Product Overview

The WOODWARD 8237-1369 is an advanced electronic governor control module designed to meet the rigorous demands of modern power generation and industrial drive applications. As a critical component within the turbine or engine management system, this module is responsible for maintaining precise rotor speed and controlling the load on the machine. By continuously comparing actual speed against a setpoint, the 8237-1369 adjusts fuel or steam flow via actuation signals to maintain optimal operational efficiency.

This control unit is engineered for versatility, supporting a wide range of prime movers including steam turbines, gas turbines, and large reciprocating engines. Its robust design ensures reliable performance in harsh industrial environments where vibration, temperature fluctuations, and electrical noise are common. The module serves as the brain of the control system, executing complex logic to ensure stability during transient load changes and providing the necessary protection mechanisms to safeguard valuable machinery.

Core Control Capabilities

The functionality of the WOODWARD 8237-1369 centers on high-speed processing and precise actuation. It utilizes advanced control algorithms to manage the dynamics of the prime mover, ensuring that speed deviations are corrected instantaneously.

Operational Features & Control Logic

The operational integrity of the 8237-1369 is defined by its ability to manage multiple control modes seamlessly. In speed control mode, the unit maintains the turbine or engine at a fixed speed regardless of the load, which is essential for applications driving generators that must synchronize with the grid. The controller automatically compensates for load disturbances, adjusting the actuator output to restore the desired frequency.

Droop Speed Control: Allows for stable load sharing between multiple units running in parallel. The speed setpoint decreases slightly as load increases, ensuring equitable distribution of the total load without hunting or oscillation.

Isochronous Speed Control: Used when a unit is operating in island mode (independent of the grid). This mode maintains constant speed regardless of load variations, ensuring stable frequency for critical electrical loads.

Load Sharing: Facilitates the synchronization of load changes across multiple prime movers, coordinating with external load sharing modules or communication networks to balance kW output.

Sequential Control: Manages the automated startup and shutdown sequences of the turbine, including warm-up periods, acceleration ramps, and cooldown phases to minimize thermal stress.

Limiting Functions: Integrated software limits protect the engine by restricting maximum fuel, speed, or actuator position based on configurable parameters.

Technical Specifications

| Manufacturer | Woodward |

|---|---|

| Model Number | 8237-1369 |

| Product Type | Electronic Governor / Control Module |

| Input Signal | Speed Sensor Inputs (Magnetic Pickups), Analog Setpoints |

| Output Signal | Current Output (4-20 mA or 20-160 mA) to Actuators |

| Supply Voltage | 24 V DC / 125 V DC (Depends on system configuration) |

| Operating Temperature | -40°C to +70°C |

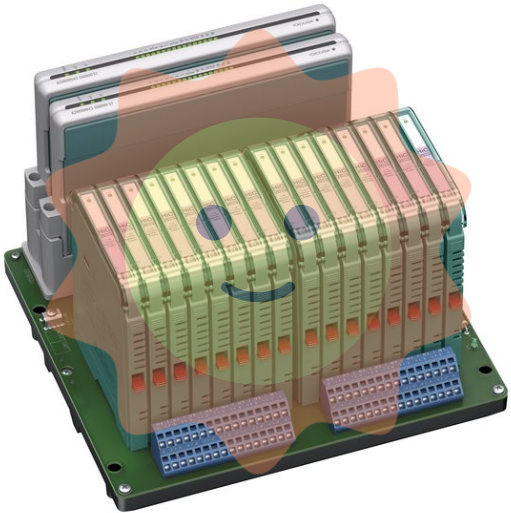

| Mounting | Panel Mount / Chassis Mount |

| Compliance | CE, UL, Industrial Standards for Control Devices |

Application in Power Generation & Industry

The primary application of the WOODWARD 8237-1369 lies within the power generation sector, where it acts as the primary governor for steam and gas turbine generator sets. In these applications, the controller is responsible for maintaining the grid frequency. It responds rapidly to grid disturbances, ramping power up or down to stabilize the network. Its ability to interface with automatic voltage regulators (AVRs) and plant DCS systems makes it a central element of the power island control strategy.

Beyond power generation, the 8237-1369 is extensively used in mechanical drive applications, such as compressors and pumps in the oil and gas industry. In these scenarios, precise speed control is vital for process optimization. For example, controlling the speed of a compressor to maintain pipeline pressure requires the governor to modulate the turbine power accurately. The 8237-1369’s reliability ensures continuous operation in remote locations, reducing the risk of costly unplanned shutdowns.

Integration and Reliability

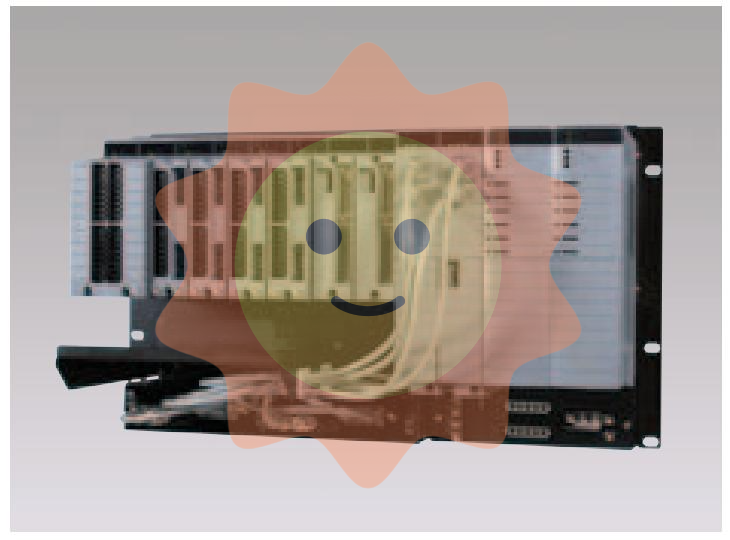

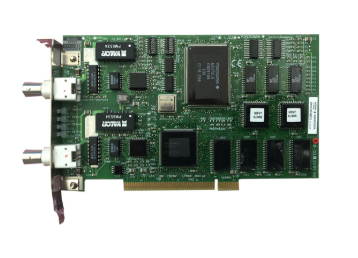

Woodward control systems are renowned for their durability, and the 8237-1369 continues this legacy. The module is designed with high-grade components capable of withstanding long-term exposure to industrial atmospheres. The circuitry includes protections against voltage transients and reverse polarity, preventing damage from common electrical faults.

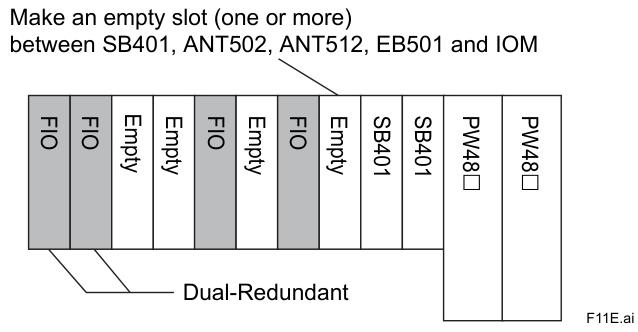

Integration is facilitated through a comprehensive array of terminal blocks for sensor inputs and actuator outputs. The module is typically configured via specific software tools, allowing engineers to tune PID parameters, define alarm setpoints, and customize the logic to match the specific thermodynamic characteristics of the prime mover. This flexibility ensures that the 8237-1369 can be optimized for unique application requirements, providing a tailored control solution rather than a "one-size-fits-all" approach.

Conclusion

The WOODWARD 8237-1369 Governor Control Module represents a critical investment in the operational reliability of industrial machinery. By offering precise speed control, robust load management, and flexible integration options, it ensures that turbines and engines operate at their peak performance. Whether used for maintaining grid stability or driving critical mechanical loads, this controller provides the precision and dependability that modern industrial operations demand.