Toshiba e-STUDIO Multifunctional Digital System Technical Specifications and Application Guide

Technical Analysis and Professional Application Guide for Toshiba e-STUDIO Multifunctional Digital System

Toshiba TEC has launched the e-STUDIO series of multifunctional digital multifunction printers, covering multiple models from desktop to floor standing, including black and white models (such as e-STUDIO2008A/5008A series) and color models (such as e-STUDIO2000AC/5005AC series and e-STUDIO5506AC/8508A series). These devices integrate copying, printing, and scanning, and some models even offer scanning/printing functions as an optional feature to meet diverse office needs. To help users and administrators better understand the potential of devices, this article will systematically review their core technical specifications, paper compatibility, device performance parameters, and a rich selection ecosystem.

1、 Detailed Analysis of Paper Specifications and Media Compatibility

The e-studio series is meticulously designed for paper compatibility, balancing standard sizes and non-standard media to ensure professional output quality.

1. Paper orientation and dimension labeling

The manual clearly distinguishes between portrait and landscape placement. For sizes such as A4, B5, LT (Letter), etc., they should be marked with "- R" when placed horizontally (such as A4-R). However, large sizes such as A3, B4, LD (Ledger), LG (Legal) only support horizontal placement, so the suffix "- R" is not added. The K format is the Chinese standard size.

2. Overview of compatibility of various paper series

The device supports various paper feeding methods, including standard paper boxes, large capacity paper feeders (LCF), envelope paper boxes, and bypass paper feeders. It is compatible with a wide range of media types and weights

Regular paper/recycled paper: generally supports 60-80 g/m ² (16-20 lb Bond).

Thick paper: Divided into multiple grades based on thickness, such as "Thickness 1" (106-163 g/m ²), "Thickness 2" (164-209 g/m ²), high-end models (such as 5506AC/8508A series) even support "Thickness 3" (up to 256 g/m ²), "Thickness 4" (up to 300 g/m ²).

Special media: including projection film (OHP), label paper (choose "Thick 2" type), index paper, cardstock, waterproof paper (Special 1/Special 2), copperplate paper (Special 3), and various commercial envelopes (such as COM10, Monarch, DL, etc.).

Important limitations and tips:

When using non-standard sizes, it is necessary to set them through 'Custom Paper'.

Envelope printing does not support back printing and automatic double-sided copying.

It is strongly recommended to use Toshiba recommended brands for projection film and label paper to prevent equipment malfunctions or poor printing results.

When installing an Inner Finisher or using specific thick paper, automatic double-sided copying may not be possible.

3. Recommended paper

Toshiba provides specific brand and weight recommendations for each type of medium, such as Mondi's TGIS Paper or Hammermill's TIDAL MP (80 g/m ²) for regular paper. Following the recommended paper is the key to ensuring print quality, reducing paper jams, and minimizing equipment wear.

2、 Core technical specifications and performance of the equipment

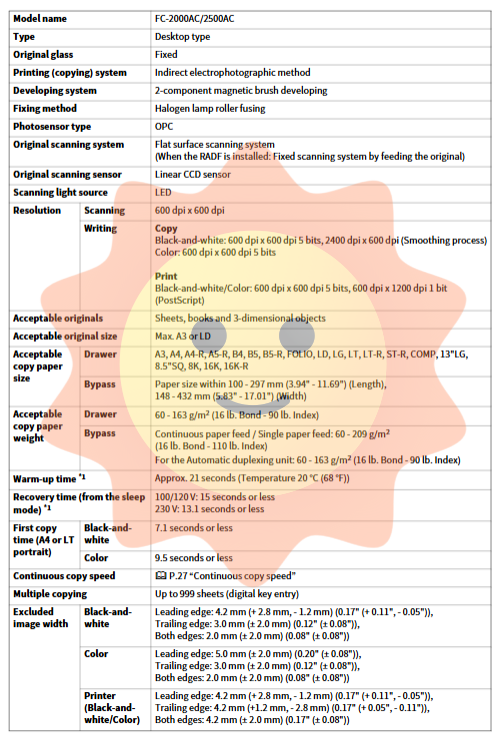

The e-STUDIO series adopts indirect electronic photography technology and is equipped with a two-component magnetic brush development system, which performs excellently in resolution, speed, and reliability.

1. Core imaging and processing system

Printing/copying system: indirect electronic photography method.

Development system: Two component magnetic brush development.

Fixing method: Some models use halogen lamp roller fixing (such as the 2000AC/2008A series), while new models mostly use external IH belt fixing (such as the 2505AC/5506AC series), which has higher energy efficiency.

Original manuscript scanning: Adopting a flat scanning system, equipped with linear CCD sensors and LED light sources. After installing the Reverse Automatic Document Feeder (RADF) or Double sided Synchronous Document Feeder (DSDF), automatic document scanning or synchronous scanning of double-sided original documents can be achieved.

Resolution: Scanning is done at 600 dpi x 600 dpi. The resolution of copying and printing varies depending on the model, with black and white copying supporting up to 2400 dpi x 600 dpi (smoothing), and color at 600 dpi x 600 dpi. The printing resolution can reach up to 3600 dpi (equivalent) x 1200 dpi (PostScript mode).

2. Performance indicators: preheating, homepage output, and continuous copying speed

Preheating time: about 20-24 seconds (in a 20 ° C environment), recovery from sleep mode takes about 12-16 seconds.

Homepage output time: The fastest black and white homepage can reach 3.6 seconds (such as e-STUDIO3508A), and the fastest color homepage can reach about 5.4 seconds (such as e-STUDIO7506AC).

Continuous copying speed: This is the core indicator for measuring equipment productivity. The speed varies significantly depending on the model, paper size, type, and paper feeder. For example:

E-STUDIO2000AC (color): A4 regular paper, with a paper box output speed of 20 pages per minute.

E-STUDIO5005AC (color): A4 regular paper, with a paper box output speed of up to 50 pages per minute.

E-STUDIO5008A (black and white): A4 regular paper, with a paper box output speed of up to 50 pages per minute.

E-STUDIO8508A (black and white): A4 regular paper, with a paper box output speed of up to 85 pages per minute.

Attention: When using thick paper, the continuous speed will decrease. When specifying the size of the bypass paper feeding, the speed is basically the same as that of the paper box. In low temperature environments, printing may pause for about 2 minutes to maintain quality.

3. Other key specifications

Scaling ratio: 25% -400% (increasing by 1%), when using RADF/DSDF, it is 25% -200%.

Paper supply capacity: standard paper box approximately 250-550 sheets (80 g/m ²), bypass tray approximately 100-120 sheets.

Power and Environment: Suitable voltage is AC 120V or 220-240V, normal working environment temperature is 10-30 ° C, humidity is 20-85% (no condensation).

Internal fonts: The device comes pre installed with a variety of PCL and PostScript fonts, including multiple languages and professional fonts such as Courier, Helvetica, Times New Roman, Arial, etc., to ensure the layout compatibility of document output.

Template function: Supports creating public and private template groups, for example, the e-STUDIO5008A series can have 1 public group and 200 private groups, with a maximum of 60 templates registered per group, improving batch job efficiency.

3、 Accessory ecosystem: Expanding device boundaries

The rich selection of accessories is the core advantage of the e-STUDIO series in adapting to complex workflows.

1. Optional document input options

Reverse Automatic Document Feeder (RADF) - MR-3031: Supports automatic submission of single and double-sided original documents, with a capacity of 100 pages (A4, 80g/m ²) and a scanning speed of over 50 pages per minute (600 dpi).

Double sided synchronous document feeder (DSDF) - MR-4000: a more high-end option with a capacity of 300 pages, supporting synchronous scanning of double-sided original documents, and faster scanning speed (up to 120 pages/minute for both sides).

2. Paper processing options

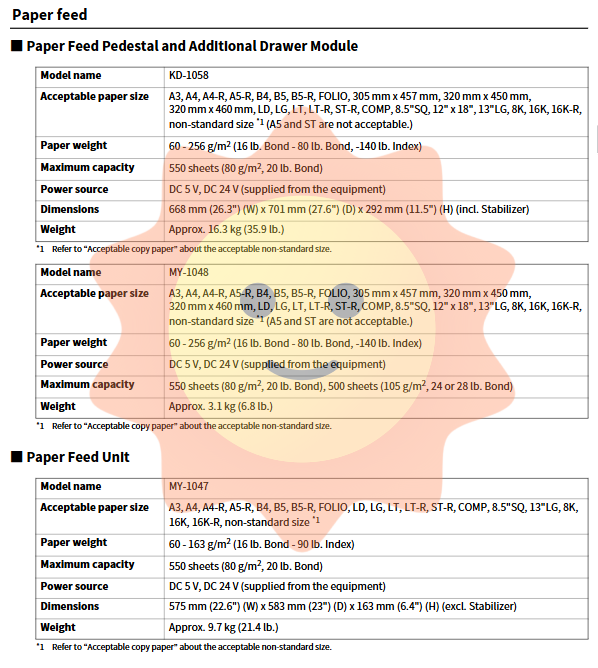

Paper box expansion: includes a paper box base (KD-1058), an additional drawer module (MY-1048), and a separate paper feeding unit (MY-1047), which can significantly increase the total paper feeding capacity.

Envelope paper box (MY-1049): designed for handling various sizes of commercial envelopes and specific sizes of paper.

Large capacity feeder: The internal large capacity feeder (such as KD-1059) can hold 2000 A4/LT papers. The external large capacity feeder (MP-2502A/L) has a larger capacity of up to 2500 sheets, making it suitable for departments with ultra-high printing volumes.

3. Output and post-processing options (binding and pagination)

This is the key to achieving automated document shaping. Optional accessories include:

Job Divider (MJ-5014/5015): Provides two stackers, top and bottom, to achieve job separation.

Bridge unit (KN-5005): connects the host and post-processing equipment.

Binding paginator: Various models, suitable for different host series.

Standard binding paginator (MJ-1109/MJ-11111): supports pagination, grouping, rotation pagination, binding pagination, magazine pagination and other modes.

Horseback binding and pagination device (MJ-1110/MJ-1112): In addition to the standard pagination function, it has added folding, center folding, and horseback binding functions, which can be used to make booklets.

Internal binding paginator (MJ-1042): Installed inside the device, it saves space and provides basic binding and pagination functions.

Punching Unit (MJ-6011/6105/6106 Series): Provides various punching specifications such as 2 holes, 3 holes, 4 holes, etc., and can be used in conjunction with different binders to achieve complete document filing preparation.

4. System function selection

Fax Unit (GD-1370): Supports A3 size transmission and reception, with 1GB of memory, compatible with Super G3 protocol.

Wireless LAN and Bluetooth module (GN-4020): Supports IEEE 802.11b/g/n standards and Bluetooth 3.0, enabling flexible mobile printing and connectivity.

Security and feature enablement kits, such as hard disk encryption kit (GE-1230), data overwrite enabler (GP-1070), IPsec enabler (GP-1080), etc., enhance enterprise level information security and management capabilities.

4、 Correspondence between binding mode and optional devices

Different combinations of binding paginators and punching units support different binding modes:

Non pagination, non binding, pagination, grouping, rotation pagination, magazine pagination: Almost all binders and job separators support them.

Binding pagination: It is necessary to install a binding pagination device or an internal binding pagination device.

Horseback binding and center folding: Only supported by the horseback binding paginator (MJ-1110/1112).

Punching: Additional punching units need to be installed.

Users need to choose the appropriate combination of post-processing equipment based on the desired output form of the finished product.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor