WOODWARD 2301A Speed Control Controller: A Classic and Reliable Engine and Turbine Speed Control Solution

4. Key function adjustment

Low idle: At rated speed, open the "rated closed" contact and adjust the low idle potentiometer to the target idle speed.

Slope time: Adjust acceleration smoothness to avoid starting overspeed.

Starting fuel limit: Optimize the starting characteristics to ensure smooth starting and normal smoke exhaust.

Sag setting: Based on the requirements of parallel operation or isolated network operation, use a formula to accurately set the sag percentage.

Fault Diagnosis Guide (Abstract)

Possible causes of symptoms and solutions

The prime mover cannot start, the actuator does not operate, the polarity of the power supply is reversed, the voltage is low, or there is no power; Actuator malfunction; The fuel limit for starting is too low; No MPU signal; The lowest fuel contact is open circuit. Check the polarity voltage of the power supply; Check the actuator circuit and resistance; Adjust the starting fuel limit clockwise; Check the MPU signal voltage (≥ 1Vrms) and wiring; Check and close the lowest fuel contact.

The overspeed ramp time during startup is too short; The rated speed is set too high; Improper gain/reset adjustment; Engine malfunction. Increase slope time; Reset the rated speed; Optimize gain/reset dynamic adjustment; Check if the fuel rack is stuck.

Unstable operation (traveling block), improper adjustment of gain, reset, and actuator compensation; Speed setting potentiometer malfunction; Poor wiring shielding; The linkage mechanism is loose or stuck. Perform dynamic adjustments again; Check if the resistance of the potentiometer is stable; Ensure that all signal lines are properly shielded and grounded at a single point; Check the connection between the actuator and the fuel mechanism.

Unable to adjust the low idle setting below the mechanical minimum fuel position of the actuator at idle speed; Potentiometer malfunction. Increase the low idle setting or adjust the mechanical limit of the linkage mechanism; Replace the controller.

Product Support and Services

Woodward provides a multi-level technical support network:

OEM/Package Manufacturer Support: The best contact person for first-time programming and system integration issues.

Woodward Business Partners: including full-service distributors, authorized independent service facilities, and recognized engine modification providers, providing localized sales, service, and technical support.

Woodward direct support: available via email EngineHelpDesk@Woodward.com Or contact the Global Technical Support Center through the website.

The service options include: replacement/exchange (24-hour service), fixed rate repair, and fixed rate refurbishment.

When repairing equipment, it is necessary to obtain the repair authorization number in advance and provide a detailed description of the fault phenomenon and the type of repair required.

Summary of Safety Warning (must be followed)

Overspeed protection: The prime mover must be equipped with an overspeed shutdown device that is completely independent of the control system.

Emergency stop preparation: Emergency stop preparation must be made during startup to prevent runaway.

Personal protective equipment: Proper PPE (goggles, gloves, safety shoes, etc.) must be worn during operation.

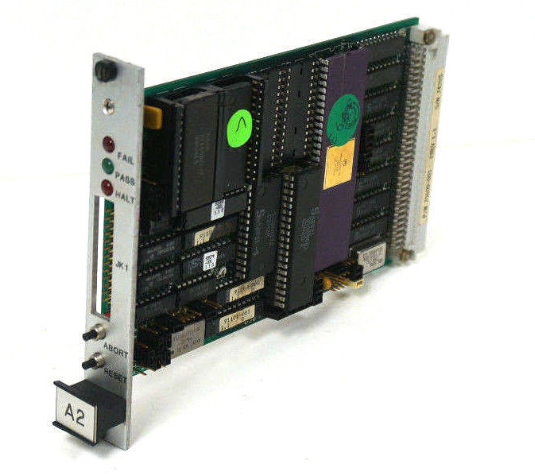

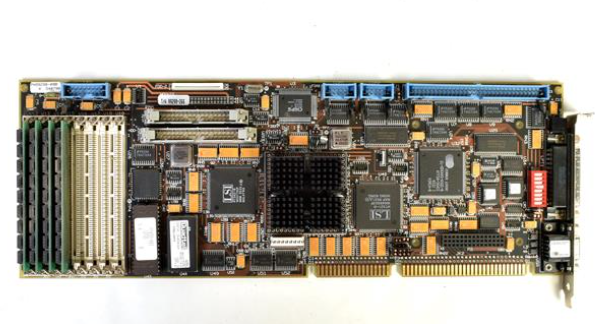

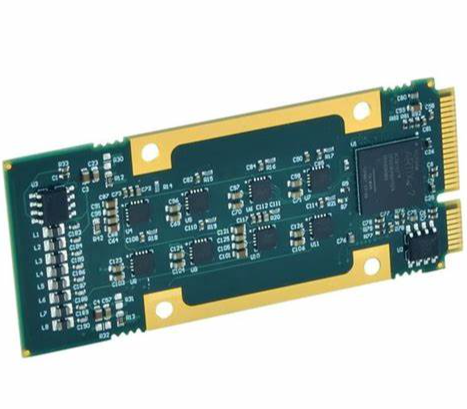

Electrostatic protection: When handling circuit boards, it is necessary to follow electrostatic discharge prevention measures and contact the grounding surface.

Minimum fuel contact: Never use as an emergency stop circuit.

Summary

The Woodward 2301A speed controller is an industrial grade speed control device with mature design, complete documentation, and network support. Its successful application relies on correct installation and wiring, meticulous shielding and grounding, adherence to standard debugging procedures, and strict compliance with safety warnings. For engineers and technicians engaged in power generation, shipbuilding, industrial drive and other fields, mastering the installation, commissioning and maintenance skills of 2301A is an important part of ensuring the stable, efficient and safe operation of key power systems.

Model Supplement

8402-319 8402-119

8237-1600

9907-147

5233-2089

9907-1106

5453-203

5453-277

5466-318

5466-425

8440-1706 A SPM-D11

8440-1666 B

5437-1067A

5448-890 SPM-D10

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- XYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Industry News

- XP POWER

Email:wang@kongjiangauto.com