In depth analysis of HIMA Planar4 system: SIL 4 level hard wired safety logic solution

In depth analysis of HIMA Planar4 system: SIL 4 level hard wired safety logic solution

Introduction: Defining the highest standard of functional safety

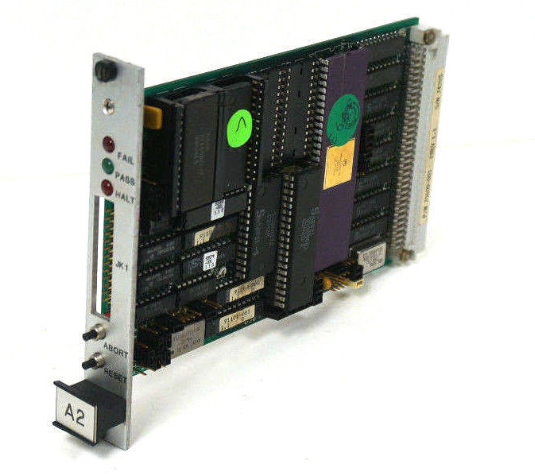

In the field of modern industrial automation, especially in processes with extremely high potential risks, functional safety is the core of system design. The HIMA Planar4 system was born for this purpose. As a security system based on hard wired logic, Planar4 abandons complex software programming and implements logical processing through physical wiring. This unique design not only eliminates the risk of software failures, but also ensures high availability and reliability of the system in extremely harsh environments.

This article will comprehensively analyze the technical characteristics, module configuration, and key role of Planar4 in industrial safety.

1. HIMA Planar4 System Core Architecture and Features

The HIMAX Planar4 system represents a "hard wired" safety concept, designed to provide absolute protection in places where ultimate safety is paramount.

1.1 Hardwired logic without software programming

Unlike traditional programmable logic controllers (PLCs), the application specific logic of the Planar4 system does not rely on software. On the contrary, it uses various wiring techniques - including soldering, Termipoint, or Wire Wrap - to directly implement logic functions on the backplane bus board. This approach fundamentally avoids software errors, virus attacks, or unauthorized logical modifications.

1.2 Highly integrated and scalable redundancy

Modular integration: Each Planar4 module integrates input, logic processing, and output functions.

Redundant architecture: All modules support redundant structure design, allowing users to expand the system according to their needs, thereby significantly improving system availability.

Safety level: The system complies with the IEC 61508 standard and can reach up to SIL 4 level, suitable for automation processes with extremely high potential risks.

1.3 Operating principles

The system follows the operating principle of "loss of excitation trip", which means that once a fault or loss of power is detected, the system will automatically enter a safe state to ensure safe shutdown of the process.

2. Global certification and compliance

The Planar4 system has been certified by multiple international authoritative standards, ensuring its applicability on a global scale

Functional safety standards: comply with IEC 61508 Part 1-7 (up to SIL 4) and ANSI/ISA-84.00.01-2004.

Industrial environment compatibility:

EN 50178:1997 (Electrical Installation Equipment)

IEC/EN 61000-6-2:2001 (Industrial Environment Immunity)

IEC/EN 61000-6-4:2001 (Emission Standard for Industrial Environments)

Explosion proof certification: Complies with EN 60079-15:2003 ATEX (Zone 2, T4) standard.

Applicability to harsh environments: Compliant with ANSI/ISA-S 71.04 Class G3 standard.

Compliance Directive: Complies with EMC Directive, Low Voltage Directive, and ATEX Directive.

3. Detailed module list and technical specifications

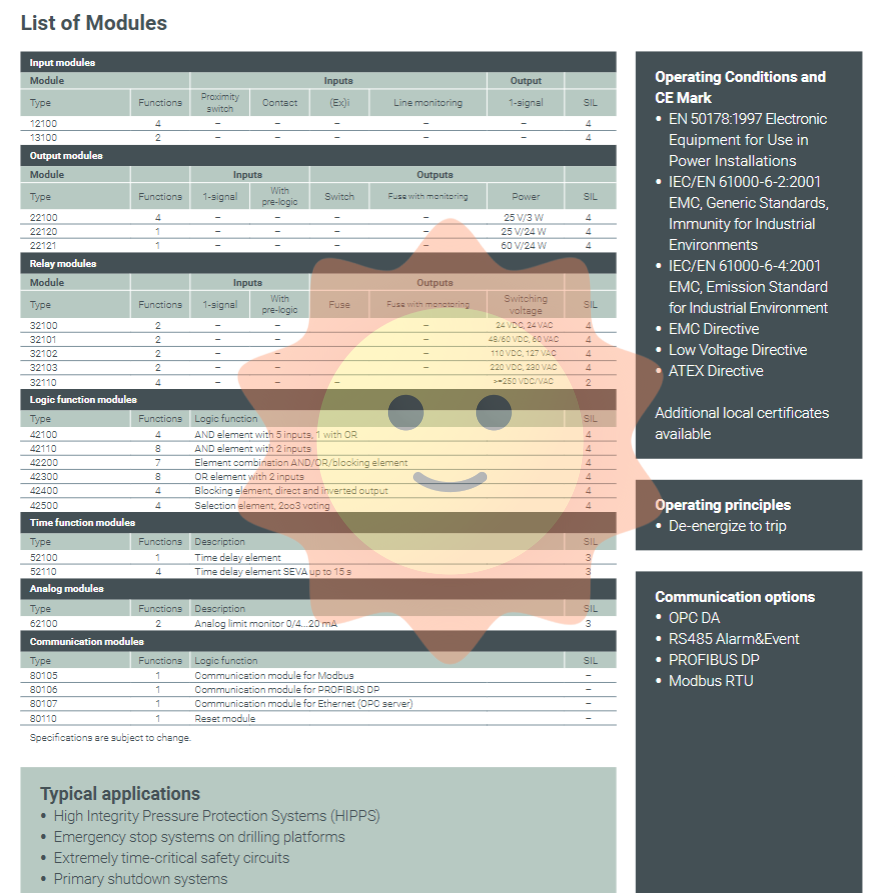

The Planar4 system has a rich series of modules, covering from simple input and output to complex logic processing and communication functions. The following is a detailed module classification and specification table.

3.1 Input module

The input module is responsible for receiving signals from on-site sensors, proximity switches, or contacts, and has line monitoring function.

Module model, number of functions, proximity to switch contacts (Ex), number of circuit monitoring signals, SIL level

12100 4 – – – – 4 4

13100 2 – – – – 4 4

3.2 Output module

The output module is used to execute control instructions, and some modules have pre logic functions and fuses with monitoring.

Module model, number of functions, number of signals, pre logic switch with monitoring, fuse power, SIL level

22100 4 – – – – 25 V / 3 W 4

22120 1 – – – – 25 V / 24 W 4

22121 1 – – – – 60 V / 24 W 4

3.3 Relay module

Provide isolated outputs of different voltage levels, suitable for field devices of various voltage specifications.

Module model, number of functions, number of signals, fuse with monitoring, fuse switch voltage, SIL level

32100 2 – – – 24 VDC, 24 VAC 4

32101 2 – – – 48/60 VDC, 60 VAC 4

32102 2 – – – 110 VDC, 127 VAC 4

32103 2 – – – 220 VDC, 230 VAC 4

32110 4 – – – >= 250 VDC/VAC 2

3.4 Logical Function Modules

This is the core of hard wired logic, which implements AND, OR, voting (2oo3) and other logic through physical wiring without programming.

Module model, function quantity, logic function description, SIL level

42100 4 has 5 input AND elements (including 1 with OR) 4

42110 8 has AND element 4 with 2 inputs

42200 7 element combination AND/OR/locking element 4

42300 8 OR element with 2 inputs 4

42400 4 locking element, direct and reverse output 4

42500 4 component selection, 2oo3 voting logic 4

3.5 Time Function Module

Used to implement security related delay functions.

Module Model Function Quantity Description SIL Level

52100 1 Delay Element 3

52110 4 Delay Element SEVA (up to 15 seconds) 3

3.6 Analog module

Used for processing continuous signals and conducting limit monitoring.

Module Model Function Quantity Description SIL Level

62100 2 Analog Limit Monitor 0/4... 20 mA 3

3.7 Communication module

Although the core logic of the system is hard wired, Planar4 still provides communication interfaces for alarms, events, and resets.

Module Model Quantity Function Description SIL Level

80105 1 Modbus Communication Module -

80106 1 PROFIBUS DP Communication Module -

80107 1 Ethernet Communication Module (OPC Server) -

80110 1 Reset Module -

The supported communication options include:

OPC DA

RS485 Alarm & Event

PROFIBUS DP

Modbus RTU

4. Typical application scenarios

With the highest safety level of SIL 4 and highly deterministic hard wired characteristics, the HIMA Planar4 system is mainly applied in the following key areas:

High Integrity Pressure Protection System (HIPPS): prevents catastrophic accidents caused by overpressure in pipelines and high-pressure processes.

Emergency Shutdown System (ESD) for Drilling Platforms: Ensure the safe shutdown of personnel and the platform in extreme environments.

Extremely time critical safety circuits: scenarios that require extremely high response speed and cannot tolerate system delays or software scanning cycles.

Main shutdown system: serves as the last line of defense for the factory or the entire production line.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc