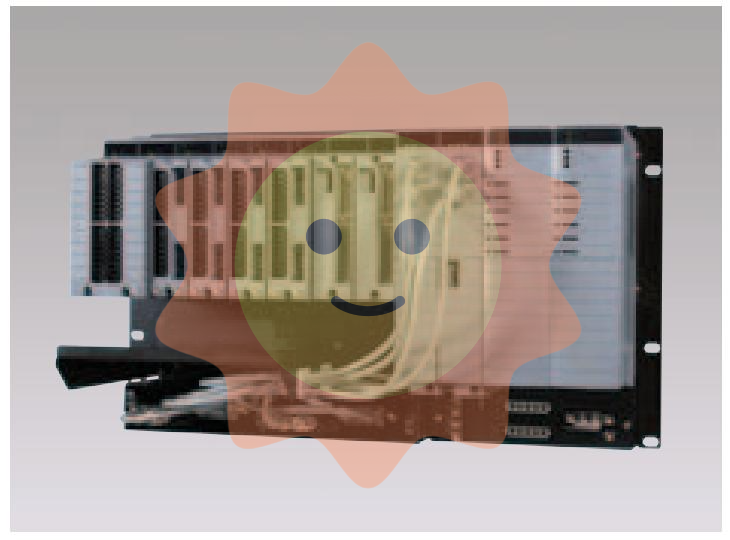

Maintenance and installation friendly: supports online hot swappable unit replacement, allowing maintenance work to be completed without downtime, significantly reducing equipment downtime; The overall design is compact, and external wiring uses connectors. When replacing modules in the future, there is no need to rewire, and the installation and replacement process is simple and efficient.

working principle

The device collects real-time speed signals of rotating machinery through three independent magneto resistive speed sensors, and the three speed detection units synchronously analyze and calculate the collected signals. During normal operation, the system continuously monitors whether the speed is within the set range; Once the speed approaches or reaches the preset overspeed trip value and meets the "two out of three" voting condition, the system will quickly output a trip signal within 20 milliseconds, cutting off fuel supply or closing key actuators such as the main steam valve, forcing the equipment to shut down; If a fault occurs in one of the detection units, it will be immediately alerted through alarm output and indicator lights, without affecting the normal monitoring work of the other two units.

Typical application scenarios

Power generation industry: commonly used for protecting steam turbines and generators in thermal and waste heat power plants, which can cope with sudden loss of load, governor failure and other emergencies leading to overspeed, avoiding damage to power generation equipment and causing large-scale power outages.

In the field of petrochemicals, it is suitable for large compressors, centrifugal fans, and other equipment in petroleum refining and natural gas transportation. Once the speed of these devices loses control, it may cause accidents such as medium leakage and equipment explosion. This device can build a strong safety line for their stable operation.

General industrial manufacturing: It can also be used for rotating machinery such as blowers and centrifuges in industries such as metallurgy and papermaking. Based on the speed requirements of different equipment, personalized trip thresholds can be programmed to adapt to diverse industrial production scenarios.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com