What are the core protection mechanisms of WOODWARD Vertex's anti surge control?

What are the core protection mechanisms of WOODWARD Vertex's anti surge control?

Applications

The Vertex control is designed to control and protect industrial sized axial or centrifugal compressors. This controller includes specifically designed algorithms and logic to start, stop, control, and protect industrial compressors driven by a stationary speed motors, variable frequency drive motors, or turbines. OEM qualified algorithms are used within the Vertex control for straight-through, isocooled, double flow, stand alone, and back-to-back compressor applications.

The Vertex controller is field configurable allowing users to configure/select the specific control algorithm required for the specific compressor loop and application. The control’s special stage-to-stage and performance controller decoupling logic allows stable control during normal compressor operation as well as during plant upsets, minimizing process over or undershoot conditions.

This purpose-built controller has the control, protection, and decoupling logic required for one or two recycle loop compressor applications. OEM qualified algorithms are used to ensure that proper start sequences are followed, proper and accurate compressor load calculations are used, and proper protection and recovery actions are performed.

Basic functionality includes:

Motor or Turbine Drive Interface Logic

Inlet Throttle Valve Control

Inlet Guide Vane Control

Recycle Valve(s) Control

Anti-Surge Control (1 or 2 Recycle Loops)

Performance Control (suction or discharge pressure or process flow)

Surge Anticipation Logic

Surge Protection Logic

Surge Recovery Logic

Load Sharing (Parallel compressors, up to five Trains)

Optionally users can apply Vertex controllers in simplex or dual-redundant controller configurations. When applied in simplex configurations, a single Vertex controller is used to control and protect the compressor. When applied in dual-redundant controller configurations, two Vertex controllers are connected together in a parallel fashion with one unit functioning as the system controller (SYSCON), and one unit functioning as the backup controller (BACKUP). With dual-redundant configurations, transfer from the SYSCON to BACKUP controller is performed automatically upon a SYSCON failure, or manually by an operator for system and transfer verification purposes.

In dual-redundant applications, depending on system design, anti-surge valve movement during SYSCON and BACKUP controller transfer can either be bumpless (no-movement) or up to ~80 milliseconds in the open direction. To ensure system up-time with dual-redundant applications either Vertex controller (SYSCON of BACKUP) can be repaired and or replaced with the compressor operating on-line normally.

For applications where the compressor’s anti-surge valve (ASV) stays closed for long periods of time, the Vertex includes a special on-line ASV test routine to test and verify valve movement with little or no effect on compressor or process operation. With this special ASV test routine plant operators can now verify ASV health and performance without reducing production levels or effecting system availability.

Designed to function as a plant DCS node the Vertex controller can be configured to interface with the plant DCS via hardwired inputs/output signals or serial or Ethernet communications. With the capability to monitor and control all compressor based functions (i.e. bearing temperatures, vibration levels, control oil levels, etc.) the Vertex controller is ideal for use as a cost-effective compressor control/protection as well as a plant DCS monitoring node.

Designed to replace old obsolete anti-surge controllers, the Vertex can be configured to function like these controllers but uses faster scan rates, improved surge anticipation logic, and one integrated package for all control functions (anti-surge control loop 1, anti-surge control loop 2, and performance control). Also, for load sharing function, no need for additional Master controller hardware.

Description

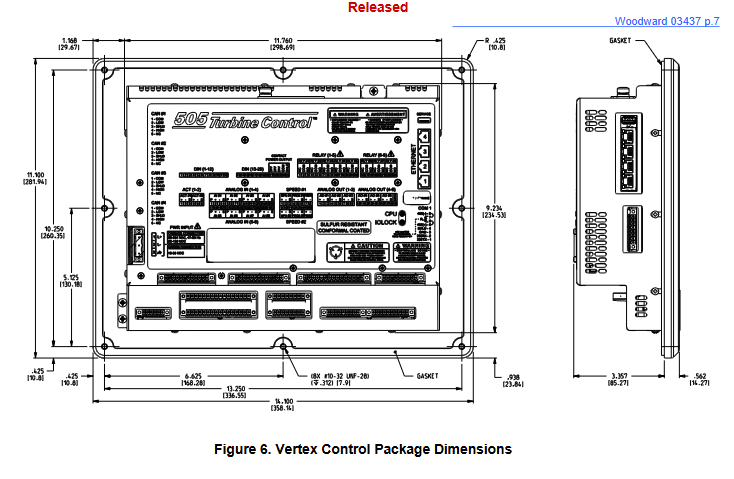

The Vertex control is packaged in an industrial hardened enclosure designed to be mounted within a system control panel located in a plant control room or next to the compressor. The control’s user-friendly front panel serves as both a programming station and operator control panel (OCP). This user-friendly front panel allows engineers to access and program the unit to the specific plant’s requirements, and plant operators to easily start/stop the compressor and enable/disable any control mode. The controller’s 8” graphical display allows operators to view actual and setpoint values from the same screen, simplifying compressor operation.

The control’s front panel serves as both a programming station and OCP. Password security is used to protect all unit program mode settings. The controller’s 8” graphical display allows operators to view actual and setpoint values from the same screen, simplifying turbine operation.

With dual-redundant Vertex controller applications, the front panels of both units function as redundant operator control panels and can be utilized to manage and monitor compressor operation.

Ethernet and serial communications allow users to easily connect the Vertex in to plant or process control system. All controller inputs, outputs, and statuses can be monitored and all start/stop or enable/disable commands can be given through industry standard Modbus TCP or OPC protocols. The Vertex control uses SNTP (synchronized network time protocol) over Ethernet to allow users to synchronize the control’s real-time clock to the plant distributed control system.

Compressor and motor interface input and output-wiring access is located on the controller’s lower back panel. Unpluggable terminal blocks allow for easy system installation, troubleshooting, and replacement. Optionally users can increase the number of inputs and outputs signals to/from the Vertex control by connecting RTCNet distributed I/O nodes to the controller’s CAN communication ports and configuring the control to use the connected distribute inputs and outputs. The following additional I/O signals can be connected to the Vertex control via CAN communications:

(16) 4-20mA input channels and (4) 4-20mA output channels (via 2 RTCNet AIO module)

(8) RTD signals (via 1 RTCNet RTD module)

(16) Discrete Inputs (via 1 RTCNet DI module)

(16) Relay output drivers (via 1 RTCNet DO module)

The Vertex controller includes the following PID control & protection functions:

Performance Control PID,Rate PID Control

Performance Limiter PID,Boost (open-loop backup line response)

Anti-Surge PID Control,Surge Recovery

Surge Minimum Position,Start, Purge, Stop, Shutdown, & Zero Speed Sequencing Positions

Alarm & Shutdown Logic,Load sharing among 5 trains with no additional hardware for Master Controller.

Easy Load sharing setup. (Plug and Play configuration).

Independent PID (gland seal steam, other)

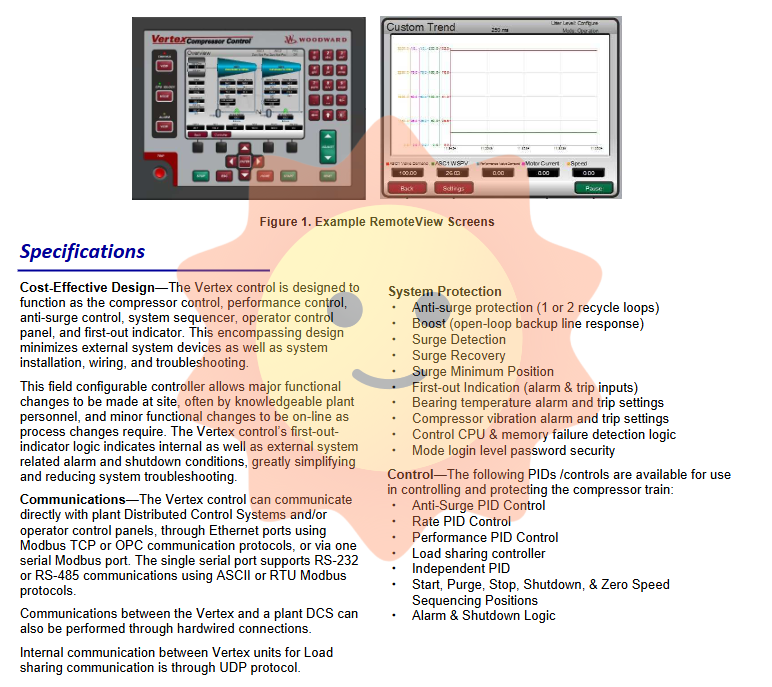

Optionally users can utilize Woodward’s RemoteView software program with the Vertex control to function as a remote operator control panel and or engineering station. This software program once loaded onto a remote computer or touch panel, allows the user to perform all of the Vertex control’s front panel display functions (monitor, operate, tune, and configure) on the respective computer or touch panel. Password based login level security is utilized with this software program to allow users to manage what functions they want the remote panel user to have.

The Vertex controller includes a suite of service tools to allow users to perform the following functions:

Upload configuration settings files from the Vertex to save on another device

Download configuration settings files to the Vertex

Download and view DataLog files

View real-time or saved trend files

Specifications

Cost-Effective Design—The Vertex control is designed to function as the compressor control, performance control, anti-surge control, system sequencer, operator control panel, and first-out indicator. This encompassing design minimizes external system devices as well as system installation, wiring, and troubleshooting.

This field configurable controller allows major functional changes to be made at site, often by knowledgeable plant personnel, and minor functional changes to be on-line as process changes require. The Vertex control’s first-outindicator logic indicates internal as well as external system related alarm and shutdown conditions, greatly simplifying and reducing system troubleshooting.

Communications—The Vertex control can communicate directly with plant Distributed Control Systems and/or operator control panels, through Ethernet ports using Modbus TCP or OPC communication protocols, or via one serial Modbus port. The single serial port supports RS-232 or RS-485 communications using ASCII or RTU Modbus protocols.

Communications between the Vertex and a plant DCS can also be performed through hardwired connections.

Internal communication between Vertex units for Load sharing communication is through UDP protocol.

System Protection

Anti-surge protection (1 or 2 recycle loops)

Boost (open-loop backup line response)

Surge Detection

Surge Recovery

Surge Minimum Position

First-out Indication (alarm & trip inputs)

Bearing temperature alarm and trip settings

Compressor vibration alarm and trip settings

Control CPU & memory failure detection logic

Mode login level password security

Control—The following PIDs /controls are available for use in controlling and protecting the compressor train:

Anti-Surge PID Control

Rate PID Control

Performance PID Control

Load sharing controller

Independent PID

Start, Purge, Stop, Shutdown, & Zero Speed

Alarm & Shutdown Logic

Control Specifications

INPUTS

Power:LV models = 18 - 36Vdc

HV models = 88 - 264Vac & 90-150Vdc (50 watts max)

Speed:(2) Passive MPUs or 2 Active Proximity probes (0.5 – 32,000 Hz)

Discrete Inputs:(19) Configurable Contact Inputs (optionally (16) additional inputs via RTCNet module)

Analog Inputs:(8) Configurable 4-20mA Inputs

(optionally (16) additional inputs via RTCNet module)

OUTPUTS

Valve/Actuator Drivers:(2) Actuator Output, 4-20mA or 20 200mA

Discrete Outputs:(7) Relay Outputs (24Vdc @ 2 amps,

Form-C contacts) (optionally 16 additional outputs via RTCNet module)

Analog Outputs:(6) 4-20 mA Outputs (optionally 4

additional outputs via RTCNet modules)

COMMUNICATIONS

Ethernet:(3) customer ports (Modbus TCP or OPC) Simplex versions,

(2) customer ports (Modbus TCP or OPC) Redundant versions,

(1) Port Service Tool use

Serial:1 Modbus port (ASCII or RTU) Comm Ports (RS-232 or RS-485 compatible)

CAN: (4) ports (RTCNet comm. protocol)

Features

Configurable for dual-redundant applications

Integrated operator control panel

Surge prevention, detection & recovery logic

Security (program is password protected)

First-Out indication (alarms & shutdowns)

On-line Anti-Surge Valve Health Test

Remote analog setpoints for Performance control

Bearing temperature monitoring/alarms/trips

Vibration monitoring/alarms/trips

Control Accessories

RTCNet Modules—Optionally users can apply Woodward distributed I/O modules to extend the Vertex controller’s input and output channels

Vibration Sensor Kit—Optionally users can apply 4-20mA accelerometer sensors with the Vertex to monitor unit vibration levels and alarm & trip on high vibration events. Refer to product manual for related kit part numbers

RemoteView—Woodward’s RemoteView software program once installed on a computer or touch panel can be used as an engineering workstation and or remote operator control panel.

Stored Trend/Log File Service Tool – Woodward’s Control Assistant software service tool can be used to view real-time trends, saved trend files, upload and download Vertex control’s configuration files and alarm/trip logs

Operating Conditions

–30 to +70 °C ambient air temperature range

Humidity: Lloyd’s ENV2 test #1

Dry Heat: Lloyd’s ENV3

Salt Fog: US MIL-STD-810 method 509.2 procedure 1

Shock: meets US MIL-STD-810C, method 516.2-1, procedure 1B

Vibration: Lloyd’s ENV2 test #1

Pollution Resistance

Particulate Pollution Resistance: IEC 60664-1 Pollution Degree 2 (normally only non-conductive pollution occurs)

IEC 60068-2-60:1995 Part 2.60 Methods 1 and 4 (Flowing Mixed Gas Corrosion Test)

Gaseous Pollution Resistance: Module conformal coating withstands NO2, CO2, SO2, and H2S gases

Will withstand levels typical of telecommunications and computer installations as defined by Battelle Labs Class III (between

IEC60721-3-3 classification 3C1 and 3C2, light industrial to urban industrial, heavy traffic)

Regulatory Compliance

European Compliance for CE Marking

These listings are limited to only those units bearing the CE Marking.

EMC Directive: 2014/30/EU COUNCIL DIRECTIVE

LVD Directive: 2014/35/EU COUNCIL DIRECTIVE

ATEX Directive: 2014/34/EU COUNCIL DIRECTIVE 2, Category 3, Group IIG Ex ic nA IIC T4 X Gc IP20

Other International Compliance

IECEx Ex ic nA IIC T4 Gc: Certificate No. IECEx CSA 15.0020X

North American Compliance

CSA Listed for Ordinary Locations Certificate 70006135 (LR 79726)

CSA Listed for Class I, Division 2, Groups A, B, C, and D, T4 at +70 °C: Certificate 70006135 (LR 79726)

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc