HIMA HIMatrix F35 Safety Controller: Specification Manual, SIL 3 Programming and Installation Guide

Counter module (HSC 2)

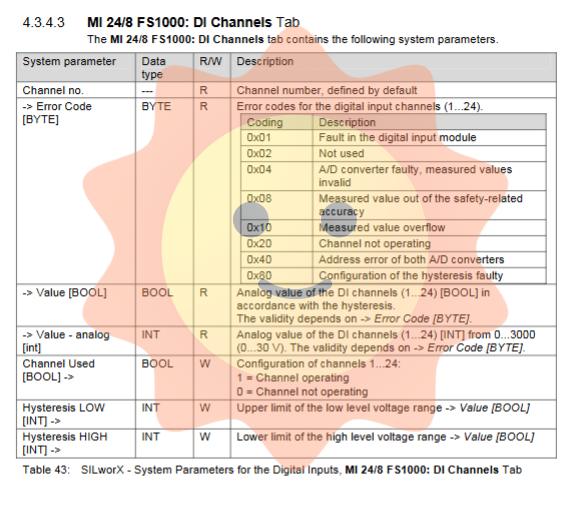

Input module (MI 24/8)

System parameters and error codes:

Users can read detailed error codes through system variables.

Example of digital output error code:

0x0001: Digital output internal fault.

0x0002: MOT test for safety switch 1 returned a fault.

0x0200: All outputs are turned off, total current exceeds limit.

Example of simulated input error code:

0x0004: MOT Test: Conversion Time Monitoring.

0x0008: FTT test: Data bus inspection fault.

4.2 Connection variants and configurations

F35 supports special connection variants to meet specific security application requirements:

4.2.1 Mechanical contact connections on analog inputs

Connect the mechanical contacts to the analog input through the Z 7308 shunt adapter. This connection method utilizes analog input to measure the contact state.

Switch threshold (FS 2000 setting):

Conduction threshold (L ->H): 6 V (1200 bits).

Turn off threshold (H ->L): 3 V (600 bits).

LB threshold (fault): ≤ 0.5 V (100 bits).

LS threshold (fault): ≥ 8.4 V (1680 bits).

4.2.2 Mechanical contact connections on digital inputs

Digital inputs can be connected to mechanical contacts for status monitoring. One set of 8 input power supplies (LS+) must be monitored by another digital input.

Switch threshold:

Conduction threshold:>12V (1200 bits).

Shutdown threshold:<10 V (1000 bits).

LB threshold (fault):<2 V (200 bits).

LS threshold (fault): Power supply voltage -1.1 V (1100 bit).

5. Communication capability and network interface

The F35 controller integrates powerful communication capabilities, supports safety related SafeEthernet, and multiple standard fieldbus protocols.

5.1 Ethernet Communication

Integrated switch: The controller integrates a secure Ethernet switch internally for connecting remote I/O or PADT (programming and debugging tool).

Interface: 4 RJ-45 interfaces, supporting 10/100Base-T, automatic negotiation and automatic crossover.

Security protocol: SafeEthernet (Safety Related Communication).

Standard protocols: EtherNet/IP, OPC, Modbus TCP, SNTP, etc.

Network Port Allocation (UDP/TCP):

8000: SILworX programming and operation.

8001: Remote I/O configuration (ELOP II Factory).

8004: Remote I/O configuration (SILworX).

6010: SafeEthernet and OPC.

123: SNTP time synchronization.

5.2 Fieldbus interfaces (FB1, FB2, FB3)

F35 provides three D-sub connectors for installing fieldbus modules:

Supported protocols: PROFIBUS DP Master/Slave, Modbus Master/Slave, INTERBUS Master, RS485, RS232.

Note: The INTERBUS protocol is not supported in SILworX.

6. Installation, wiring, and environmental conditions

6.1 Environment and Mechanical Installation

Operating Temperature

F35 01: 0…+60 °C

F35 011/012: -20…+60 °C

Installation method: 35 mm DIN rail installation or mounting plate (F35 012).

Protection level: IP20. If installed in Zone 2, it must be installed in a cabinet with a protection level of at least IP54 and comply with EN 60079-15 requirements.

ESD protection: Operators must have ESD protection knowledge and wear anti-static wristbands.

6.2 Wiring specifications

Digital Input (DI): Supports mechanical contact connections. Each group of 8 inputs shares one power supply (LS+). The maximum length of the line is 300 meters.

Digital output (DO): Pay attention to the load connection. For single pole switch output, the corresponding channel group negative pole (L -) connection must be used to ensure effective internal protection circuit.

Analog Input (AI): Shielded twisted pair cables with a maximum length of 300 meters must be used. Unused analog inputs must be short circuited. To measure voltage, the internal resistance of the external source needs to be considered, and the channel needs to be terminated by a 10 k Ω resistor.

Counter: The maximum wire length is 500 meters, and shielded twisted pair cables must be used.

7. Diagnosis, LED indication and maintenance

7.1 LED Indicator System

The F35 controller is equipped with rich LED indicators on the front for quick diagnosis of system status:

RUN (green): The device is in RUN state and executing user programs normally.

ERROR (red): An internal fault (hardware, software, or watchdog timeout) has been detected, entering the ERROR STOP state.

PROG (yellow): Loading new configuration.

FORCE (yellow): The forced function has been activated.

FAULT (yellow): The loaded configuration is defective.

I/O LEDs (yellow): indicate the activation status of each input/output channel.

7.2 Maintenance Measures

Regular testing: It is recommended to recalibrate the analog input every 10 years. Conduct a Proof Test every 10 years, referring to the Safety Manual (HI 800 023 E).

Operating System Update: HIMA continuously improves the operating system and recommends using the latest version.

Fault handling: For OS versions 6.42 and above, if a fault is detected during self inspection, the device will restart; If the malfunction occurs again within one minute, the device will enter the STOP_INVALID state.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc