SCHNEIDER TeSys ® GV2/GV3 series motor circuit breakers

SCHNEIDER TeSys ® GV2/GV3 series motor circuit breakers

Schneider Electric: Global Leader in Energy Efficiency Management

Schneider Electric, as a global energy efficiency management expert, provides comprehensive solutions to over 100 countries and holds a leading position in areas such as energy and infrastructure, industrial process control, building automation, data centers, and residential applications. The company has always been committed to providing customers with safe, reliable, and efficient energy, with sales of 19.6 billion euros in 2010 and over 110000 employees worldwide. The core concept of "making good use of its effectiveness and fully enjoying its capabilities" runs through all products and solutions.

Since entering the Chinese market in 1987, Schneider Electric has introduced circuit breaker technology to China through its Tianjin Meilan Rilan joint venture factory, gradually promoting the improvement of China's electrical safety standards and industrialization process. At present, Schneider Electric has 77 offices, 26 factories, 6 logistics centers, 3 research and development centers, and over 700 distributors in China, with nearly 22000 employees, providing advanced product support and comprehensive technical services for the Chinese market.

Schneider Electric launches EcoStruxure ™ The energy efficiency management platform integrates its application in building construction IT、 With professional experience in five major fields including security, power, and industrial processes, we provide customers with open, transparent, energy-efficient energy management solutions through a unified architecture, helping enterprises save up to 30% of investment and operating costs.

TeSys series motor circuit breakers: a comprehensive overview of domestic and imported product lines

Schneider Electric's TeSys series motor circuit breakers are divided into two product lines: domestic and imported, covering various types of thermal magnetic and electromagnetic types, suitable for motor protection scenarios with different power, voltage, and environmental requirements.

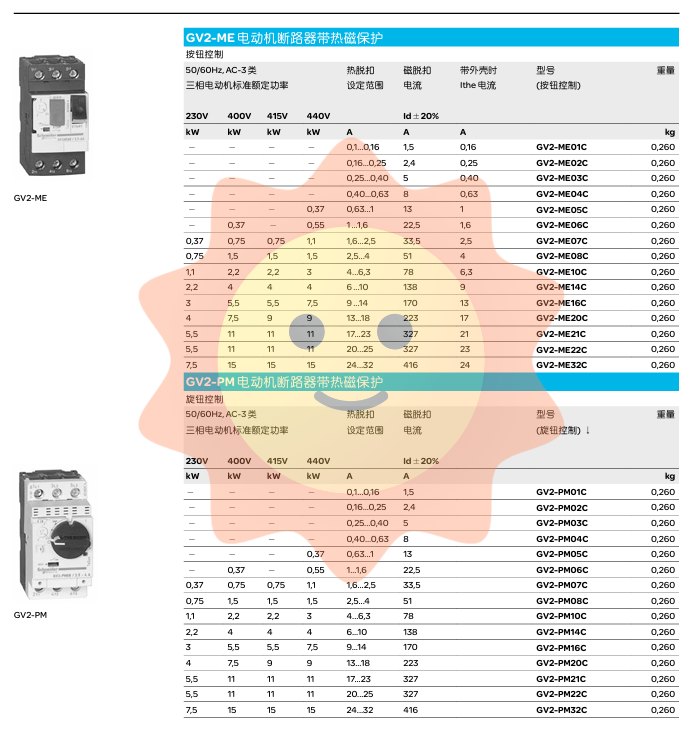

2.1 Domestic TeSys motor circuit breakers: GV2-ME and GV2-PM

The domestically produced GV2 series is a thermal magnetic motor circuit breaker suitable for AC 50/60Hz systems, with a rated current coverage of 0.1A to 32A and a maximum motor power of 15kW (400V). The product complies with various international standards such as IEC 947, EN 60204, UL 508, CSA, and has obtained CCC and CE certifications.

The core features include:

Excellent breaking capacity: Within the voltage range of 230V~690V, the maximum breaking current (Icu) can reach 100kA, especially in 400V systems with a breaking capacity of 15kA~50kA.

Thermal magnetic dual protection: The thermal element provides overload protection and has automatic compensation function for ambient temperature; Magnetic components provide short-circuit protection, with a trip threshold of 13 times the thermal set current.

Modular design: supports the installation of various accessories such as auxiliary contacts, undervoltage trip, and shunt trip, with strong scalability.

Flexible installation: Can be installed on 35mm standard rails, panels, or porous mounting plates, supporting vertical or horizontal installation.

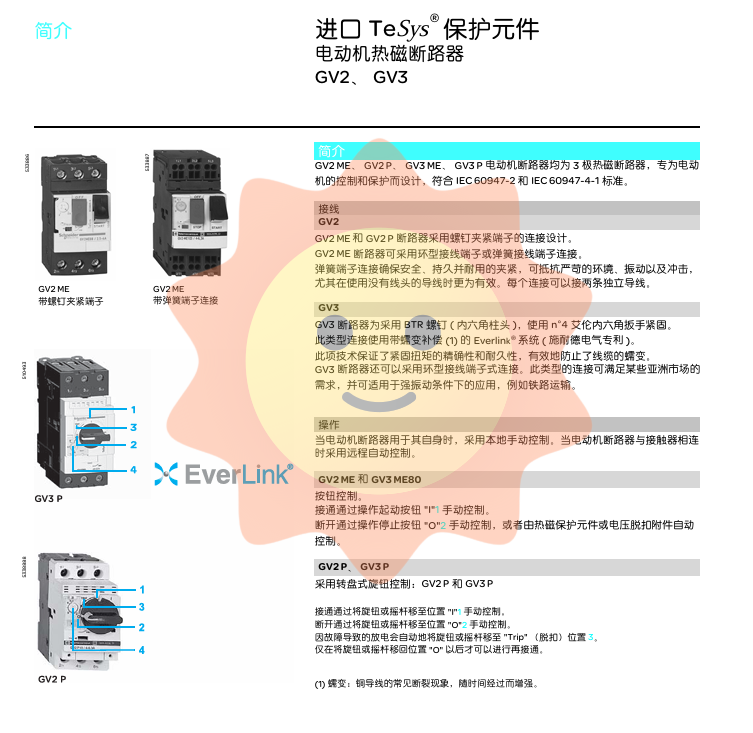

2.2 Imported TeSys motor circuit breakers: GV2/GV3 series

The imported product line is more diverse, including:

GV2ME/GV2P: Thermally magnetic, rated current up to 32A, with a maximum breaking capacity of 100kA.

GV3ME/GV3P: Thermally magnetic, current up to 80A, suitable for higher power motors (up to 37kW).

GV2LE/GV2L/GV3L: Electromagnetic type, to be used in conjunction with thermal overload relay, suitable for precise overload protection scenarios.

GV2RT: Designed for motors with high starting peak current, the magnetic trip threshold is increased to 20 times In.

Further optimization of imported products in terms of structure, wiring, and applicable environment:

There are various wiring methods: GV2ME can choose screw clamping or spring terminals; The GV3 series uses EverLink ® Screw connection system, resistant to vibration and creep.

High protection level: Some models have a protection level of IP65, suitable for harsh environments.

Complete certification: equipped with UL, CSA, CCC, GOST, ATEX (partial) and other multinational certifications.

Core technical parameters and performance analysis

3.1 Breaking ability and current limiting characteristics

The breaking capacity of an electric motor circuit breaker is the key to evaluating its protective performance. In the 400V system, the GV2/GV3 series has Icu values ranging from 10kA to 100kA, and most products have high operating breaking capacity (Ics), with some reaching 100% of Icu. When used in conjunction with current limiting modules (such as GV1-L3), it can further improve the breaking performance and limit the thermal stress of short-circuit current, protecting downstream cables and equipment.

3.2 Thermal Magnetic Release Curve and Protection Characteristics

The thermal magnetic trip curve intuitively reflects the action time of the circuit breaker under overload and short circuit conditions. The GV2/GV3 series offers a multi curve family starting from cold and hot states, ensuring that the motor does not malfunction under starting current surges and provides reliable protection in the event of sustained overload. Electromagnetic circuit breakers (GV2L/GV3L) require LRD or LR2K series thermal relays to achieve inverse time overload protection.

3.3 Electrical Release and Safety Functions

The series supports under voltage trip (UV) and shunt trip (SH) to enhance system safety. Under voltage trip can disconnect the circuit when the power supply is abnormal, preventing the motor from starting automatically when the voltage is restored; The shunt release supports remote disconnection. In addition, all operating handles can be locked in the "OFF" position with a padlock to achieve mechanical interlocking and comply with safety operation regulations.

3.4 Environmental adaptability and reliability

The working temperature range of the product covers -20 ℃ to+60 ℃ (enclosed installation up to+40 ℃), and the storage temperature is as low as -40 ℃. It has good anti vibration (5gn), anti impact (30gn) performance and flame retardant properties (960 ℃), suitable for complex environments in industrial sites. The protection level can be selected from IP20 to IP65 to meet the requirements of different installation scenarios.

Rich attachments and modular expansion

The TeSys series provides highly modular accessory systems that users can flexibly configure according to their needs

Signal contact module: including instantaneous auxiliary contacts (GV-AE/GV-AN), fault indication contacts (GV-AD), and short-circuit signal contacts (GV-AM), used for status feedback and system interlocking.

Electrical trip module: covering undervoltage and shunt trip coils with various voltages ranging from 24V to 600V.

Connection and busbar system: Provides 3-pole 63A busbar (GV2-G series), terminal block (GV2-G05), and flexible connection block for easy wiring inside the cabinet.

Operation and installation accessories: including external operating handle (padlockable), adapter board, compensation board, installation guide rail, etc., supporting cabinet door installation and remote operation.

Selection Guide and Installation Suggestions

5.1 Key steps for selection

Determine motor parameters: rated power, voltage, current, and starting characteristics.

Select circuit breaker type: Choose between thermal magnetic or electromagnetic based on protection requirements.

Check the breaking capacity: Ensure that Icu is greater than the expected short-circuit current at the installation point.

Select rated current: Select within the adjustable range of the circuit breaker based on the motor's full load current.

Confirm attachment requirements, such as signal contacts, trip coils, operating methods, etc.

Consider installation environment: temperature, humidity, protection level, vibration conditions.

5.2 Installation precautions

Ensure sufficient electrical clearance and creepage distance, and increase the spacing for high voltage (such as 690V) applications.

When multiple units are installed side by side, leave a gap of ≥ 9mm for heat dissipation or installation of side accessories.

It is recommended to use torque tools to tighten the wiring terminals to avoid being too loose or too tight.

For hazardous machinery, undervoltage trip wiring schemes that comply with INRS standards should be selected.

Application Value and Summary

Schneider Electric's TeSys series motor circuit breakers have become the preferred solution in the field of industrial motor protection due to their comprehensive product line, excellent protection performance, highly modular design, and extensive international certification. Whether it is the economic applicability of the domestically produced GV2 series or the high performance and reliability of the imported GV2/GV3 series, both can help users achieve:

Enhance system security: precise overload and short circuit protection to avoid equipment damage and accidents.

Enhance operational efficiency: Modular attachments and clear status indicators simplify maintenance and fault diagnosis.

Optimizing energy efficiency management: Combining EcoStruxure platform to achieve monitoring and optimization of energy use.

Ensure compliance: comply with multiple standards such as IEC, UL, CSA, CCC, etc., to facilitate smooth project acceptance.

Model Supplement

AS-BDEP-218

AS-HDTA-202

AS-P120-000

AS-P892-000

AS-S911-801

ATV31HU40N4A

BMXDDI1602

C65N 1P C10

C65N 1P C16

C65N 3P D63

C65ND10

GV2-RS32C

GV2-S21C

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA