SIEMENS SIMATIC Drive Controller System

SIEMENS SIMATIC Drive Controller System

Basic Framework and Security Standards

1. Positioning and safety warning

Scope: Covering the entire range of SIMATIC Drive Controllers, including CPU 1504D TF/1507D TF and SINAMICS Integrated, providing full process guidance from planning to maintenance, suitable for Motion Control scenarios such as multi axis machine tools, packaging machinery, printing equipment, etc.

Security level classification:

Warning type risk description example scenario

DANGER Fatal/Serious Personal Injury Contact with Live Parts, Undischarged Capacitors

Warning: May cause fatal/serious injury. Equipment damage may lead to electrical leakage, and wireless devices may interfere with safety functions

CAUTION Minor personal injury, electrostatic discharge damage to components

NOTICE property loss, wiring error leading to module failure

Qualification requirements: Only personnel with "industrial automation qualification" are allowed to operate, and they must be familiar with standards such as IEC 61131-2 and EN 60204.

2. Industrial network security (new core chapter added)

Protection strategy: Adopting the "Defense in Depth" framework, divided into 3 layers of protection:

Physical security: Lock the control cabinet door and manage access permissions (password/fingerprint)

Network security: network segmentation, firewall VPN、 Disable unused ports (such as NTP/PUT/GET)

System integrity: firmware updates, configuration verification, data backup

Key measures:

Regular firmware updates (via TIA Portal/memory card/web server)

Syslog log: CPU local cache security events (such as password errors, configuration tampering) can be forwarded to the server (UDP port 514/TLS port 6514)

Data destruction: Before retiring the device, a "factory reset" (SINAMICS first, CPU later) must be performed to format the storage card or physically destroy it

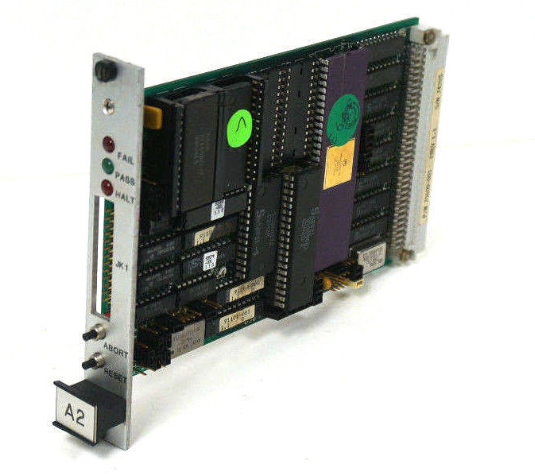

System Overview and Core Components

1. Comparison of Core Parameters of Controllers

Component model: CPU 1504D TF (for small and medium-sized applications) CPU 1507D TF (for high-end applications) Key differences

Code working memory 4 MB 15 MB 1507D supports more complex programs

Data working memory 6 MB 40 MB 1507D can store more real-time data

Number of positioning axes (maximum) 40 160 1507D Supports multi axis synchronization

Motion Control resources 3200 12800 1507D handle higher loads

Minimum cycle 500 μ s 250 μ s 1507D supports higher real-time performance

Integrated I/O 8 DI/DQ (X142) 8 DI/DQ (X142) Consistent

2. SINAMICS Integrated Function

Control mode:

Servo control: Maximum dynamic response, supports Dynamic Servo Control (DSC, 125 μ s cycle)

Vector control: maximum torque accuracy, 250 μ s current controller cycle

U/f control: suitable for fan/pump loads, 500 μ s cycle

Security function:

Basic functions: STO (Safe Torque Shutdown), SS1 (Safe Stop 1)

Extended functions: SS2 (Safety Stop 2), SBC (Safety Braking Control)

Advanced features: SLS (Safety Speed Limit), SLA (Safety Distance Limit), requiring 1 license per axis

Restrictions: Free Function Blocks (FBLOCKS) and SIMOTION CX32-2 extensions are not supported, only partial technical extensions (such as POLYGON/SETPGEN) are supported

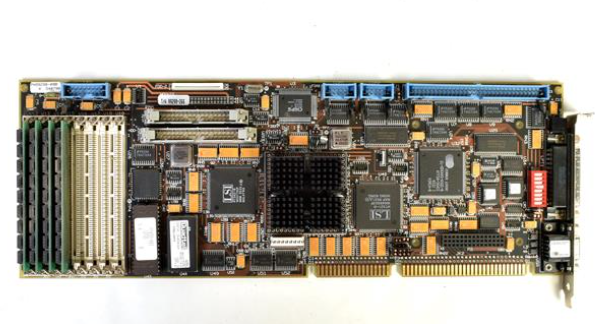

Application planning and installation wiring

1. Hardware configuration rules

Power configuration:

System power supply: 24V DC PELV (such as SITOP smart), no-load current 1.7A, maximum load 13.1A

Drive power supply: SINAMICS Line Module (generates DC link voltage), Motor Module takes power from the DC link

Communication configuration:

PROFINET IO IRT (X150): Supports isochronous mode, IRT level, synchronous multi drive

PROFIBUS DP (X126): Maximum of 12 I/O modules, does not support isochronous coupling

DRIVE CLiQ: 4 interfaces, each with 450mA power supply, connected to Motor Module/Encoder/Sensor Module (SMC)

2. Installation and wiring specifications

Installation requirements:

Guide rail: TH 35 standard guide rail (length 160-2000mm), fixed with M6 screws (torque 6Nm)

Gap: Top/bottom ≥ 80mm (heat dissipation), vertical installation (only allowed in the vertical direction)

Wiring rules:

Interface type wiring requirements, wire specifications

24V DC power supply 4-pin connector, distinguishing L+/M, stripping length 7-8mm 0.25-2.5mm ² (multi strand without sleeve)

PROFINET uses FastConnect cable, requires 8-core wire for 1000Mbps, and the 145 ° connector only supports 100Mbps CAT5e and above

DRIVE CLiQ shielded cable, the shielding layer is grounded through a metal bracket, with a maximum length of 100m Siemens specific DRIVE CLiQ cable

Digital I/O (X142) 24V DC, DI input delay 1 μ s/125 μ s, DQ high speed output (0.4A) Stripping length 10-11mm 0.25-1.5mm ²

Configuration and Debugging Process

1. Software configuration (TIA Portal+Startdrive)

Basic steps:

Create a project and add a Drive Controller (automatically generating CPU and SINAMICS Integrated devices)

Hardware configuration: Assign PROFINET device name/IP, configure SINAMICS driver object (Line Module/Motor Module)

Message configuration: default PROFIdrive message 393 (X122/X132 I/O), 105 (drive shaft)

Technical object configuration: Create positioning axis/synchronization axis/output cam, bind Drive Controller I/O (such as X142 Timer DI/DQ)

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- XYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Industry News

- XP POWER

Email:wang@kongjiangauto.com