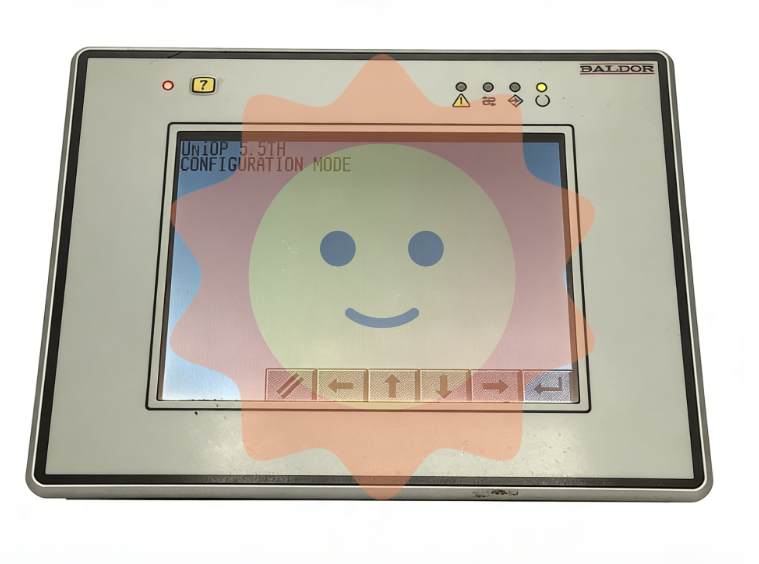

The Baldor KPD-TS05C-30E is an advanced industrial operator interface featuring a vibrant 5.6-inch color TFT touch screen display with integrated serial and Ethernet communication capabilities. Designed specifically for seamless integration with Baldor motor drives and control systems, this HMI terminal provides intuitive graphical control, real-time monitoring, and extensive diagnostic capabilities for industrial automation applications. Its dual-interface design offers flexible connectivity options suitable for both direct drive connections and networked control architectures.

Baldor KPD-TS05C-30E 5.6" Color TFT Touch Screen with Serial and Ethernet Interface

Advanced Display and Touch Interface Technology

At the core of the KPD-TS05C-30E is its vibrant 5.6-inch thin-film transistor (TFT) display, capable of rendering 65,536 colors with exceptional clarity and brightness. This high-resolution screen provides superior visualization of machine status, process variables, alarm conditions, and graphical representations of motor performance. The resistive touch screen technology ensures reliable operation even when operators are wearing gloves, with precise touch recognition that facilitates quick menu navigation and parameter adjustments.

The display interface supports comprehensive graphical elements including trends, bar graphs, animated components, and custom bitmaps, allowing system integrators to create tailored operator experiences. Unlike monochrome or character-based displays, this color TFT screen enables color-coded alarms, status indicators, and intuitive navigation schemes that reduce operator training time and minimize errors during critical operations.

Technical Specifications

Display Specifications

Screen Size: 5.6-inch diagonal TFT LCD

Resolution: 320 x 240 pixels (QVGA)

Colors: 65,536 (16-bit)

Touch Technology: Analog resistive touch

Communication Interfaces

Ethernet: 10/100 Base-T for network connectivity

Serial Interface: RS-232/RS-485 compatible

Integration: Native compatibility with Baldor drives

Protocols: Supports industrial communication standards

Physical & Environmental

Mounting: Panel-mount design

Enclosure: Industrial-grade materials

Operating Temperature: Suitable for industrial environments

Power Supply: 24V DC standard industrial power

Dual Communication Architecture

The KPD-TS05C-30E distinguishes itself with its flexible dual-interface communication system. The integrated Ethernet port (10/100 Base-T) enables seamless connectivity to local area networks, facilitating remote monitoring, data logging, and integration with supervisory control systems. This network capability allows multiple HMI units to communicate with various drives and controllers across the factory floor, centralizing control and visualization.

Simultaneously, the built-in serial interface (RS-232/RS-485) provides direct, reliable communication with individual Baldor motor drives and legacy equipment. This dual approach ensures compatibility with both modern networked architectures and traditional point-to-point control systems, offering unparalleled installation flexibility.

Key Communication Features

Simultaneous Protocol Support: Operates multiple communication protocols concurrently for diverse equipment integration.

Real-Time Data Exchange: Monitors drive parameters including speed, torque, current, temperature, and fault history.

Remote Configuration: Enables parameter upload/download and firmware updates through network connections.

Data Logging Capability: Stores operational data for performance analysis and preventive maintenance.

Industrial Applications and Implementation

The Baldor KPD-TS05C-30E is engineered for demanding environments across multiple industries. Its rugged design withstands vibration, electrical noise, and variable temperatures typical of industrial settings.

Implementation typically involves configuring custom screens using Baldor's dedicated software tools, which allow designers to create application-specific interfaces with intuitive navigation structures. The unit serves as both a configuration tool during commissioning and a daily operator interface for normal operations, displaying real-time feedback and providing touch controls for starting, stopping, jogging, and adjusting drive parameters.

Integration with Baldor Drive Systems

Specifically optimized for Baldor motor control products, the KPD-TS05C-30E offers pre-configured screen templates and parameter access for Baldor variable frequency drives, servo drives, and motion controllers. This native compatibility reduces engineering time and ensures reliable communication. Operators can access drive-specific parameters, fault diagnostics, maintenance schedules, and performance data through logically organized menus that reflect the drive's internal parameter structure.

Conclusion

The Baldor KPD-TS05C-30E Color TFT Touch Screen Interface delivers a sophisticated yet practical solution for modern industrial control visualization. By combining an intuitive color touch interface with robust serial and Ethernet connectivity, it bridges the gap between complex drive technology and operator accessibility. Its flexibility in supporting both standalone and networked configurations makes it suitable for applications ranging from single-drive installations to comprehensive multi-drive control systems. For engineers seeking to enhance operator interaction with Baldor motor controls while maintaining industrial reliability, the KPD-TS05C-30E provides a comprehensive, future-ready interface solution that improves both operational efficiency and system diagnostics.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-