Product Overview

The Baldor KPD-KG420-20 represents a critical component in the realm of industrial automation, serving as a bridge between complex machine processes and human operators. Specifically designed as a 4x20 character and graphic display, this unit facilitates the management of drive systems and motion control applications. Its robust design ensures it can withstand the rigors of industrial environments while providing precise, real-time feedback.

As part of the Baldor family of operator interfaces, the KPD-KG420-20 is engineered to streamline the setup and operation of compatible Baldor products. The integration of a serial interface allows for reliable communication with controllers, ensuring that data transmission remains stable even in electrically noisy settings. This module is essential for technicians and engineers who require immediate access to system parameters, status indicators, and fault diagnostics without needing to connect a laptop or external computer.

Advanced Display and Visualization

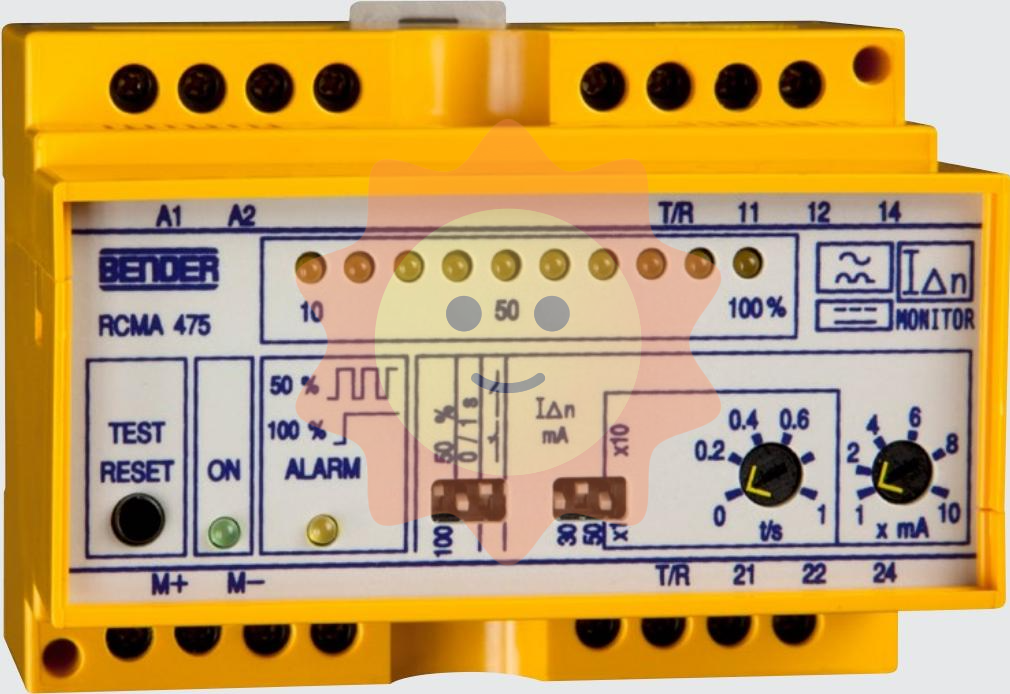

At the heart of the KPD-KG420-20 is its high-visibility 4-line by 20-character Liquid Crystal Display (LCD). Unlike standard text-only interfaces, this unit incorporates graphic capabilities, allowing it to visualize simple bar graphs and custom icons. This feature significantly enhances the user experience by providing intuitive representations of data, such as drive torque, current load, or speed setpoints.

The display is equipped with a high-contrast backlight, ensuring that information remains clearly legible under various lighting conditions, including dimly lit factory floors or areas with direct overhead lighting. This clarity is vital for reducing operator error and maintaining high productivity levels during operation and maintenance procedures.

Serial Interface and Connectivity

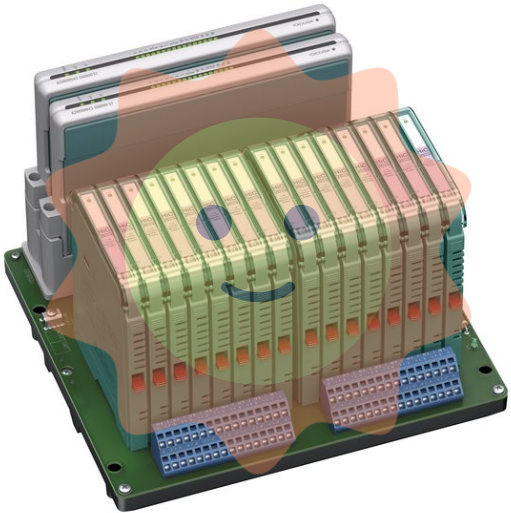

Connectivity is a defining feature of the Baldor KPD-KG420-20. The unit utilizes a standardized serial interface, typically RS-232 or RS-485 protocols depending on the system configuration, to communicate with the host drive or controller. This serial communication method is preferred in industrial applications due to its reliability over longer cable runs and its inherent resistance to interference.

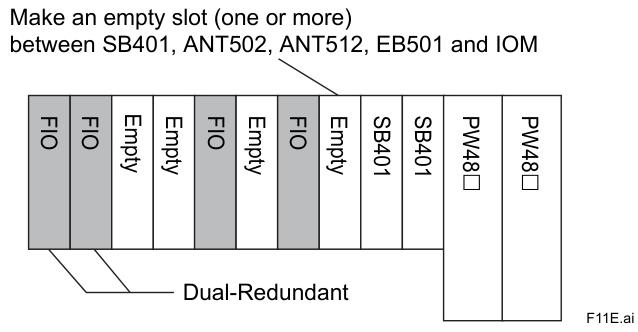

Through this interface, the keypad acts as a sophisticated remote terminal. It enables users to upload and download parameter sets, modify control logic on the fly, and monitor internal variables. The ability to daisy-chain units or integrate them into a larger network makes the KPD-KG420-20 a versatile choice for both standalone machinery and complex production lines.

Key Features and Specifications

Display Type: 4-line x 20-character LCD with graphic functionality.

Interface: Reliable Serial Port for robust data communication.

Keypad Design: Industrial-grade membrane buttons designed for frequent use and longevity.

Visualization: Support for alphanumeric text and basic graphic elements.

Compatibility: Optimized for use with Baldor drives and motion control systems.

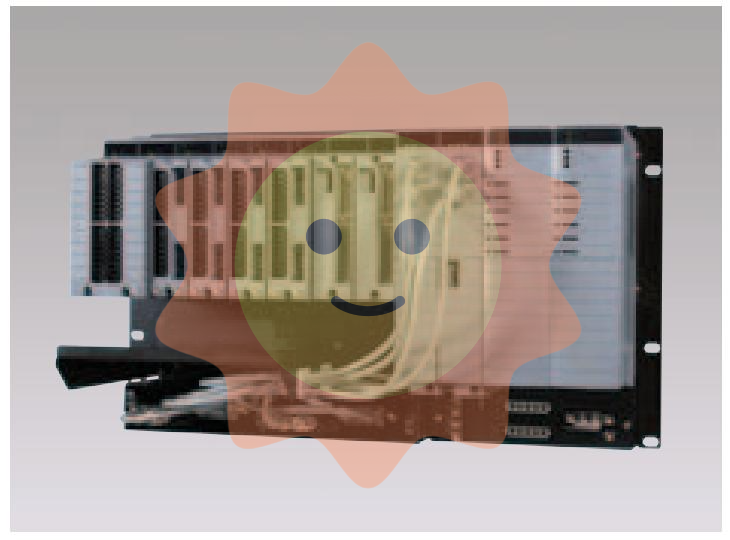

Mounting: Designed for panel-mount installation, offering a clean and secure fit into control cabinets.

Industrial Durability and Design

Durability is paramount in industrial electronics, and the Baldor KPD-KG420-20 is constructed with this principle in mind. The front panel features a sealed membrane keypad that protects the internal circuitry from dust, oil, and moisture. This ingress protection ensures that the device continues to operate accurately even in harsh environments where standard office-grade equipment would fail.

The physical layout of the keys is ergonomically designed to facilitate navigation through complex menu structures. Dedicated function keys often allow for quick access to frequently used commands, such as Start, Stop, Reset, and Menu navigation. This user-centric design reduces the learning curve for operators and minimizes the time required for training.

Applications and Integration

The Baldor KPD-KG420-20 is ideally suited for a wide array of applications, including conveyor systems, packaging machinery, textile manufacturing, and CNC machine tools. In these scenarios, the operator needs immediate control over the motor or drive parameters. By providing direct access to the Baldor controller, the KPD-KG420-20 eliminates latency associated with upper-level HMI systems, allowing for faster troubleshooting and immediate adjustments.

Furthermore, the graphic capabilities of the display allow for custom status messages. Instead of interpreting cryptic error codes, operators can read plain-text descriptions of system statuses, which enhances safety and efficiency. The module’s ability to store configuration data also aids in quick machine changeovers, making it a valuable asset in facilities with high product mix.

Conclusion

In summary, the Baldor KPD-KG420-20 4x20 Character/Graphic Display is a vital tool for industrial automation. It combines the simplicity of a text-based keypad with the enhanced visualization of graphics, all backed by a rugged industrial design and reliable serial communication. For systems utilizing Baldor technology, this interface module offers the precision, durability, and ease of use required to maintain optimal operational efficiency.