Woodward VariStroke DX hydraulic servo dual redundant sled

Woodward VariStroke DX hydraulic servo dual redundant sled

Introduction

The continuous and reliable operation of steam turbines (steam turbines) is directly related to the production efficiency and safety of factories in key fields such as power generation, petrochemicals, and industrial drives. As the core control component of a steam turbine, the reliability of valve actuators is crucial. Any unexpected shutdown can result in significant economic losses. The VariStroke DX Dual Redundant Hydraulic Servo Skid launched by Woodward is a revolutionary product designed to address this challenge. It provides unprecedented operational reliability and availability for critical API612 turbine applications through its three core functions of dual servo redundancy, online maintenance, and fast disturbance free switching.

Overview of VariStroke DX sled system

1.1 System positioning and application scenarios

The VariStroke DX sled is a complete, factory tested dual redundant hydraulic servo system package. Its main design objectives are:

Maximizing turbine operating time: Allowing maintenance or replacement of servo valves during normal operation (online) of the turbine, thereby eliminating unplanned shutdowns caused by actuator failures.

Meeting critical application standards: Designed specifically for critical steam turbine applications that comply with API 612 (7th edition) standards, it is an ideal choice for situations requiring extremely high availability.

Simplified system integration: As an independent sled type component, it integrates all necessary hydraulic, electrical, and logic control components, greatly reducing the complexity of on-site installation and commissioning.

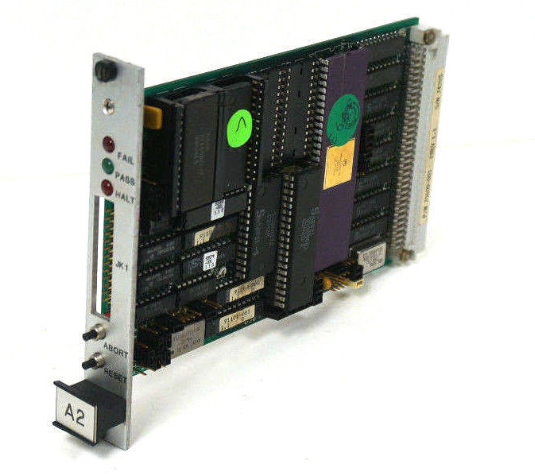

As shown in Figure 1, the VariStroke DX sled serves as the interface between the turbine control system and the VariStroke hydraulic power cylinder, receiving control commands and driving the power cylinder to precisely control the steam valve.

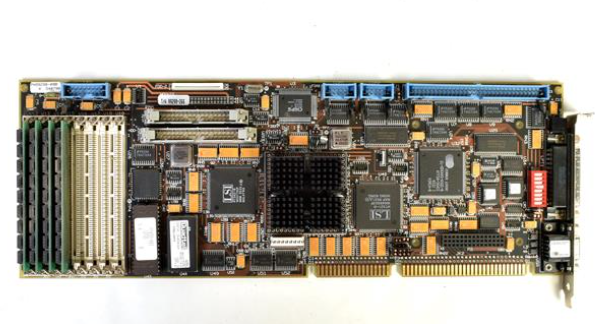

1.2 System composition and core components

The core of the sled consists of the following components:

Dual VariStroke GI servo valve: Based on Woodward's mature VariStroke GI linear electro-hydraulic actuator technology, each valve is a complete servo unit, including an electronic drive module, rotary servo valve, and internal position feedback.

Quick switching hydraulic shuttle valve: The specially designed shuttle valve is the key to achieving fast and smooth switching. It can ensure seamless transfer of control from one servo valve to another within milliseconds, while blocking the output pressure of non master servo valves to avoid system disturbances.

Integrated isolation valve and instrument:

Manual isolation valve: allows the operator to isolate any servo valve for online maintenance, replacement, or calibration without affecting another servo valve that is controlling the valve.

Large pressure gauge: It intuitively displays which servo valve is in the main control state and the output oil pressure, making it easy to monitor the status.

Electrical junction box (Zone 2 model): a terminal block that integrates all control interfaces and interconnecting lines, making it easy to connect and maintain.

Master/Slave Control Logic: The sled is equipped with intelligent logic, which can manage the cooperation of dual servo valves without external control. One of them is designated as the 'Master' unit, responsible for the actual control of valves; The other serves as a 'slave' unit that tracks the status of the master unit in real-time. Logic supports automatic switching (when the main unit fails) and manual switching (through local switches or external signals).

Core technological advantages

2.1 True online maintenance and high availability

This is the most prominent advantage of VariStroke DX. Once a traditional single servo system malfunctions, it must be shut down for maintenance. The redundant design of the DX sled allows for:

Isolate it from the hydraulic circuit through an isolation valve.

The system automatically or manually switches control to the backup servo valve without disturbance.

Disassemble, repair, replace or calibrate the isolated servo valve while the steam turbine is running continuously.

After the repair is completed, it can be put back into the system and used as a backup unit or switched back to the main control unit.

This capability transforms unplanned downtime into planned maintenance, significantly improving the overall availability of the system.

2.2 Fast and interference free switching

One of the key indicators of system performance is switching time. The indicators of VariStroke DX sled are impressive:

Manual (command) switching time: ≤ 60 milliseconds

Automatic (main unit failure) switching time: ≤ 70 milliseconds

The rapid switching is thanks to its dedicated fast shuttle valve and optimized control algorithm, ensuring that the control of the steam valve is almost unaffected, avoiding pressure fluctuations or impacts during the switching process, and ensuring the stable operation of the steam turbine.

2.3 Comprehensive signal redundancy

To match its hardware redundancy architecture, the sled also supports comprehensive redundancy in electrical interfaces, further enhancing system reliability:

Dual redundant power input: prevents single power failure.

Dual redundant 4-20 mA demand signal input: receives valve position commands from the turbine controller.

Support redundant power cylinder position feedback signal: can be connected to single redundant or dual redundant position sensors for closed-loop control.

This end-to-end redundant design constitutes a highly reliable control link.

2.4 Flexible Compatibility and Usability

Compatible with multiple power cylinders: The sled itself does not include a power cylinder. Users can choose a suitable VariStroke hydraulic power cylinder separately according to specific requirements such as force, stroke, spring recoil, etc., and remotely connect it through a pipeline of up to 10 meters. This provides great application flexibility.

Compact integrated design: All components are integrated onto one sled, reducing on-site installation of pipelines and wiring work, and lowering overall installation costs.

Clear status indication: The pressure gauge provides local visual indication, and the discrete output relay contacts can be used to connect to DCS or indicator lights for remote master/slave status and system health monitoring.

Product specifications and environmental adaptability

3.1 Physical and Environmental Specifications

Size and weight:

Zone 2 model (with junction box): approximately L629.9 x W968.2 x H724.9 mm, weighing approximately 200 kg.

Zone 1 model (without junction box): more compact, approximately L401.3 x W968.2 x H432.6 mm.

Environmental temperature: -40 ° C to+85 ° C, suitable for extreme weather conditions.

Oil temperature:+15 ° C to+70 ° C.

Installation method: Horizontal installation.

3.2 Hydraulic and Fluid Requirements

Working pressure range: 3.44 to 35 bar (50 to 500 psi), suitable for low-pressure turbine oil systems.

Fluid type: mineral oil or synthetic oil.

Oil cleanliness: Recommended ISO 4406 20/18/16 grade or higher (β ₇₅ ≥ 75).

Port standard: SAE J518 Code 61 flange.

3.3 Hazardous Area Certification

The VariStroke DX sled offers two certified models to meet installation environments with different safety requirements:

Zone 1/Class I, Div. 1 certified model: suitable for areas where explosive gas environments exist for a long time. The sled model itself does not include a junction box, and the wiring needs to be led to a Zone 1 certified junction box or non hazardous area for processing.

Zone 2/Class I, Div. 2 certified models: suitable for areas where explosive gas environments may occasionally exist. This model has integrated a Zone 2 certified junction box for easy installation.

System working principle and functional diagram

As shown in Figure 5, the system workflow is as follows:

The turbine controller sends a valve position command (4-20mA) to the sled.

The Master VariStroke GI servo valve (such as Unit "A") inside the sled controls its output oil pressure through an internal closed-loop according to instructions.

This pressure is directed through the shuttle valve to the control port (C1/C2), which in turn drives the remotely installed hydraulic power cylinder.

The power cylinder drives the steam valve to move, and its position is returned to the sled and turbine controller through feedback sensors, forming a closed loop.

Synchronously receiving the same command from the Slave servo valve (Unit "B") and causing its internal output pressure to follow the main valve, but blocked by the shuttle valve and in a hot standby state.

Once the main valve fails or its output is abnormal, the shuttle valve switches paths within milliseconds under internal logic control, and the slave valve immediately takes over control, achieving disturbance free switching.

Isolation valves S1/S2 and D1/D2 are respectively used to isolate the oil supply and return lines of the servo valve, while N1/N2 are used to isolate its control oil output.

Application Value and Summary

The Woodward VariStroke DX dual redundant hydraulic servo sled is not just a product, but a system level solution to enhance the operational reliability of critical power equipment. Its value is reflected in:

Economic benefits: By almost eliminating unplanned shutdowns caused by actuator failures, continuous process industrial users have saved hundreds or even millions of downtime losses.

Safety benefits: The built-in safety logic and automatic fault switching function reduce the risk of unit failure caused by control failure.

Maintenance benefits: The online maintenance capability has changed the maintenance mode, allowing maintenance work to be scheduled within the planned window, improving maintenance efficiency and reducing the time pressure on maintenance personnel.

Engineering benefits: Its pre integrated, pre tested sled design and built-in intelligent logic greatly simplify control system engineering and on-site installation and commissioning work, shortening project cycles.

For any application that has extreme requirements for the reliability of steam turbine operation, whether it is offshore platforms, isolated power plants, large chemical plants, or critical mechanical drives, the VariStroke DX sled represents the advanced level of hydraulic valve redundancy technology and is a strategic choice to ensure the continuous, efficient, and safe operation of core assets.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- XYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Industry News

- XP POWER

Email:wang@kongjiangauto.com