HIMA HICore 1 In Depth Analysis: A Comprehensive Guide to Functional Safety SoCs, Evaluation Kits, and T Ü V Certification

HIMA HICore 1 In Depth Analysis: A Comprehensive Guide to Functional Safety SoCs, Evaluation Kits, and T Ü V Certification

In the field of industrial automation and functional safety, HIMA Paul Hildebrandt GmbH has always been at the forefront of the industry. The HICore 1 security chip launched not only represents highly integrated system on chip technology, but also a rigorously certified security related processor system. This article will deeply analyze the technical characteristics of HICore 1, T Ü V certification details, and application advantages of the evaluation kit based on the latest technical documents and certification information, providing comprehensive technical references for developers.

Overview of HICore 1 Security Chip: Excellent Design with On Chip Redundancy

HICore 1 is a safety related integrated circuit designed specifically for safety critical applications. It adopts advanced on-chip redundancy technology, integrates a secure processor system, communication controller, and rich I/O ports. Its physical packaging adopts BGA 256 form, which can provide high reliability safety control in harsh industrial environments.

Core Architecture and Performance

HICore 1 is based on the DP80390 (8-bit) processor core. Although its architecture is classic, it achieves a balance between energy efficiency and performance through modern design

High performance: The maximum clock frequency can reach 100 MHz.

Low power design: Supports APL (Advanced Physical Layer) power level, with a power consumption of only 540 mW in Class A mode and 1100 mW in Class C mode, making it very suitable for energy sensitive application scenarios.

Wide temperature operation: Industrial grade temperature range supports -40 ° C to+85 ° C, suitable for various extreme environments.

Safety Integrity Level (SIL/PL)

As a core product of the HIMA Smart Safety concept, the HICore 1 safety platform has passed multiple top-level international safety certifications:

IEC 61508: Compliant with SIL 3 (Safety Integrity Level 3) standard.

ISO 13849-1: Achieve PL e (performance level e)/Category 4.

EN 62061: Complies with corresponding safety requirements.

This makes HICore 1 not only suitable for process automation, but also fully meets the high standard safety requirements of factory automation.

T Ü V Rheinland Certification and Document Compliance

For safety critical equipment, certification from authoritative institutions is the cornerstone of product compliance. According to the latest revised list issued by T Ü V Rheinland Industrie Service GmbH, the certification status of HICore 1 remains valid.

Certification Details

Certificate Number: 968/EL 719.04/23

Testing agency: T Ü V Rheinland Industrie Service GmbH (Automation, Funktionale Sicherheit & Cyber Security)

Report Number: 968/EL 719.02/18 (Status: valid)

Document revision process

The technical documentation of HICore 1 is constantly updated with technological advancements to ensure continuous compliance with the latest safety standards. The current latest document status is as follows:

Safety Manual: HI_801_077_2H_HICore_1_SoC_Safety_Sanual.pdf (Rev. 2.00, Status: valid)

Revision history:

2013: Initial version based on report 968/EL 719.01-13.

2018: First update based on 968/EL 719.02/18.

2023: Based on the latest update of 968/EL 719.04/23, reflecting the latest certification status.

The manufacturer and certification body have reached an agreement on the content of the revision list, ensuring the authority and accuracy of the document.

HICore 1 Assessment Kit: Fast Track for Accelerating Safety Product Development

To assist engineers in quickly assessing the usability and flexibility of HICore 1, HIMA provides a complete evaluation kit. These kits are not only tools for verifying chip functionality, but also an ideal platform for developing application software during the target hardware design phase.

1. Development environment and delivery scope

The HIMA assessment kit provides a comprehensive development experience that is "out of the box", including hardware, software, and necessary debugging tools:

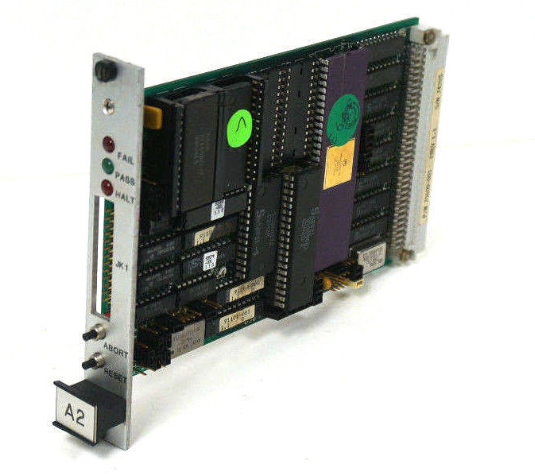

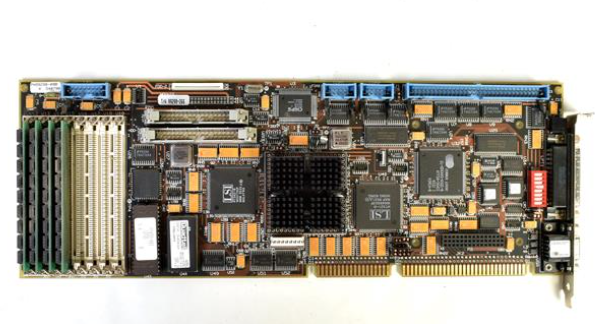

Core hardware: HICore 1 evaluation board or Ethernet APL security evaluation board.

Software package: Pre installed software that complies with IEC 61508 SIL 3, ISO 13849 PLe, and EN 62061 standards, including a secure operating system and secure middleware.

Development toolchain: IAR Embedded Workbench for 8051.

Debugging tool: DCD HAD2 JTAG Bugger.

Document support: Comprehensive digital documents, security manuals, and hardware design guidelines.

Accessories: 24V switch power supply, anti-static protection pad, RS232/422/485 USB adapter, etc.

2. HICore 1 communication capability

HICore 1 supports a wide range of industrial communication protocols, particularly with deep optimization for secure communication:

Non secure communication: CANopen Safety, PROFInet, Ethernet/IP, CANopen.

Safety communication: PROFIsafe, CIP Safety, Failed Safe over EtherCAT (FSoE), CANopen Safety.

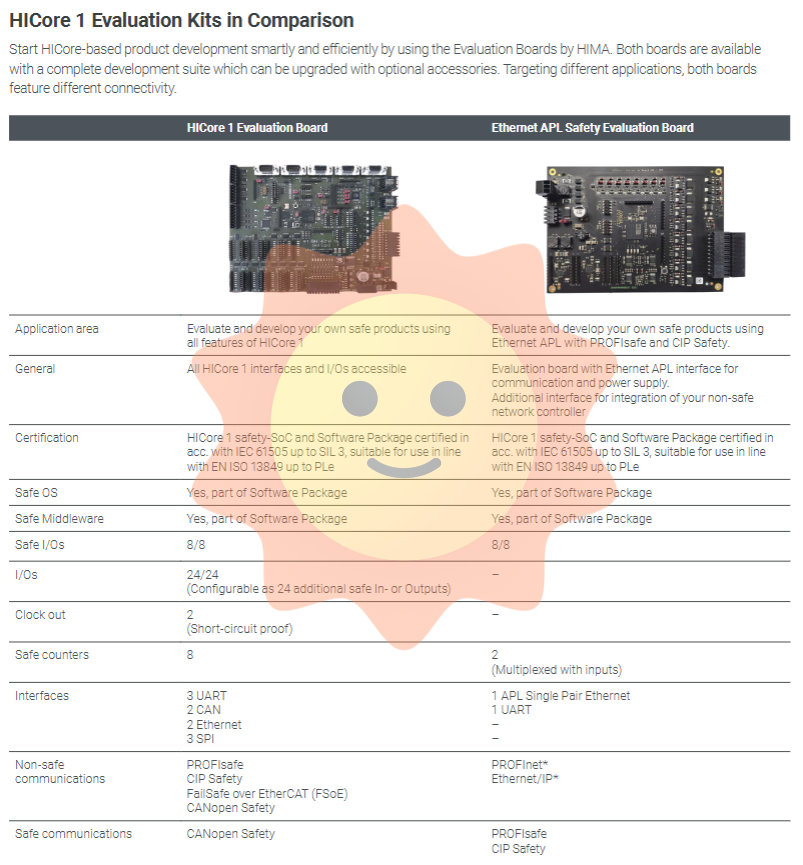

Deep comparison of evaluation kits: Standard version vs. Ethernet APL version

HIMA provides two evaluation boards with different functions for different application scenarios. Here is a detailed comparison between the two to help developers choose the most suitable tool.

Feature Comparison Table

Features HICore 1 Evaluation Board (Standard Edition) Ethernet APL Security Evaluation Board

The core application areas utilize all the features of HICore 1 to evaluate and develop independent safety products. Specially developed for applications that utilize Ethernet APL (Single Pair Ethernet) combined with PROFIsafe and CIP Safety.

The main interface is universal and can access all HICore 1 interfaces and I/O. Integrated Ethernet APL interface (for communication and power supply), with additional interfaces for integrating non secure network controllers.

Safety I/O 8/8 (8 inputs/8 outputs) 24/24 (24 configurable safety inputs or outputs)+2 clock outputs (short circuit protection)

8 safety counters and 2 (multiplexed with input)

Communication interface 3x UART, 2x CAN, 2x Ethernet, 3x SPI 1x APL Single Pair Ethernet, 1x UART

Supported protocols support all standard protocols emphasizing PROFIsafe, CIP Safety over Ethernet APL

Applicable scenario analysis

HICore 1 evaluation board: suitable for the development of general safety control systems, requiring scenarios with rich I/O and multiple bus interfaces.

Ethernet APL Safety Assessment Board: represents the cutting-edge trend of # safetygoesdigital, suitable for modern process industry applications that require long-distance transmission, high-speed communication, and power over Ethernet.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc