Product Overview

The WOODWARD EASYGEN-3200-5 8440-1992 A is a sophisticated control solution designed for the management of generator sets in mission-critical power environments. As part of the EasyGen-3000 series, this controller is engineered to provide total system integration, combining generator set control, protection, and logic capabilities into a single, robust unit. It is specifically tailored for applications requiring complex control strategies, including multi-generator paralleling, load sharing, and synchronization with the utility grid.

This controller is capable of managing gensets of various sizes and fuel types, making it a versatile choice for industrial facilities, data centers, hospitals, and large commercial complexes. The 8440-1992 A variant ensures compliance with rigorous industry standards, offering a reliable interface between the prime mover and the electrical infrastructure. Its architecture supports both standalone operation and integration into complex Power Management Systems (PMS), providing operators with full visibility and control over their power assets.

Advanced Control Architecture

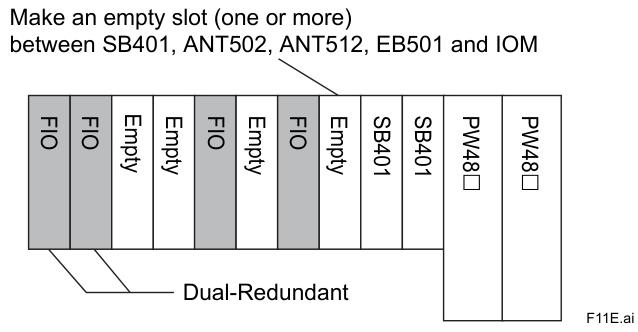

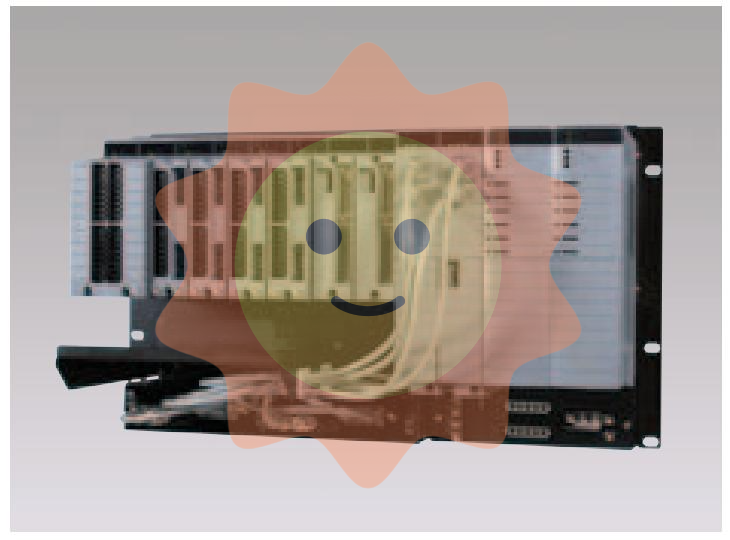

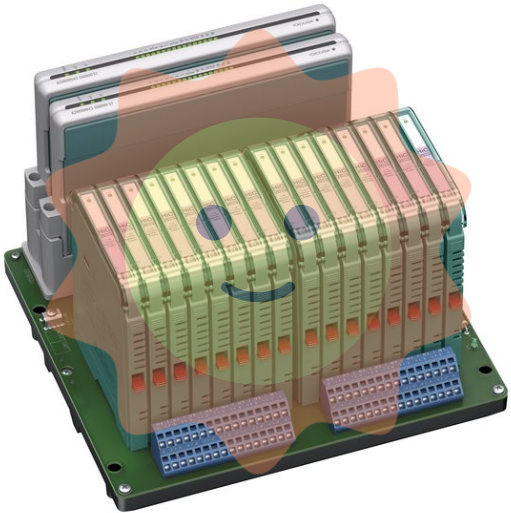

The EASYGEN-3200-5 utilizes a high-speed processor to handle real-time logic. It features a modular design that allows for seamless expansion and configuration, ensuring that the controller can adapt to specific site requirements without the need for extensive external hardware.

Paralleling and Synchronization

One of the standout features of the WOODWARD EASYGEN-3200-5 is its advanced paralleling capability. The controller manages the complex process of synchronizing a generator set to a live bus or to other generators automatically. It continuously monitors voltage, frequency, and phase angle differences, adjusting the engine speed and generator voltage via the AVR to achieve perfect synchronization conditions.

Automatic Synchronization: Calculates the precise moment to close the circuit breaker to minimize inrush currents and mechanical stress on the generator.

Load Sharing: Active kW and kVAR load sharing is managed via high-speed CAN bus or analog lines. The controller adjusts fuel and excitation to ensure each generator carries its proportional share of the total load.

Mains Return (Auto Re-close): Automatically resynchronizes the load to the utility grid when mains power is restored and is within stable parameters.

Dead Bus / Live Bus Start: Flexible logic that allows the genset to start against a dead bus (black start) or synchronize with a live bus.

Peak Shaving: Monitors the mains import/export levels and automatically starts/stops generators to reduce peak demand charges from the utility.

Comprehensive Protection Functions

Reliability is paramount in power generation, and the EASYGEN-3200-5 provides a multi-layered defense mechanism to protect both the engine and the generator. The unit includes an extensive library of protection functions that are fully programmable to match the specific ratings of the alternator and prime mover.

Electrical protection includes over/under voltage, over/under frequency, short circuit detection, reverse power, and negative sequence protection. Mechanical protection is facilitated through inputs monitoring engine oil pressure, coolant temperature, and speed. Upon detecting a fault condition, the controller can initiate an alarm or an immediate shutdown, separating the load and preventing catastrophic failure.

User Interface and Connectivity

The human-machine interface (HMI) on the EASYGEN-3200-5 consists of a high-contrast, backlit graphical LCD display. This screen provides real-time visualization of electrical parameters, alarm history, and status indicators. The navigation buttons are designed for intuitive operation, allowing operators to easily acknowledge alarms and access configuration menus.

Connectivity is a key strength of this model. It features multiple communication ports, including RS232 and RS485 for Modbus communication. This allows for seamless integration with SCADA systems and Building Management Systems (BMS). Additionally, CAN J1939 connectivity allows for direct communication with electronic engines (ECUs), eliminating the need for cumbersome sensor wiring and enabling the controller to view engine diagnostic data directly.

Technical Specifications

| Manufacturer | Woodward |

|---|---|

| Series | EasyGen 3000 Series |

| Model Number | EASYGEN-3200-5 8440-1992 A |

| Rated Voltage | 100-277 V L-N (50/60 Hz) |

| Inputs | 3 PTs, 3 CTs, 12 Digital Inputs, 6 Analog Inputs |

| Outputs | 10 Relay Outputs, 4 Transistor Outputs |

| Communication | RS232, RS485 (Modbus), CAN J1939, Ethernet (Optional) |

| Current Rating | Up to 5 A continuous |

| Operating Temperature | -20°C to +70°C |

| Mounting | Panel Mount (IP54) |

Applications

The versatility of the WOODWARD EASYGEN-3200-5 makes it suitable for a wide array of critical power applications. It is frequently deployed in data centers where continuity of power is vital for preventing data loss and downtime. In healthcare facilities, such as hospitals, the controller ensures that life-support systems remain operational during grid outages through automatic mains failure (AMF) functions.

Furthermore, this controller is ideal for industrial plants using Combined Heat and Power (CHP) systems, where efficient energy utilization is critical. Its ability to manage complex synchronization and load sharing makes it equally valuable for prime power installations in remote locations, such as mining operations or isolated island grids, ensuring stable and reliable power delivery regardless of the application's complexity.