YASKAWA CACR-02-TE1K is a high-performance AC servo drive developed and produced by Yaskawa Electric Corporation. It belongs to the Yaskawa Sigma series (some data shows it belongs to the Sigma-V or Sigma-7 series) and is the core control component in industrial servo systems. This driver is specially designed for industrial automation scenarios. Its core function is to receive control instructions from upper computers (such as PLCs and controllers), convert them into precise electrical signals to drive AC servo motors, and collect real-time motor feedback signals (such as position and speed signals). Through closed-loop control, high-precision adjustment of motor speed, position, and torque is achieved. With its high responsiveness, high reliability, and rich functional characteristics, it is widely adaptable to various industrial equipment that require high precision in motion control, and is one of the key core components for achieving precise motion control in automated production processes. The product is originally from Japan and has international certifications such as CE, UL, and cUL, which can meet market access requirements in multiple regions around the world.

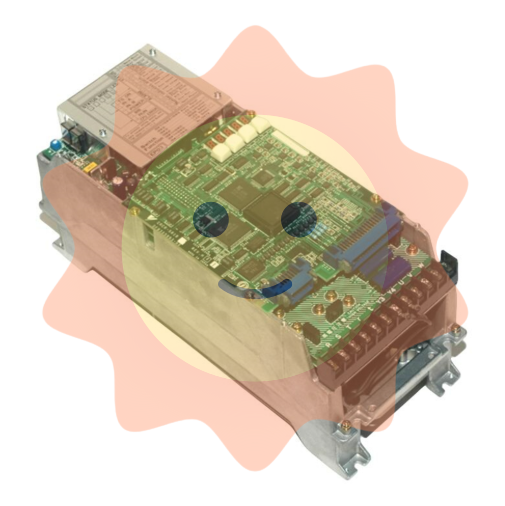

YASKAWA CACR-02-TE1K servo driver

Product Overview

YASKAWA CACR-02-TE1K is a high-performance AC servo drive developed and produced by Yaskawa Electric Corporation. It belongs to the Yaskawa Sigma series (some data shows it belongs to the Sigma-V or Sigma-7 series) and is the core control component in industrial servo systems. This driver is specially designed for industrial automation scenarios. Its core function is to receive control instructions from upper computers (such as PLCs and controllers), convert them into precise electrical signals to drive AC servo motors, and collect real-time motor feedback signals (such as position and speed signals). Through closed-loop control, high-precision adjustment of motor speed, position, and torque is achieved. With its high responsiveness, high reliability, and rich functional characteristics, it is widely adaptable to various industrial equipment that require high precision in motion control, and is one of the key core components for achieving precise motion control in automated production processes. The product is originally from Japan and has international certifications such as CE, UL, and cUL, which can meet market access requirements in multiple regions around the world.

Core functions

(1) Multi mode precise motion control

As a core function, the driver supports three mainstream working modes: position control, speed control, and torque control, which can be flexibly switched according to the needs of different application scenarios. In position control mode, it can accurately control the servo motor to reach the designated position according to the preset trajectory, with high positioning accuracy; The speed control mode can achieve constant or variable speed operation of the motor, with a wide range of speed adjustment and strong stability; The torque control mode can accurately control the output torque of the motor, suitable for scenarios that require constant tension control (such as textiles, printing, etc.). Through advanced control algorithms, the driver can achieve fast response and smooth motion, effectively reducing vibration and impact during motor operation, ensuring the stability and machining accuracy of equipment operation.

(2) Complete system protection function

The driver is equipped with a comprehensive protection mechanism that can monitor and respond quickly to various abnormal operating conditions during operation, maximizing the protection of the driver, servo motor, and the entire servo system from damage. Specific protection functions include overcurrent protection, overheating protection, overvoltage protection, undervoltage protection, encoder fault protection, etc. Some models also support safety functions that comply with the IEC 61508 standard (SIL2/SIL3 certification). When the system experiences faults such as overload, abnormal power supply voltage, or loss of encoder signal, the driver will immediately trigger the protection mechanism and shut down, while providing clear guidance for fault diagnosis through alarm codes or indicator lights.

(3) Multi protocol communication and interaction capability

The CACR-02-TE1K servo drive is equipped with rich communication interfaces, supports multiple mainstream industrial communication protocols, and has strong interconnection capabilities. Standard configuration includes interfaces such as RS-232, RS-485, CAN, etc. Some configurations include expandable Ethernet modules to achieve high-speed data exchange with upper computer, PLC, HMI (human-machine interface) and other industrial control equipment. Supporting communication protocols such as CANopen, data sharing with various industrial network devices can be achieved through protocols such as Modbus. At the same time, it can adapt to Yaskawa's dedicated communication protocols and seamlessly collaborate with Yaskawa series PLCs and controllers to ensure smooth information flow and synchronous operation of the entire automation system.

(4) Flexible interface expansion and adaptation

The driver is equipped with multiple digital input/output interfaces, which can directly connect peripheral devices such as sensors, limit switches, relays, etc., to achieve real-time monitoring and auxiliary control of the device's operating status. Simultaneously supporting incremental and absolute encoder interfaces, the encoder resolution can reach up to 24 bits, accurately collecting feedback signals of motor operation position and speed, providing reliable data support for closed-loop control. In addition, the drive supports connecting various expansion modules such as I/O modules, which can flexibly expand functions according to system requirements, enhancing the flexibility and applicability of system configuration.

(5) Convenient parameter debugging and fault diagnosis

The driver is compatible with official Yaskawa driver configuration tools (such as SigmaWin+), and the software can achieve full process operations such as parameter settings, status monitoring, and fault diagnosis. Support automatic parameter adjustment function, which can automatically optimize control parameters based on the connected motor model and load characteristics, simplify the debugging process, and reduce debugging difficulty. At the same time, the drive has a comprehensive fault diagnosis function, which can monitor the operation status of itself and the motor in real time. When a fault occurs, it can not only indicate the fault type through hardware indicator lights, but also read detailed fault codes and logs through software, helping maintenance personnel quickly locate the cause of the fault and shorten the troubleshooting time.

Detailed technical parameters

(1) Electrical core parameters

-Rated power: 250W, can accurately match Yaskawa AC servo motors of the same power level;

-Input voltage: Supports 100V-240V AC wide voltage input, single-phase/three-phase compatibility (specific model specifications need to be referred to), suitable for power supply environments in different industrial sites;

-Rated input current: 24mA (actual value can be dynamically adjusted with load changes);

-Output current: Divided into specifications such as 1A and 2A according to specific configurations, it can drive servo motors of corresponding power;

-Response frequency: Supports 1000Hz high-frequency response, can quickly respond to control instructions, suitable for high-speed precision control scenarios;

-Control method: Advanced vector control technology is adopted to improve control accuracy and dynamic response performance.

(2) Environmental adaptation parameters

-Working temperature range: 0 ℃ to+55 ℃, some models can adapt to higher temperature environments and can cope with common temperature fluctuations in industrial sites;

-Storage temperature range: -40 ℃ to+70 ℃, convenient for transportation and long-term storage in harsh environments;

-Humidity: 5% to 95% RH (non condensing), can work stably in humid environments without the need for additional moisture-proof measures;

-Protection level: IP20, needs to be installed inside the control cabinet for use, can effectively prevent solid foreign objects from entering, and protect internal components from damage;

-Vibration tolerance: Within the range of 10-500Hz, the maximum acceleration is 5m/s ² (in accordance with IEC 60068 standard);

-Impact resistance: It can withstand an impact of 15g (11ms half sine wave) and adapt to slight vibrations and impact environments in industrial sites.

(3) Physical specification parameters

-Appearance color: white/green/black (may vary depending on different batches or configurations);

-Size: Adopting a compact design, specific dimensions need to refer to the product manual. The standard DIN rail installation size is commonly used for easy installation layout;

-Installation method: Standard DIN rail installation, simple and convenient installation process, can be quickly integrated into industrial control cabinets;

-Cooling method: Natural cooling, no need to install additional heat dissipation devices, simplifies system structure and reduces energy consumption.

(4) Service life and reliability parameters

-Suggested service life: 3 years (actual service life is affected by factors such as usage environment, load conditions, maintenance, etc.);

-Mean Time Between Failures (MTBF): Meets industrial grade high reliability standards and can meet production needs for long-term continuous operation.

Key points for installation and use

(1) Hardware installation

-Installation environment: Choose a dry, ventilated, non corrosive gas, non strong vibration and impact environment, avoid direct sunlight, and strictly control the ambient temperature and humidity within the range specified by the driver; Due to the protection level of IP20, it must be installed in a closed control cabinet to prevent dust and debris from entering and affecting equipment operation;

-Installation method: Standard DIN rail installation is adopted to ensure a firm installation. Sufficient heat dissipation space should be reserved between drivers and between drivers and the inner wall of the control cabinet to avoid overheating protection caused by poor heat dissipation;

-Wiring specifications: Strictly follow the wiring requirements in the product manual, distinguish between power terminals, motor terminals, encoder terminals, and I/O interfaces, ensure that the positive and negative poles of the power supply are connected correctly, the motor winding wiring is correct, and the encoder signal circuit is firmly connected. Before wiring, all power sources must be disconnected to avoid short circuits that may damage the driver and motor;

-Grounding treatment: Make a good grounding connection for the driver, and the grounding resistance should meet the requirements (generally recommended not to exceed 4 Ω). Priority should be given to using a separate grounding method to reduce electromagnetic interference and ensure the stability and control accuracy of signal transmission.

(2) Software configuration and debugging

-Preparation of development tools: Install Yaskawa's official configuration and debugging software (such as SigmaWin+), and install the corresponding drivers and software plugins according to the driver model;

-Parameter initialization: Connect the driver through software, create a new project, select the corresponding driver model, and perform parameter initialization settings. The automatic parameter adjustment function of the software can be utilized to enable the driver to automatically identify the motor model and optimize control parameters. Key parameters such as control mode, electronic gear ratio, and limit parameters can also be manually configured according to actual application needs;

-Signal testing and calibration: Before formal operation, the input and output signals are tested through software to verify whether the signal interaction between the driver and the upper computer, sensors, and actuators is normal; Calibrate the position and speed feedback signals of the motor to ensure the accuracy of closed-loop control;

-Trial operation and debugging: After completing parameter configuration, conduct no-load trial operation to monitor the operating status of the driver and motor (such as current, temperature, vibration, etc.); Conduct a trial run with load again, fine tune the parameters according to the actual operating effect, and ensure that the equipment runs stably and the control accuracy meets the standard.

(3) Network configuration

-Basic communication configuration: According to the system communication requirements, set communication parameters (such as baud rate, address code, communication protocol type, etc.) through software or driver dip switches to ensure that the communication parameters of the driver are consistent with those of the upper computer and other control devices;

-Extended Ethernet configuration: If equipped with an Ethernet expansion module, network parameters such as the IP address, subnet mask, and gateway of the driver need to be set, and corresponding communication ports should be opened to achieve remote monitoring, parameter debugging, and data exchange;

-Protocol adaptation and debugging: If connected to industrial Ethernet networks such as Profinet, the GSD file of the driver needs to be imported into the corresponding configuration software (such as TIA Portal) to complete network configuration and signal mapping, ensuring smooth real-time data interaction with PLC or HMI.

Maintenance and upkeep suggestions

(1) Daily inspection

Develop a regular inspection plan and recommend conducting a comprehensive inspection of the drive once a week or month. The inspection includes: whether the appearance of the drive is intact, whether there is any damage, deformation, discoloration, leakage, etc; Whether the wiring terminals are loose, oxidized, or eroded, and whether the circuit connections are firm; Check for any abnormal heating, noise, or odor during the operation of the drive; Check the status of the panel indicator lights and monitor the operating parameters of the driver (such as current, voltage, temperature, etc.) within the normal range through the indicator lights and software.

(2) Cleaning and maintenance

Regularly clean the drive, removing dust, oil, and other debris from the surface and heat dissipation channels to ensure smooth heat dissipation. When cleaning, the power must be disconnected first, and a dry cloth or compressed air should be used for cleaning. It is strictly prohibited to use corrosive cleaning agents or high-pressure water guns for flushing to prevent damage to the components and housing of the drive. For the drivers inside the control cabinet, it is also necessary to regularly check whether the ventilation and heat dissipation devices of the control cabinet are working properly.

(3) Fault handling

When the drive fails, it should be stopped immediately and the power should be disconnected to avoid the fault from escalating. Based on the fault indicator status of the drive and the fault codes read by the software, combined with the fault diagnosis guide in the product manual, gradually investigate the cause of the fault. The common faults and their solutions are as follows:

-Overload fault: manifested as the overload alarm indicator light on, which may be caused by excessive load, mechanical jamming, unstable power supply voltage, improper parameter settings, etc. Solution: Check if the mechanical transmission part is smooth and eliminate any jamming phenomenon; Verify whether the load is within the rated load range of the drive; Check if the power supply voltage is stable; Re optimize the control parameters and adjust the overload protection threshold appropriately (within the allowable range);

-Overcurrent/overvoltage faults: may be caused by abnormal power supply voltage, motor winding short circuit, internal circuit faults of the driver, and other reasons. Solution: Check if the input power supply voltage meets the requirements; Disconnect the motor wiring and check the insulation and continuity of the motor winding; If the power supply and motor are normal, it may be an internal fault of the driver, and professional maintenance personnel need to be contacted for repair;

-Encoder malfunction: manifested as abnormal position feedback and motor shaking, possibly due to loose encoder wiring, poor contact, or encoder damage. Solution: Check if the encoder circuit connection is secure, unplug or replace the encoder cable; If the problem persists, check if the encoder is damaged and replace it if necessary;

-Overheating fault: often caused by poor heat dissipation, high ambient temperature, or internal cooling fan failure of the drive. Solution: Clean the dust in the heat dissipation channel of the drive; Check if the ventilation and heat dissipation device of the control cabinet is functioning properly; If the ambient temperature is too high, cooling measures should be taken; If it is an internal heat dissipation fault of the drive, it is necessary to contact maintenance personnel for handling.

(4) Software maintenance

Timely follow the official software updates and firmware upgrades released by Yaskawa, regularly upgrade debugging software and drive firmware to fix known software vulnerabilities and improve drive performance and compatibility. At the same time, regularly backup the parameter configuration files of the drive to avoid system failures caused by parameter loss or errors. It is recommended to back up the current parameters before upgrading the firmware, and ensure stable power supply during the upgrade process to avoid interrupting the upgrade process.

(5) Storage and transportation

When the drive needs to be stored or transported for a long time, it should be placed in packaging that meets the storage environment requirements, avoiding severe vibration, impact, humidity, high temperature, and corrosive environments. Before storage, all wiring must be disconnected, debris on the surface of the drive must be cleaned, and the drive must be in a power-off state. During transportation, protective and fixing measures should be taken to prevent the internal components of the driver from being damaged due to collisions and bumps. Before reusing after long-term storage, it is necessary to conduct a comprehensive inspection and parameter calibration of the drive to confirm that there are no abnormalities before putting it into use.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-