HIMA HIQuad X System Manual: Comprehensive and in-depth analysis of HIMA SIL 3 safety automation system

4.1 Safety Integrity Level (SIL)

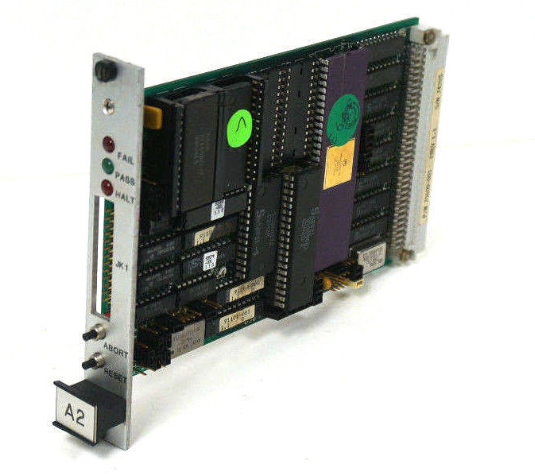

Processor: F-CPU 01 adopts a 1oo2 architecture (dual processor cross comparison) to ensure that processor failures do not result in the failure of safety functions.

Communication: Safety related communication is conducted through the SafeEthernet protocol.

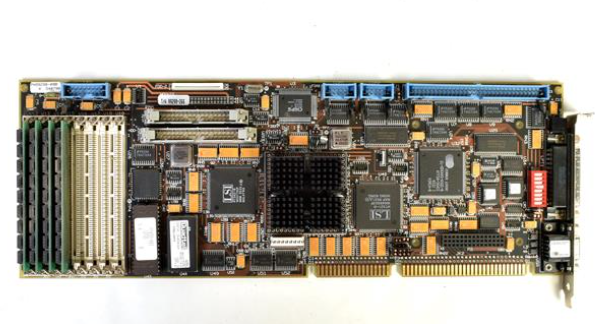

I/O module: The I/O module integrates the 1oo2 processor system through F-IOP 01 to ensure the safety related accuracy of signal acquisition and output.

4.2 Redundant Configuration

HIQuad X supports all-round redundancy:

Processor redundancy: Supports up to 2 processor modules (F-CPU 01) to run synchronously, achieving seamless hot standby.

I/O module redundancy: Supports module redundancy and channel redundancy. When a fault occurs, redundant modules take over and the system continues to operate.

System bus redundancy: Dual system buses (A/B) ensure high availability of communication links.

Power redundancy: Dual 24V power supply (L1+, L2+) combined with decoupling diodes to ensure that a single power supply failure does not affect system operation.

4.3 Noise Suppression

The system has built-in noise suppression function to cope with transient interference (such as voltage fluctuations).

Principle: Within the configured fault tolerance time (FTT) and safety time, the system automatically shields brief fault signals, maintains the last valid value, and avoids unnecessary system shutdown.

Configuration: Calculate the maximum and minimum noise suppression time using the "Safety Time" and "Watchdog Time" parameters in SILworX.

5. Power management and specifications

5.1 Power Requirements

Input voltage: 24V DC (standard 24V, allowable deviation -15% to+20%).

Power standard: Must comply with SELV or PELV standards.

Buffer capability: The power unit must be able to withstand a voltage drop of up to 20ms (if not met, F-PWR 02 buffer module must be used).

5.2 5V power supply distribution

The HIQuad X system provides independent 5V power supply for the I/O module and F-IOP module.

The 5V power supply is generated in the base rack through the F-PWR 01 unit and allocated to the I/O expansion rack.

Cable requirements: The resistance of the 5V power supply line must meet specific voltage drop requirements (H51X system resistance ≤ 40 m Ω per 12m length), and it is recommended to use shielded cables (LIY-CY).

5.3 Heat consumption calculation

When designing the heat dissipation of the control cabinet, it is necessary to consider the power consumption of all modules. HIQuad X provides a natural convection heat consumption calculation formula based on ambient temperature and installation method:

ΔTmax = Pv / (k * A)

Among them, Pv is the total power consumption of electronic components, k is the heat transfer coefficient (about 5.5 W/m ² K for steel cabinets), and A is the effective heat dissipation area.

6. Installation and mechanical specifications

6.1 Environmental conditions

Parameter specifications

Working temperature 0...+60 ° C

Transportation/storage temperature -40...+70 ° C

Pollution level 2

Altitude<2000 meters

Protection level IP20 (standard), if it needs to be installed in an IP54 cabinet according to EN 60204.

6.2 Mechanical Installation

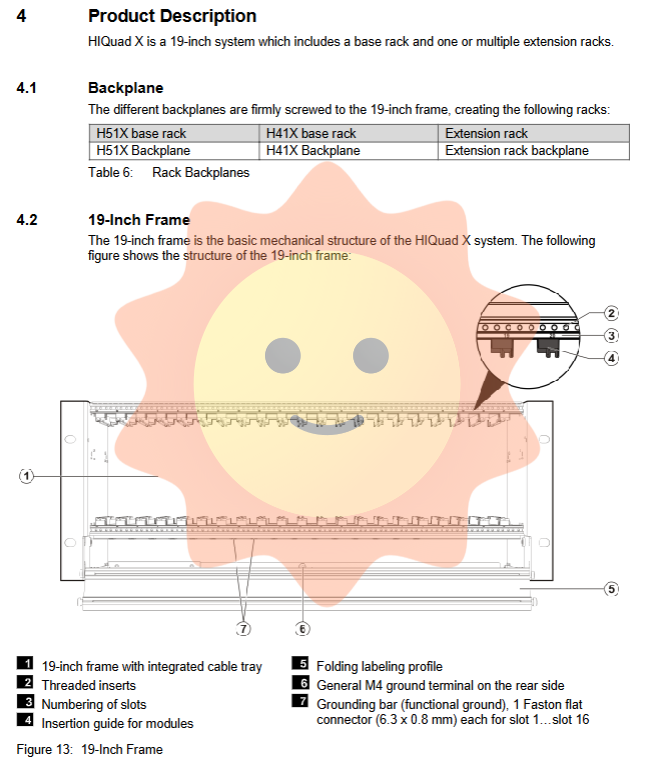

Size: Complies with the 19 inch standard.

Installation direction: I/O modules must be installed vertically.

Grounding and shielding: The surface of the system components has been treated with conductive chrome plating to achieve ESD protection. The rack and cabinet frame must be effectively connected through the equipotential grounding bar (25 mm ² grounding wire) provided by HIMA.

6.3 Ventilation Strategy

It is recommended to use HIMA K 9202B cabinet fan (top mounted) for forced ventilation.

The K 9203A rack fan is required for forced cooling below the expansion rack block.

The average heat consumption of the system through natural convection is about 300W (multiple cabinets arranged side by side), and adding fans can significantly improve the heat dissipation capacity (supporting a maximum total power consumption of 1000W).

7. Programming and Configuration (SILworX)

Tools: Use SILworX for project configuration, variable management, logic programming, and fault diagnosis.

Variable management: Supports global and local variables, and supports initial value setting (safety related variables must have safety initial values set).

Force: Used for testing and debugging, supports global and local force, and can set time limits and timeout actions (stop force or stop program).

User management: Supports multi-level user permission management (security administrator, read-write, read-only), and PES (controller) user account management (up to 10 user groups).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc