Baldor Reliability NEMA Super-E Ultra High Efficiency Motor Comprehensive Guide

Baldor Reliability NEMA Super-E Ultra High Efficiency Motor Comprehensive Guide: Technical Specifications, Product Line, and Application Analysis

1. Life cycle cost analysis: why choose ultra efficient motors?

In the process of motor selection, the initial purchase price often receives high attention, but in the long run, this is only the tip of the iceberg. According to Baldor Reliance data, the energy consumption cost of a 75kW (100 horsepower) motor accounts for the vast majority of the total cost of ownership (TCO) during its 20-year continuous operation life cycle, while the original purchase price is almost negligible.

NEMA Super-E ® The original intention of motor design is to maximize the return on investment. By providing the industry's highest overall efficiency level - reaching or exceeding NEMA Premium ® Energy efficiency standard - Super-E motors can significantly reduce industrial electricity consumption. For most industrial processes, upgrading motor systems (including the use of variable frequency drives (VFDs)) can help businesses save up to 33% of energy expenses on average, which not only reduces operating costs but also complies with increasingly strict environmental regulations.

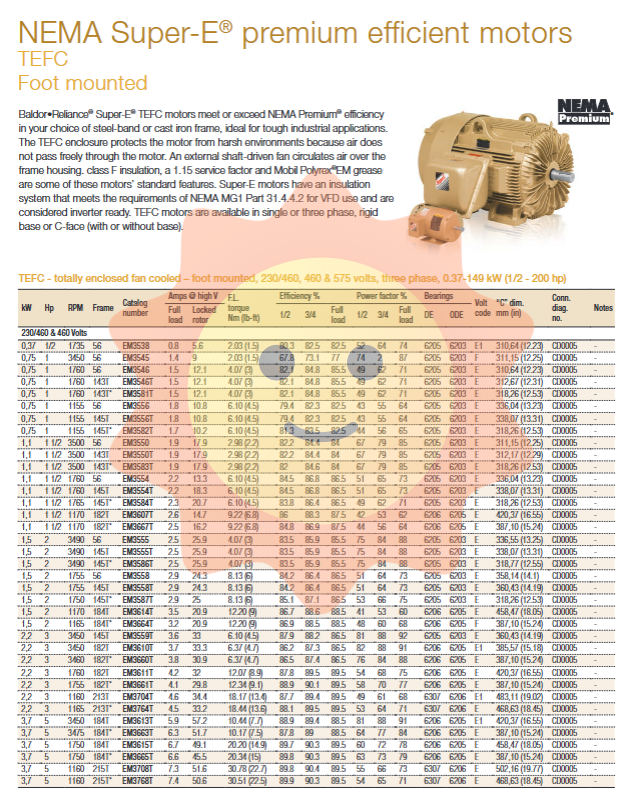

2. TEFC fully enclosed fan cooled motor series: suitable for harsh industrial environments

The fully enclosed fan cooling (TEFC) design is the most commonly used protection level in industrial applications, which can prevent external dust, moisture, and pollutants from entering the interior of the motor. The Baldor Reliability Super-E series offers three main levels of TEFC motors to meet different levels of environmental harshness:

2.1 EM/QE: General Industrial Grade

This is the standard model of the Super-E series, suitable for general industrial use.

Machine base range: 143T to 449T.

Insulation system: Adopting an insulation system with a heat resistance level of Class F, a temperature rise limit of Class B, and providing a service factor of 1.15.

Inverter ready: The insulation system meets NEMA MG 1 Part 31.4.4.2 standards and can withstand the peak voltage generated by the inverter without the need for additional reactors.

2.2 ECP/EXE: Heavy duty/harsh working condition level

For applications that require stronger chemical resistance and protection against harsh weather conditions, the ECP (Extreme Chemical Protection) model is the ideal choice.

Enhanced protection: Made of cast iron machine base and end cover, with sealing components at the joint between the end cover and the machine base.

Anti corrosion coating: The casting surface is coated with two layers of epoxy primer and topcoat, which meet the 96 hour salt spray test requirements under ASTM B117-90 standard.

Sealed bearings: Both the non drive end (ODE) and the drive end (DE) are equipped with V-ring shaft seals, and larger models are also equipped with automatic grease discharge devices.

2.3 841XL: Extreme working condition level

For critical applications that suffer significant losses due to downtime, the 841XL motor exceeds the requirements of the IEEE 841-2001 standard.

Ultra long lifespan: Provides a 5-year limited warranty (standard model is 3 years).

High precision bearing protection: equipped with Inpro/Seal ® VBX or VBXX bearing isolators thoroughly prevent grease leakage and contamination from entering.

Low vibration standard: The vibration level has been rigorously tested and accompanied by documentation, far below the standard requirements.

3. ODP launches anti drip motor series: an economical choice for clean environments

Turning on the anti drip (ODP) motor allows air to flow freely through the winding, providing excellent heat dissipation performance and making it the best choice for relatively clean and weather protected environments.

3.1 Standard ODP Series

Power coverage ranging from 1 to 300 horsepower (0.75-224 kW), available with steel strip or cast iron base.

Features: Similar to the TEFC series, ODP motors also come standard with Mobil Polyrex ® EM grease and F-grade insulation system.

Applicability: Suitable for traditional fan, water pump, and conveyor belt applications.

3.2 Small Motor Rule Series

In order to comply with the 2010 regulations of the US Department of Energy (DOE) on small motors, Super-E provides an ODP version for small power applications.

Power range: 1/4 to 2 horsepower (single-phase) and 1/4 to 3 horsepower (three-phase).

Compliance: Fully meets DOE's average efficiency requirements while retaining the reliability of the Super-E brand.

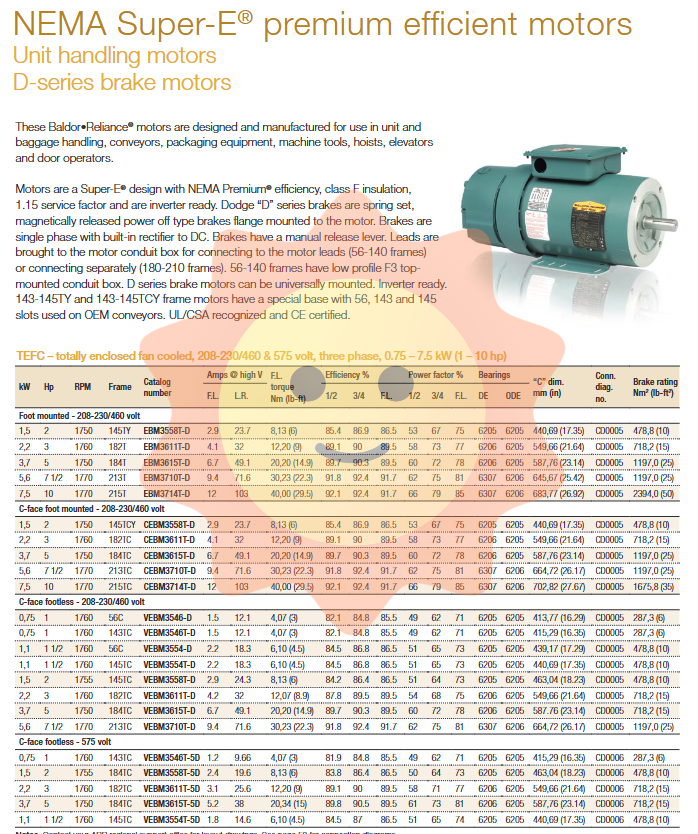

4. Special application specific motors

In addition to standard industrial motors, the Super-E series also offers deeply customized designs for specific application scenarios:

4.1 Closed coupled pump motor

AEGIS ® Grounding ring: This is a key characteristic in pump applications. Internally installed AEGIS ® The bearing protection ring can effectively prevent bearing damage due to shaft current, which is particularly important for pump systems using variable frequency drives.

Structural features: Equipped with enlarged ball bearings and a locked drive end structure to minimize end clearance to the greatest extent possible.

Specifications: Available in TEFC and ODP versions ranging from 3 to 20 horsepower (2.2-15 kW).

4.2 Vertical P-Base Motor

Application scenario: Specially designed for deep well pumps or vertical pumps in chemical, petroleum, refining, and wastewater treatment industries.

Thrust capability: designed to withstand axial thrust loads.

Material: Cast iron base with corrosion-resistant epoxy coating and equipped with shaft seal at the shaft end.

4.3 HVAC fans and blower motors

Silent design: The dynamically balanced rotor significantly reduces vibration and operating noise, making it ideal for HVAC applications.

Installation flexibility: The design supports installation in any position, and all machine bases are equipped with lifting lugs.

Optional protection: Some models have integrated AEGIS internally ® Bearing protection ring, suitable for air conditioning systems using VFD.

5. Core technical characteristics and lubrication

5.1 Advanced lubrication system

Bearing failure is the primary cause of mechanical failures in motors. Baldor Reliability Super-E series motors come standard with Mobil Polyrex ® EM polyurea grease is currently one of the most high-performance motor greases on the market.

Extended lifespan: In tests up to 176 ° C (350 ° F), its lubrication lifespan is more than four times longer than other polyurea greases.

Anti shear and anti water washing: Even under mechanical shear force or saltwater erosion, it can maintain excellent stability and provide rust and corrosion protection.

5.2 Inverter ready insulation

All Super-E motors (including TEFC and ODP) are equipped with a 200 ° C inverter peak insulation system.

Inter phase insulation: provides additional inter phase insulation protection.

Halo test: Meet the corona test standards of NEMA Part 31.4.4.2 to ensure long-term reliability under frequency converter power supply.

5.3 Dimensions and Installation

The motor offers a wide range of installation configurations:

Base installation: Standard rigid base.

C-face installation (NEMA C-face): suitable for directly connecting reducers or pumps, divided into two types: with base and without base.

F2 installation: Suitable for specific mechanical layouts.

6. Conclusion

ABB Baldor-Reliance NEMA Super-E ® The Premium Efficient Motors series provides a complete motion control solution for the industry through its modular design, ultra-high energy efficiency performance, and specialized optimization for pumps, HVAC, and harsh operating conditions. From the perspective of reducing the full lifecycle cost of energy consumption to the patented bearing protection technology that enhances reliability, Super-E motors are undoubtedly the best investment choice for modern industrial enterprises pursuing excellent performance.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor