Baldor Reliance Full Horsepower DC Motor Comprehensive Guide: From Technical Specifications to Industrial Application Selection

Baldor Reliance Full Horsepower DC Motor Comprehensive Guide: From Technical Specifications to Industrial Application Selection

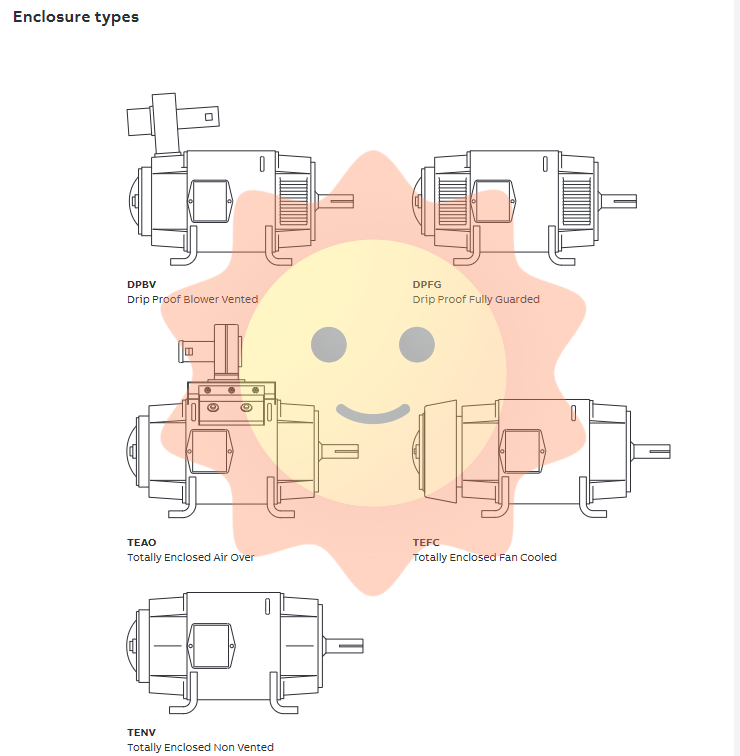

1. Shell type and motor classification

Baldor Reliance DC motors offer a variety of housing designs to meet different environmental conditions and cooling needs:

DPFG (Drip Proof Fully Guarded): Suitable for places with relatively clean environments. This design allows for free air circulation while preventing liquid or solid particles from dripping in at angles less than 15 degrees.

TEFC (Completely Enclosed Fan Cooled): prevents free exchange of external air with the interior of the motor, and uses the built-in cooling fan for heat dissipation. This is the most universal industrial motor design, suitable for dusty and humid environments.

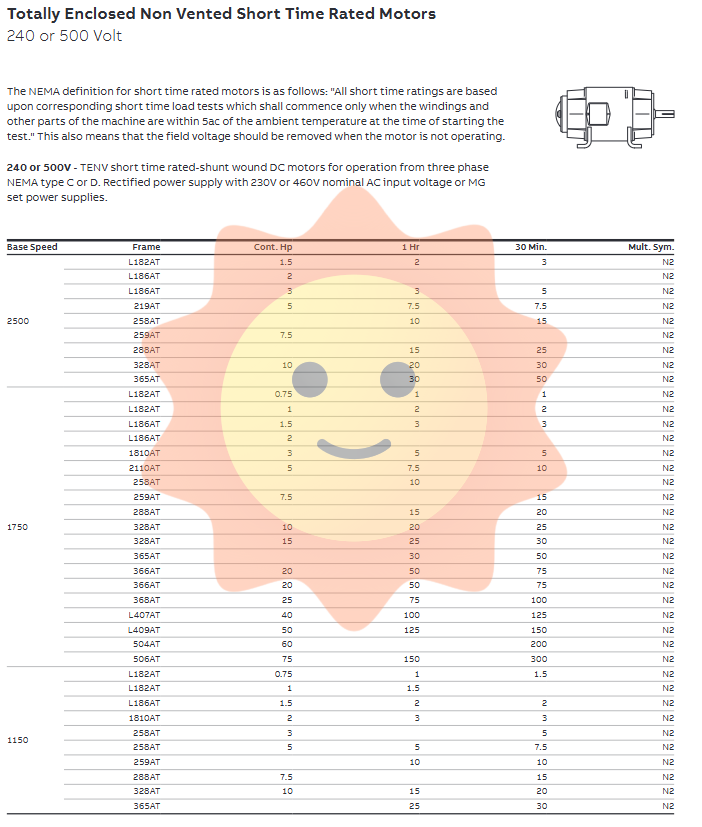

TENV (Completely Enclosed Non Ventilated): Fully enclosed design without fans. These types of motors are typically designed for low-speed constant torque operation or for situations that rely on external cooling systems such as TEAO.

DPBV (Drip Proof Blower Vented): achieves a wider speed range and higher power output through forced ventilation. Note: The base price of many DPBV models may not include a hair dryer and needs to be purchased separately.

TEAO (Completely Enclosed Air Over): Designed specifically for installation in systems with external forced ventilation, such as extruder barrels or ventilation control cabinets. The motor casing itself does not contain a fan, but relies on external airflow for cooling.

XP (Explosion Proof): An explosion-proof motor that meets UL standards and is suitable for Class I and II (Groups C, D, E, F, G) hazardous locations. This type of motor comes standard with a thermal protection device.

2. Core performance parameters and electrical characteristics

Voltage and winding configuration

Baldor Reliability DC motors support multiple standard voltage levels to meet different power requirements:

Armature voltage: Standard configurations include 180V, 240V, and 500V DC.

Magnetic field voltage: Corresponding to different armature voltages, standard configurations of 100/200V, 150/300V, or 120/240V are provided.

Power code: The motor is designed for specific rectifier power sources, such as NEMA type C (for 240V/500V) or NEMA type K (for 180V).

Insulation system and temperature rise

Standard insulation: using Class H insulation system, but operating under Class F temperature rise. This configuration extends the insulation life and provides a safety margin.

Temperature rise level: Standard motors provide Class F temperature rise (1.0 service factor). For heavy-duty applications such as paper mills, the Class B temperature rise option is available, allowing operation at higher loads (typically providing a service factor of 1.15 at Class B temperature rise).

VPI insulation: For large frames (360AT-500AT) and special requirements, a vacuum pressure impregnation (VPI) insulation system is provided to enhance moisture resistance and chemical corrosion resistance.

speed regulation range

Constant torque: Many models support constant torque operation below base speed, and some models can reduce it to 20% of base speed (through weak magnetic speed regulation).

Weak magnetic speed regulation: By reducing the magnetic field strength, the motor can operate at a speed higher than the base speed. The weak magnetic range is a key parameter in selection, and some applications (such as coiling machines) may require special weak magnetic range expansion.

3. Special application specific motors

For specific industrial environments, Baldor Reliance offers specially designed motor models:

3.1 Paper Mill Service Motor

The paper mill environment is humid, corrosive, and requires high overload capacity.

Features: Equipped with shaft grounding brushes to prevent bearing damage due to shaft current; Use splash guard and transparent handhole cover for easy inspection.

Overload capacity: Class B temperature rise motors are designed to withstand 200% load for one minute at base speed and below; Class F temperature rise motors can withstand 150% load for one minute.

Cooling options: Provides independent ventilation (DPG-SV) or forced ventilation with integrated blower (SPG-FV) options.

3.2 Extruder motor

Specially designed for plastic and rubber extruders, often in high-temperature environments.

High temperature adaptation: designed for ambient temperatures up to 65 ° C.

Cooling system: Adopting a forced ventilation design, equipped with motor-driven hair dryers and high flow washable filters to ensure a continuous supply of cooling air.

Structure: Adopting a fully enclosed commutator design to prevent pollutants from entering.

3.3 Cranes and Handling Motors

Low inertia design: provides fast acceleration and deceleration capabilities for handling equipment in the wood processing industry.

Configuration: Typically designed for DPBV, with a 500V armature and a 150/300V magnetic field.

4. Key selection modifications and accessories

To meet specific installation environments and mechanical connection requirements, Baldor Reliability offers a wide range of modification options (Mod Express):

4.1 Mechanical and structural modifications

Shaft seal:

Inpro ® Shaft Seal: A labyrinth non-contact seal used to prevent the intrusion of liquids, solids, vapors, and mud.

Forsheda ® Shaft Seal: Used to prevent oil and dust contamination.

Lip Seal: Used in situations where oil pressure exists (such as connecting gearboxes).

Installation options:

Base type: Provides sliding base (for belt tension adjustment), base guide rail, and bottom plate.

Vertical installation: Suitable for vertical installation configuration of DPFG and TEFC motors, equipped with anti drip cover and lifting device.

C-Face/D-Blade: Provides NEMA standard C-face or D-face installation methods, compatible with gearboxes.

4.2 Thermal protection and monitoring

Thermostat: Installed on the intermediate coil to provide overheating protection. The options include high temperature limit thermostat and low temperature alarm thermostat.

PTC Thermistors: Smaller in size than thermostats, providing more accurate temperature monitoring and typically requiring external control modules for use.

Resistance Temperature Detector (RTD): Provides analog signals for continuous temperature monitoring, used in conjunction with instruments provided by customers.

Space heater: prevents condensation of the motor when it is stopped, usually used outdoors or in high humidity environments.

4.3 Feedback and Control Equipment

Encoder: Provides multiple feedback options, including:

Hollow Shaft Encoders: Magnetic or optoelectronic, maintenance free design.

Coupled Encoders: Suitable for NEMA C-face or PY flange installation through coupling.

Explosion Proof Encoders: Certified for use in hazardous locations.

Speed generator: Analog or digital output, used for speed feedback.

Rotary Transformer: Provides robust position and speed feedback.

4.4 Braking System

Disc brake: spring set, electrically released brake.

Installation: It can be installed on the commutator end (C side) or the opposite shaft extension end.

Manual release: Standard manual release device for easy maintenance.

4.5 Environmental Enhancement

Harsh environment: The "Dirty Duty" option offers epoxy primer, anti-corrosion hardware, and sealing gaskets, suitable for the paper or chemical industry.

Outdoor/Weather resistant: including special paint system, double sealed bearings, and shaft oil slinger.

Marine applications: Compliant with IEEE 45 standard, suitable for under deck services.

5. DC generator

In addition to motors, the catalog also includes DC generators used for cranes and handling magnets:

Enhance magnetic generator: 230V DC output, compound excitation design, with droop voltage characteristics to ensure load stability.

Universal DC Generator: Provides 120V or 250V output, suitable for independent power systems.

Conclusion

The Baldor Reliability full horsepower DC motor series provides highly reliable solutions for industrial motion control with its modular design, powerful insulation system, and deep customization capabilities for specific applications such as papermaking, extrusion, and hazardous areas. By selecting appropriate housing types (such as DPFG, TEFC, DPBV) and incorporating necessary modifications (such as shaft seals, heaters, or explosion-proof feedback), engineers can ensure that the motor can perform at its best under any operating conditions.

KPD-KG420-20 4x20 character/graphic display, serial interface

KPD-KG420-30 4x20 character/graphic display, 12 function keys, serial interface

KPD-TS03M-10 3.9" monochrome touch screen with serial interface

KPD-TS05M-10 5.6" monochrome touch screen with serial interface

KPD-TS05C-30 5.6" color TFT touch screen with serial interface

KPD-TS05C-30E 5.6" color TFT touch screen with serial interface and Ethernet

KPD-TS10C-30E 10" color TFT touch screen with serial interface and Ethernet

KPD-TS12C-30E 12.1" color TFT touch screen with serial interface and Ethernet

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor