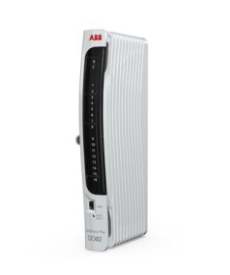

ABB SPHSS03 Hydraulic Servo Module

Overview

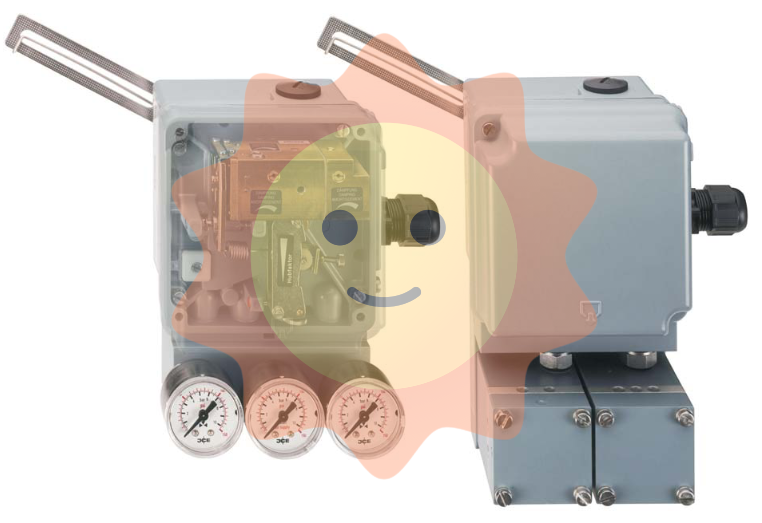

Product Definition and Function: The ABB SPHSS03 Hydraulic Servo Module is a module specifically designed for the control of hydraulic systems. Its main function is to convert electrical signals into hydraulic signals to accurately control the movements of hydraulic actuators (such as hydraulic cylinders and hydraulic motors), including position, speed and force control. In the field of industrial automation, this module is essential for achieving high-precision mechanical movements, for example, it plays a key role in machine tool processing, injection moulding and engineering machinery.

Principle of operation

Signal conversion process

Input Signal Processing: The module receives electrical signals from the control system (e.g. PLC or industrial computer), which can be analogue signals (e.g. - 10V - + 10V voltage signals or 4 - 20mA current signals). The modules first condition these input signals, including filtering, amplification and linearisation. For example, high-frequency interference components are removed from the signal by filtering circuits to make the signal smoother, and amplification circuits are used to amplify weak signals to a suitable amplitude to meet the requirements of subsequent processing. Linearisation is to ensure a good linear relationship between the input signal and the desired hydraulic output parameters (e.g. flow, pressure).

Electro-hydraulic converter: The processed electrical signal is used to drive an internal electro-hydraulic converter, usually a proportional solenoid valve or servo valve. In the case of proportional solenoid valves, for example, the spool of the solenoid valve is displaced when the input electrical signal changes. The magnitude of the electrical signal determines the amount of spool displacement, which in turn controls the flow and pressure of hydraulic fluid through the solenoid valve. This precise control relationship allows the module to achieve fine regulation of the hydraulic actuator based on the input electrical signal.

Hydraulic Control and Feedback Regulation

Hydraulic Actuator Control: Hydraulic fluid from the electro-hydraulic converter is directed to the hydraulic actuator. For position control applications, precise displacement of the hydraulic cylinder piston can be achieved by precisely controlling the flow and direction of the hydraulic fluid. For example, in a tool feed system for an automated machine tool, based on position commands from the CNC, the SPHSS03 module precisely controls the flow and direction of the hydraulic fluid into the hydraulic cylinder, allowing the tool to cut with a predetermined trajectory and precision. For speed control, the movement speed of the hydraulic actuator is controlled by regulating the flow of hydraulic fluid. As for force control applications, the module is used to achieve the desired force output from the hydraulic actuator by adjusting the pressure of the hydraulic fluid, such as applying precise pressure to a specimen in a material testing machine.

Feedback Control Principle: In order to achieve highly accurate control, SPHSS03 modules are usually equipped with feedback sensors. These sensors can be linear displacement sensors for measuring the position of the hydraulic actuator, velocity sensors for speed measurement or pressure sensors for pressure measurement. The sensors feed the actual motion parameters of the hydraulic actuator (e.g. actual position, actual speed or actual pressure) back to the module. The control circuit inside the module compares the feedback signal with the input desired signal and calculates an error signal. Based on this error signal, the control circuit adjusts the electrical signal output to the electro-hydraulic converter, so that the actual motion of the hydraulic actuator continuously converges to the desired motion until the error is reduced to within the permissible range.

Performance characteristics

High-precision control performance: High-precision hydraulic control can be achieved, position control accuracy can reach the micron level, for example, in the application of precision machine tools, the position control accuracy of ±0.001mm - ±0.01mm can be achieved. Speed control accuracy is also very high, and can be accurate to about ±0.1% - ±1% of the set speed. Force control accuracy is also excellent, achieving ±0.5% - ±2% of rated force in some force control scenarios, making it an excellent performer in industrial applications where control accuracy is critical.

Fast Response: The module has a fast response capability with short response times to input signals. Generally speaking, for the step input signal, its response time can reach a few milliseconds (such as 1 - 10ms), this fast response characteristics make the hydraulic actuator can be quickly in accordance with the instruction action, in the high-speed automated production process is very important, such as in the high-speed injection moulding machine or rapid stamping equipment, can effectively improve production efficiency.

High reliability and stability: high quality electronic components and precision hydraulic components are used, and the harsh conditions of the industrial environment are fully considered in the design. Its housing usually has good protection level, such as IP54 or higher, can effectively prevent the intrusion of dust and liquid. In terms of temperature adaptability, it is able to work stably within a temperature range of - 10°C - + 50°C (may vary according to specific models). At the same time, the internal circuitry and hydraulic system of the module have been strictly designed for electromagnetic compatibility (EMC), which can resist the electromagnetic interference common in industrial sites and ensure the stable operation of the system.

Flexible Configuration and Adaptability: The SPHSS03 module is flexible and can be configured through software or hardware. For example, users can set the control parameters of the module through the software interface or hardware dip switches, such as control gain, integration time, differential time, etc., in order to adapt to different hydraulic system characteristics and control requirements. It can also support a variety of operating modes, such as position control mode, speed control mode and force control mode switching between different application scenarios to facilitate the use.

Technical Parameters

Input parameters

Signal type and range: Analogue voltage signals (typical range - 10V - + 10V) and analogue current signals (4 - 20mA) are supported as control inputs. These signals have a high resolution, e.g. voltage signals may have a resolution of up to 1mV and current signals may have a resolution of up to 0.1mA, to enable fine control command inputs.

Signal update frequency: The ability to receive higher frequency signal updates, up to several kilohertz (e.g. 1 - 5kHz), depending on the specific application requirements and module configuration, ensures that the module is able to respond to fast-changing control commands in a timely manner.

Output parameters

Hydraulic oil flow control range: Depending on the module design and application scenario, the hydraulic oil flow control range varies. Generally speaking, the minimum flow control can reach a few millilitres per minute (e.g. 0.1 - 10ml/min), and the maximum flow control can reach dozens of litres per minute (e.g. 1 - 50L/min) to meet the needs of hydraulic actuators of different sizes and powers.

Hydraulic oil pressure control range: the pressure control range is usually from 0MPa to about 30MPa, some special models may support higher pressure control range, which can provide precise control for different pressure levels of hydraulic system.

Performance Parameters

Position Control Accuracy: As mentioned above, the position control accuracy ranges from ±0.001mm - ±0.01mm, depending on a variety of factors such as the accuracy of the sensor, the stability of the hydraulic system and the control algorithm.

Speed control accuracy: the speed control accuracy can reach ±0.1% - ±1% of the set speed, through accurate flow control to achieve stable speed control of the hydraulic actuator.

Response time: Response time is between 1 - 10ms for step input signals, this fast response capability helps to improve the dynamic performance of the hydraulic system.

Physical Parameters

Dimensions: The external dimensions are usually designed for easy mounting in a control cabinet or specific location in the equipment. They may be between 8cm - 15cm in length, 4cm - 8cm in width, 2cm - 6cm in thickness and have standard mounting holes for easy fixing to equipment brackets or cabinets.

Weight: Relatively light weight, generally between 0.5kg - 2kg, will not cause excessive burden on the installation and structure of the equipment.

Environmental parameters

Operating Temperature Range: It can work stably in the temperature range of - 10℃ - + 50℃, adapting to the temperature conditions of most industrial sites. In some specially designed models, the working temperature range may be wider.

Humidity range: The relative humidity range is generally 10% - 90% (non-condensing), ensuring normal operation in different humidity environments.

Anti-electromagnetic interference capability: Complies with relevant industrial electromagnetic compatibility standards, such as EN 61000 - 6 - 2 (Industrial Environmental Immunity) and EN 61000 - 6 - 4 (Industrial Environmental Emission) standards, and is able to effectively resist electromagnetic interference and radio frequency interference in industrial sites.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com