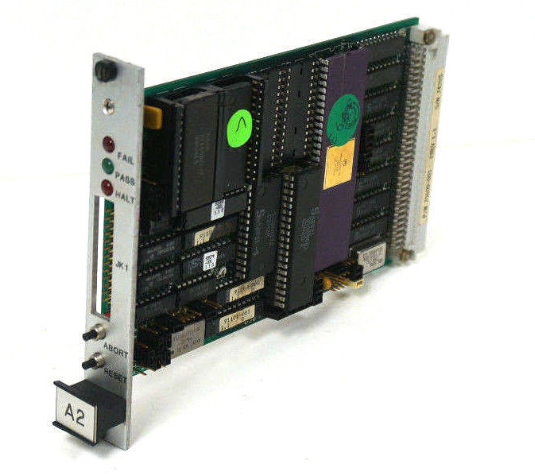

Horner APG HE693CALKIT simulation module

Horner APG HE693CALKIT calibration software is a computer program designed to support on-site and factory calibration of specific Horner APG simulation modules.

(2) Package composition

Each set includes: a floppy disk with calibration software, an RS-232 9-pin serial cable, a TTL to RS-232 converter, and an RS-232 ribbon cable with a 10 pin plug.

(3) Software operation requirements

Operating environment: Requires running on an IBM or compatible computer using DOS 3.1 or higher.

Hardware requirements: A text display is required and a serial port (COM1 or COM2) is used. The program defaults to using COM1.

(4) Module connection and preparation

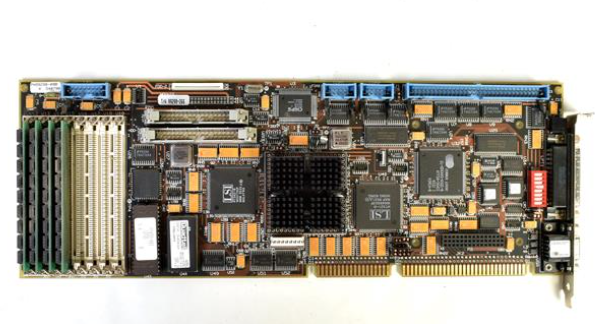

The simulation module needs to be connected to the selected serial port on the computer through an RS-232 cable, combined with a TTL-to-RS-232 converter or an RS-232 ribbon cable with a 10 pin plug (depending on the simulation module to be calibrated).

The module does not need to be configured in the PLC, but appropriate power must be provided for the bus pins of the module.

Product model calibration software Product model calibration software

HE693ADC405 adc4x5.exe HE693THM166 thm166.exe

HE693ADC410、HE693ADC420 adciso.exe HE693THM665、HE693THM666、HE693THM668 thm668.exe

HE693ADC406 adc406.exe HE693THM884(REV. A,B,C) thm884_1.exe

HE693DAC410、HE693DAC420 daciso.exe HE693THM884(REV. D,E,F,G,H,HX,J,K,L) thm884_2.exe、THM884cal.exe(Windows Version)

(2) Software startup (3.2)

1. Startup steps

Select the corresponding executable file from the floppy disk list (for example, calibrate HE693THM884 and select Thm884. exe).

Enter the corresponding command at the DOS prompt to run the calibration program: when using the COM1 port by default, enter "Thm884" and press "ENTER"; When using the COM2 port, enter "Thm884=C2" and press "ENTER".

To view command line switches and their instructions, enter "Thm884=?" at the DOS prompt and press "ENTER".

2. Screen Example (3.2.1)

After the program starts, the top of the screen will display the program name and version. Taking the THM884 thermocouple module calibrator (V2.04) as an example, the screen will display channel values, types, scales, zero points, and other information, as well as module models, channel quantities, hardware alarms, versions, and other parameters. At the same time, it will prompt the functions of each function key (F1-F9, Esc) (such as F1 calibration of J-type thermocouples, Esc exit, etc.).

3. Windows version software installation and operation (3.2.2, 3.2.3)

Installation: Load the floppy disk containing the THM884cal.exe (Windows version) installation file, locate and select the setup. exe file, follow the prompts to select the application file storage directory, and after installation is complete, you can use it.

Run: Find THM884cal.exe in the directory specified during installation, double-click the file to open the application; This version operates similarly to the DOS version. If you have any questions about the functionality, press the F12 key to access the help file.

(3) Process Overview (3.3)

Disable non-volatile random access memory (NVRAM): If the "disable" option is not provided, it will be automatically disabled. This step closes the old calibration constant and uses the default value for new calibration. The module needs to be reset to use the default value.

Disable PLC configuration: Make the module use default values (the module defaults to PLC configuration mode when powered on).

Initialization module: Execute after disabling PLC configuration.

Perform calibration: If it is a thermocouple module, you need to first select the calibration type. The software will prompt you for each step in the calibration process, and you need to follow the prompts.

Update NVRAM: Update the new default values to NVRAM.

Activate NVRAM: Enable the module to use the stored calibration constants the next time it is powered on.

Re initialize the module: Let the module re read the calibration and filtering constants from the NVRAM.

(4) Module specific calibration process (3.4)

The calibration steps and corresponding function keys for each module are as follows (some module examples):

1. Analog input module (3.4.1)

Taking HE693ADC406, HE693ADC405/415, and HE693ADC410/420 as examples:

Step Process Function Key

1. Disable NVRAM F5

Initialization module F6

3. Disable PLC configuration F8

Perform calibration (follow software prompts) F1

5 Update NVRAM (store new constants, select "Yes") F3

Activate NVRAM F4

7 Initialization module F6

2. Analog output module (3.4.2)

The calibration steps for HE693DAC410 and HE693DAC420 are the same as those for the analog input module. It should be noted that when calibrating the analog output module, the PLC must be in non operating mode.

3. RTD module (3.4.3)

HE693RTD600 and other models:

Step Process Function Key

1. Disable NVRAM F7

Initialization module F6

3. Disable PLC configuration F8

Perform calibration (follow software prompts) F1, F2, F3

5. Update NVRAM (store new constants, select "Yes") F5

Activate NVRAM F7

7 Initialization module F6

4. Strain gauge module (3.4.4)

The calibration steps for HE693STG883 and HE693STG884 are the same as those for the analog input module.

5. Thermocouple module (3.4.5-3.4.7)

HE697THM160, HE697THM260: Follow the same steps as the RTD module.

HE693THM166: The steps are consistent with the analog input module.

HE693THM406 and other models: The steps are consistent with the RTD module.

HE693THM884 (K-type+channel offset calibration): Use THM884_K.bat batch file, consisting of 15 steps, including module installation, power on, NVRAM disable/activate, PLC configuration disable/enable, calibration execution, offset setting and transmission, NVRAM update, module initialization, etc. Some steps require the use of function keys such as F1, F4, F5, F6, F7, F8, and finally remove the module after power off.

HE693THM894 (K-type calibration): Use the THM894_K.bat batch file, following the same steps as HE693THM884 (K-type+channel offset calibration).

Switch settings

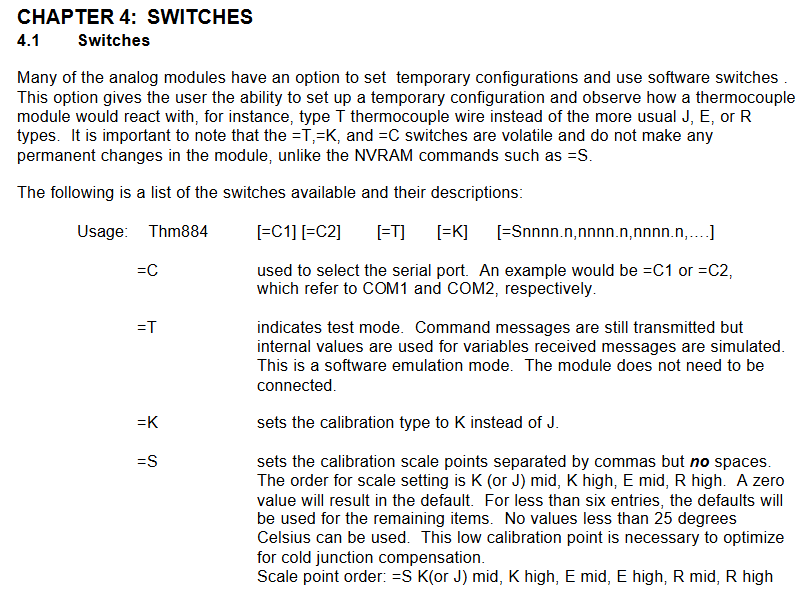

(1) Switch Description (4.1)

Many simulation modules can be temporarily configured and software switches can be used, such as observing the reaction of thermocouple modules using T-shaped thermocouple wires (rather than the commonly used J, E, R types); Please note that the=T,=K, and=C switches are volatile and will not cause permanent changes to the module, while commands such as=NVRAM (such as=S) will cause permanent changes. The switch format is "Thm884 [=C1] [=C2] [=T] [=K] [=Snnnn. n, nnnn. n, nnnn. n,...]", and the functions of each switch are as follows:

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc