GE DS200TBQCG1AAA Analog Termination Board

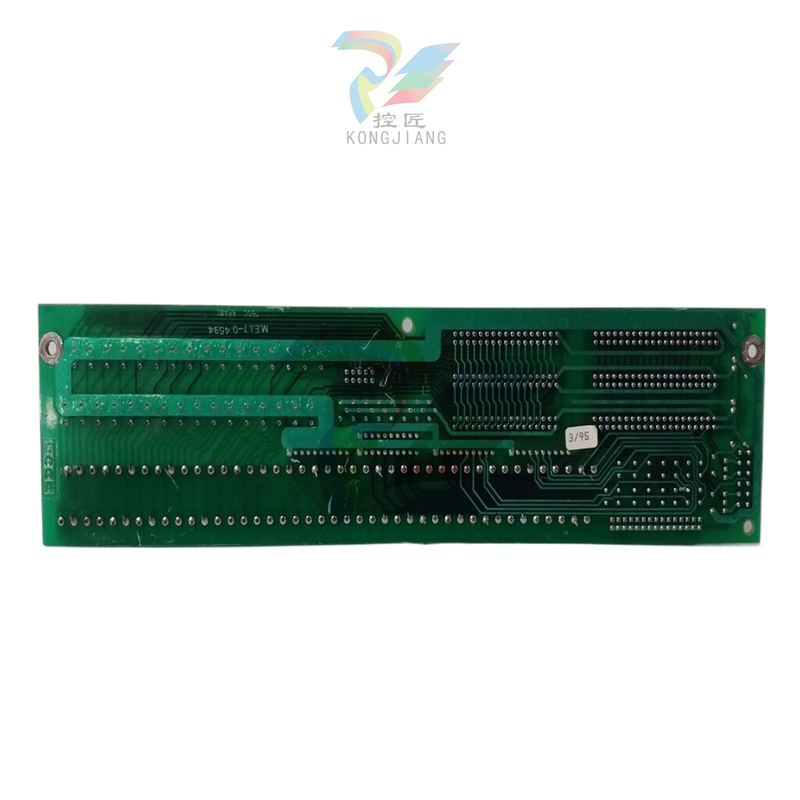

GE DS200TBQCG1AAA Analog Termination Board

DESCRIPTION

This DS200TBQCG1AAA General Electric printed circuit board is a Mark V Turbine Control System Series product with a normal assembly version but a complicated intended functionality within said Mark V Series, as alluded to earlier. This DS200TBQCG1AAA printed circuit board is referred to by its official functional description as an Analog Input Milliamp Input/Output Termination Module or Analog Input Milliamp I/O Termination Module for short, although some fringe General Electric and Mark V Series instructional manual materials may condense its functional description to that of a GE RST Analog Termination Board.

Main Characteristics

Wiring Terminals:

Features 2 terminal blocks, each containing 83 signal line terminals for connecting external analogue signal sources.

Jumper settings:

Contains 15 jumpers for modifying the behaviour of the board to meet the exact requirements of drive operation.

Jumpers can be easily moved from the default position to an alternate position for easy configuration and adjustment.

Connectors:

Equipped with three 40-pin connectors and three 34-pin connectors for interfacing with other devices and systems.

Signal Processing Capability:

Supports processing of milliamp input signals and LVDT (Linear Variable Differential Transformer) input signals.

Capable of receiving analogue signals from sensors and converting them to digital signals for further processing.

Reliability and Stability:

The use of high-quality electronic components and advanced production processes ensures that the board can operate stably in a variety of harsh environments.

After rigorous testing and verification to meet the reliability and stability requirements of industrial automation control systems.

Application Scenarios

DS200TBQCG1AAA analogue terminal board is widely used in various industrial automation control systems, such as electric power plants, electric power transmission systems, electric power distribution systems and industrial automation processes involving electric power control. It can be used to receive and process analogue input signals from generators, steam turbines, boilers and other equipment to achieve monitoring and control of industrial processes.

Installation and Configuration

Installation:

Install the analogue terminal board correctly into the designated slot or rack to ensure a firm and reliable connection.

Connect external signal sources and connectors according to the wiring diagram to ensure correct signal transmission.

Configuration:

Configure the jumpers according to the actual needs to meet the requirements of drive operation.

The board can be parameterised and calibrated by software tools to ensure its normal operation.

Technical Support and Service

GE provides comprehensive technical support and services for DS200TBQCG1AAA analogue terminal board. Users can obtain relevant technical documents, product manuals, wiring guides and other information through GE's official website, customer service hotline or authorised agents. GE also provides professional training and after-sales service to ensure that users can properly use and maintain the analogue terminal board.

Precautions

Before use, please read the product manual and wiring guide carefully to ensure the correct connection and configuration of the analogue terminal board.

During use, please pay attention to keep the working environment temperature and humidity of the analogue terminal board within the specified range to avoid moisture or overheating.

Regularly check the wiring and connections of the analogue terminal board to ensure that the connections are firm and reliable.

If you find any malfunction or abnormality of the analogue terminal board, please contact GE's customer service team or authorised agents for repair or replacement.

APPLICATIONS

• Simulation

• Instrumentation

• Industrial control

• Process control and monitoring

• Factory automation

• Intelligent networked PLC controllers

• Automated test

• Data acquisition

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-