What are the core protection mechanisms of WOODWARD Vertex's anti surge control?

What are the core protection mechanisms of WOODWARD Vertex's anti surge control?

Applications

The Vertex control is designed to control and protect industrial sized axial or centrifugal compressors. This controller includes specifically designed algorithms and logic to start, stop, control, and protect industrial compressors driven by a stationary speed motors, variable frequency drive motors, or turbines. OEM qualified algorithms are used within the Vertex control for straight-through, isocooled, double flow, stand alone, and back-to-back compressor applications.

The Vertex controller is field configurable allowing users to configure/select the specific control algorithm required for the specific compressor loop and application. The control’s special stage-to-stage and performance controller decoupling logic allows stable control during normal compressor operation as well as during plant upsets, minimizing process over or undershoot conditions.

This purpose-built controller has the control, protection, and decoupling logic required for one or two recycle loop compressor applications. OEM qualified algorithms are used to ensure that proper start sequences are followed, proper and accurate compressor load calculations are used, and proper protection and recovery actions are performed.

Basic functionality includes:

Motor or Turbine Drive Interface Logic

Inlet Throttle Valve Control

Inlet Guide Vane Control

Recycle Valve(s) Control

Anti-Surge Control (1 or 2 Recycle Loops)

Performance Control (suction or discharge pressure or process flow)

Surge Anticipation Logic

Surge Protection Logic

Surge Recovery Logic

Load Sharing (Parallel compressors, up to five Trains)

Optionally users can apply Vertex controllers in simplex or dual-redundant controller configurations. When applied in simplex configurations, a single Vertex controller is used to control and protect the compressor. When applied in dual-redundant controller configurations, two Vertex controllers are connected together in a parallel fashion with one unit functioning as the system controller (SYSCON), and one unit functioning as the backup controller (BACKUP). With dual-redundant configurations, transfer from the SYSCON to BACKUP controller is performed automatically upon a SYSCON failure, or manually by an operator for system and transfer verification purposes.

In dual-redundant applications, depending on system design, anti-surge valve movement during SYSCON and BACKUP controller transfer can either be bumpless (no-movement) or up to ~80 milliseconds in the open direction. To ensure system up-time with dual-redundant applications either Vertex controller (SYSCON of BACKUP) can be repaired and or replaced with the compressor operating on-line normally.

For applications where the compressor’s anti-surge valve (ASV) stays closed for long periods of time, the Vertex includes a special on-line ASV test routine to test and verify valve movement with little or no effect on compressor or process operation. With this special ASV test routine plant operators can now verify ASV health and performance without reducing production levels or effecting system availability.

Designed to function as a plant DCS node the Vertex controller can be configured to interface with the plant DCS via hardwired inputs/output signals or serial or Ethernet communications. With the capability to monitor and control all compressor based functions (i.e. bearing temperatures, vibration levels, control oil levels, etc.) the Vertex controller is ideal for use as a cost-effective compressor control/protection as well as a plant DCS monitoring node.

Designed to replace old obsolete anti-surge controllers, the Vertex can be configured to function like these controllers but uses faster scan rates, improved surge anticipation logic, and one integrated package for all control functions (anti-surge control loop 1, anti-surge control loop 2, and performance control). Also, for load sharing function, no need for additional Master controller hardware.

Description

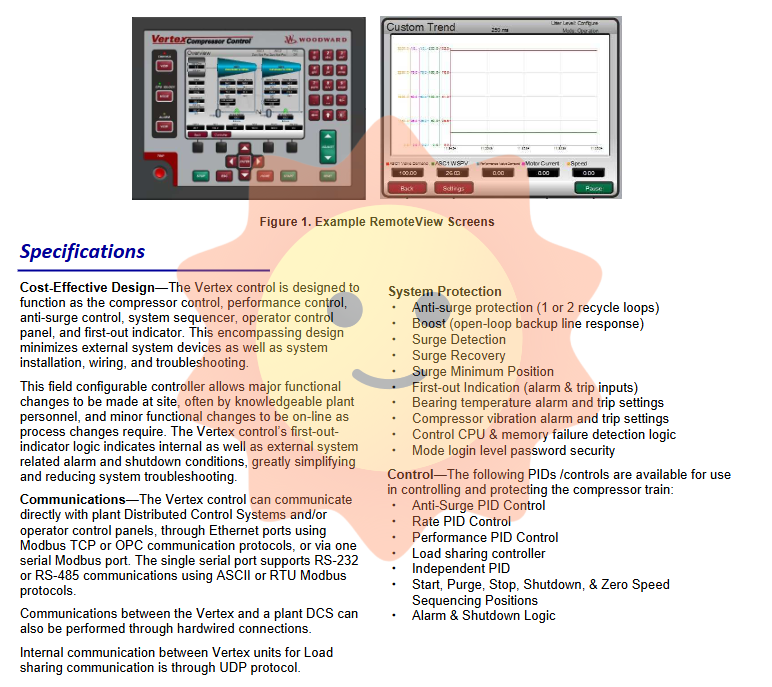

The Vertex control is packaged in an industrial hardened enclosure designed to be mounted within a system control panel located in a plant control room or next to the compressor. The control’s user-friendly front panel serves as both a programming station and operator control panel (OCP). This user-friendly front panel allows engineers to access and program the unit to the specific plant’s requirements, and plant operators to easily start/stop the compressor and enable/disable any control mode. The controller’s 8” graphical display allows operators to view actual and setpoint values from the same screen, simplifying compressor operation.

The control’s front panel serves as both a programming station and OCP. Password security is used to protect all unit program mode settings. The controller’s 8” graphical display allows operators to view actual and setpoint values from the same screen, simplifying turbine operation.

With dual-redundant Vertex controller applications, the front panels of both units function as redundant operator control panels and can be utilized to manage and monitor compressor operation.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc