TOSHIBA V200 Series PLC Programming and Safety Application Guide

Toshiba V200 Series PLC Programming and Safety Application Guide

Introduction: Overview of V200 Series PLC

Toshiba V200 series programmable logic controller (PLC) as a Windows based ® A universal industrial controller for the environment, widely used in fields such as mechanical control, process automation, and equipment monitoring. This series not only has powerful logical processing and computing capabilities, but also supports a rich instruction set and flexible expansion functions. Combined with the OIS PLUS series operating interface system, it provides users with a complete human-machine interaction and control system solution. This article will systematically review the safety specifications, instruction system, programming points, and system integration recommendations of the V200 series PLC based on the official user manual, aiming to provide engineers with a practical and comprehensive technical reference.

Chapter 1: Safety First - Installation, Operation, and Maintenance Standards

1.1 Safety Warning and Responsibility Definition

The manual emphasizes the importance of safe operation at the beginning. All installation, operation, maintenance, or scrapping of equipment must be carried out only after fully understanding all safety warnings and user guidelines in the manual. Warning signs are divided into three levels:

DANGER: Indicates that failure to follow instructions will immediately result in serious injury, equipment damage, or even death.

Warning: Indicates a dangerous situation that may cause serious injury or damage.

CAUTION: Indicates a situation that may result in minor or moderate injury or equipment damage.

In addition, the manual clearly states that any electrical or mechanical modifications without Toshiba's written consent will invalidate all warranties and third-party safety certifications (such as CE, UL, CSA) and may pose safety hazards.

1.2 Qualified personnel and job preparation

Only "qualified personnel" are allowed to install, operate, and maintain equipment. Qualified personnel must possess knowledge and skills related to electrical equipment and have received safety training. Before homework, it is necessary to:

Read the entire operation manual thoroughly.

Receive training on safe power on, power off, grounding, tagging and locking.

Familiar with the use of personal protective equipment.

Master basic first aid knowledge.

Upon arrival of the equipment, it is necessary to immediately inspect for any transportation damage. It is strictly prohibited to install or connect damaged equipment. When storing, it should be kept upright and placed in a ventilated, cool, dry, non corrosive gas and metal dust environment.

1.3 Installation environment and electrical connection requirements

Environmental requirements: The ambient temperature should be between 0 ° C and 50 ° C. Avoid installation in environments with vibration, high temperature, high humidity, dust, fibers, metal particles, explosive or corrosive gases, and electrical noise sources.

Installation specifications: Installation must comply with electrical safety standards such as NEC and OSHA. Adequate maintenance space and lighting must be provided.

Grounding and wiring: Key note: Metal conduits themselves cannot be used as grounding wires. Independent grounding cables must be used and laid together with power lines and control circuits in conduits. The CC marking point on the control terminal block must not be grounded. Good grounding is the foundation for preventing electric shock and suppressing electrical noise.

1.4 System Integration and Safety Interlocking

When integrating V200 PLC or OIS into large-scale systems, the system designer or integrator bears the primary safety responsibility:

Failure safety design: A mechanism must be designed to enable the system to switch to a safe state in the event of a malfunction.

Safety functions: Emergency stop, automatic restart settings, system interlocking and other safety functions should be fully utilized.

Unexpected startup warning: The PLC program may cause the motor to start unexpectedly. Must be familiar with the 'automatic restart' setting and post clear warnings next to the device.

Communication security: Serial communication control may fail or override local control, and redundant security mechanisms need to be designed.

Emergency stop design: It is strictly prohibited to use PLC units to perform emergency stop functions. Emergency stop must use independent hardware switches other than PLC, OIS, and frequency converter.

Program modification: Any modification of the PLC program must be approved by the system designer to prevent unintentional disruption of safety interlocks.

Chapter 2: Programming Core - Detailed Explanation of Ladder Diagram Instruction System

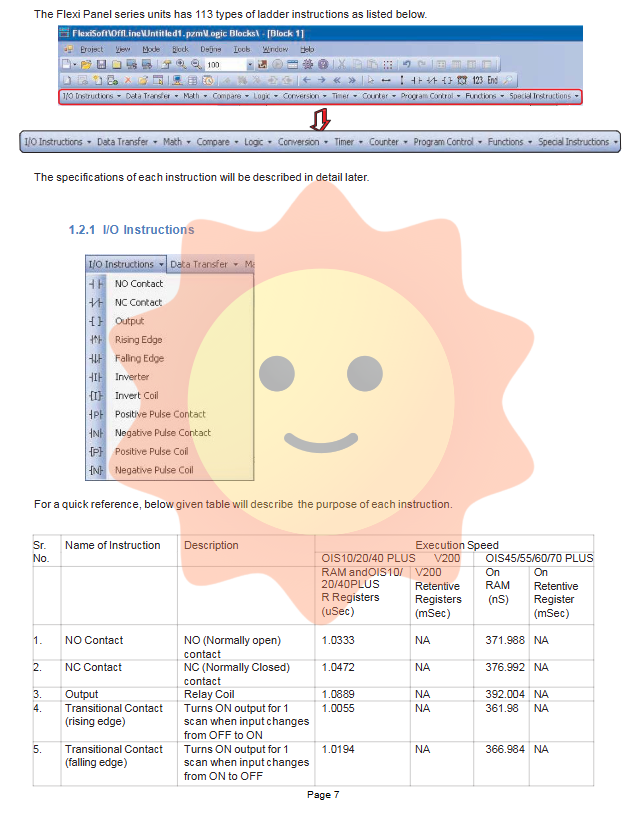

The V200 series PLC offers over 130 ladder diagram instructions, covering various aspects from basic logic to advanced functionality.

2.1 Instruction specifications and register types

The description of each instruction includes: expression, function, execution condition, operand, example, and comment. Special attention should be paid to register types and their impact on execution speed:

RAM registers, such as D, BW, MW, SW, T, C, have fast access speed.

Keep register: R register. In V200 and some OIS PLUS models, the R register is stored in EEPROM, which can hold data for more than 200 years, but the write operation limit is about 10 million times, and the access speed is slow (in milliseconds). In OIS10/40 PLUS, the R register is implemented by battery backed RAM, with the same speed as RAM.

Programming advice: Be cautious when using the R register as the target operand in scenarios that require frequent writing and are sensitive to speed.

2.2 Overview of Main Instruction Categories and Functions

I/O instructions: including basic logic components such as normally open/normally closed contacts, output coils, positive/negative jump detection, etc.

Data transfer instructions: such as MOV (word/double word transfer), data block transfer, data exchange, multiplexing/demultiplexing, etc., used for data transfer and reassembly between registers.

Arithmetic operation instructions: support addition, subtraction, multiplication, division of words, double words, floating-point numbers, as well as complex operations such as carry addition/subtraction, increment/decrement, logarithm, exponent, square root, etc.

Comparison instruction: Provides a complete set of comparison functions such as greater than, equal to, less than, etc., supporting signed, unsigned, doubleword, and floating-point formats respectively.

Logic and shift instructions: including logic and/or XOR, bit left and right shift, loop shift, shift register, etc., suitable for bit processing and sequence operations.

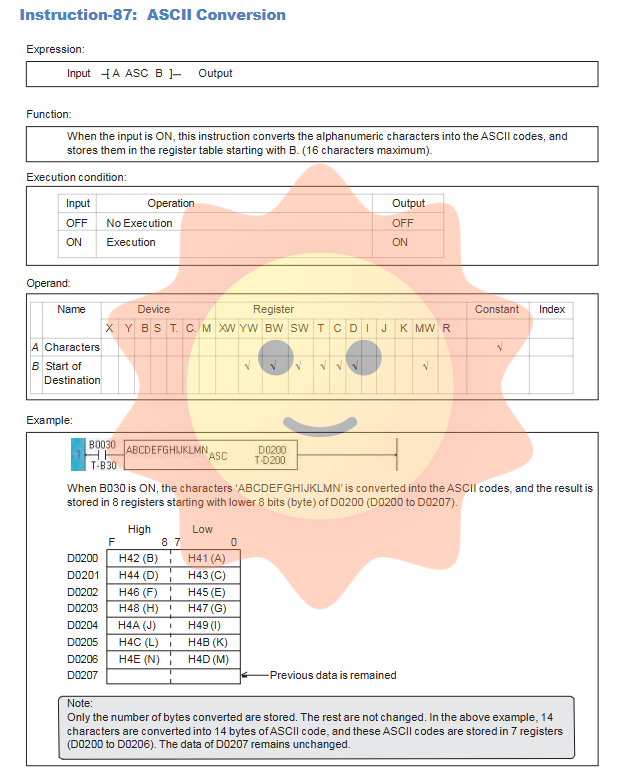

Conversion instructions: Implement hexadecimal and ASCII code conversion, absolute value, complement, seven segment decoding, BCD and binary conversion, integer and floating-point number conversion, etc.

Timer and Counter: Provides on delay, off delay, single trigger timer, as well as regular and reversible counters.

Program control instructions: subroutine call/return, loop (FOR-NEXT), main control (MCS/MCR), jump (JCS/JCR), interrupt enable/disable, etc.

Functional instructions: moving average, digital filtering, PID control (two algorithms provided), upper and lower limit amplitudes, maximum/minimum/average value lookup, function generator, etc.

Special instructions: including device/register reset, carry flag operation, encoding/decoding, bit counting, trigger, direct I/O, calendar setting and operation, etc.

2.3 Examples and Techniques of Key Instruction Applications

Data block operation: TMOV (table transfer) and TNOT (table fetch reverse transfer) instructions support source and destination region overlap and are suitable for sliding window processing of data buffers.

PID Control: The manual provides two types of PID commands. PID1 adopts pre differentiation real-time algorithm, with flexible parameter configuration; PID4 has a more organized structure, including dead zone settings and positive and negative action selection. Ensure that the PID instruction is executed once per scan cycle during use.

Step sequence control: By using the STIZ (initialization), STIN (step input), and STOT (step output) instruction sets, sequential flow control programs can be efficiently written, supporting parallel sequences, merging, and conditional branching.

Direct I/O: The Direct I/O instruction can immediately update all physical input/output states of a specified slot, suitable for interrupt programs or critical control segments that require extremely high real-time performance.

Shift register: used to implement first in first out queue or bit sequence processing. Note that the shift input signal should use jump contacts to prevent shifting every scanning cycle.

Chapter 3: Practical Guide - Programming and System Debugging Suggestions

3.1 Programming Environment and Property Settings

V200 is programmed using Windows based software. When placing instructions, a "Properties" docking window will appear on the right side of the software, allowing users to dynamically adjust the data type (signed, unsigned, floating-point) and data length (word, doubleword) of the instruction. This greatly increases the flexibility of programming.

3.2 Error Handling and Flag Bit

Instruction Error Flag (ERF): Typically the system flag S0034. Set when operations such as zero division or data format errors occur. The user program can reset it through the RST S0034 instruction.

Carry flag (CF): S0. Used for determining the results of carry operations and shift/rotate operations, which can be explicitly controlled through SETC and RSTC instructions.

Watchdog Timer: The WDR instruction can be used to extend the scanning time monitoring cycle, preventing watchdog timeout reset due to program complexity.

3.3 Data Recording and USB Functionality

Some models support USB data recording and uploading function (LD-UPLD). This command can generate a CSV file of the historical records of a specified time period and a specified data group, and save it to a USB flash drive. Users need to configure parameters such as start/end time, group number, and file name, and monitor task execution through status registers.

Chapter 4: Summary and Best Practices

The Toshiba V200 series PLC is a comprehensive and highly reliable industrial control platform. Its successful application relies on strict adherence to safety regulations and a deep understanding of the instruction system.

Best Practice Summary:

Safety first: Always follow electrical safety regulations, implement comprehensive hardware interlocking and fail safe design.

Planning registers: Reasonably allocate RAM and EEPROM registers to balance speed requirements and data retention requirements.

Modular programming: Actively using subroutines to make the program structure clear, easy to debug and maintain.

Make good use of advanced features: flexibly apply instructions such as PID, shift register, step sequence, function generator, etc. to simplify complex logic.

Emphasize error handling: Check error flags after critical operations to enhance program robustness.

Documented modifications: Any program changes should be documented and saved together with the system documentation.

By systematically mastering the content described in this guide, engineers can fully unleash the potential of V200 series PLCs and build safe, efficient, and stable industrial automation control systems.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor