Baldor MicroFlex Servo Drive Professional Installation Guide

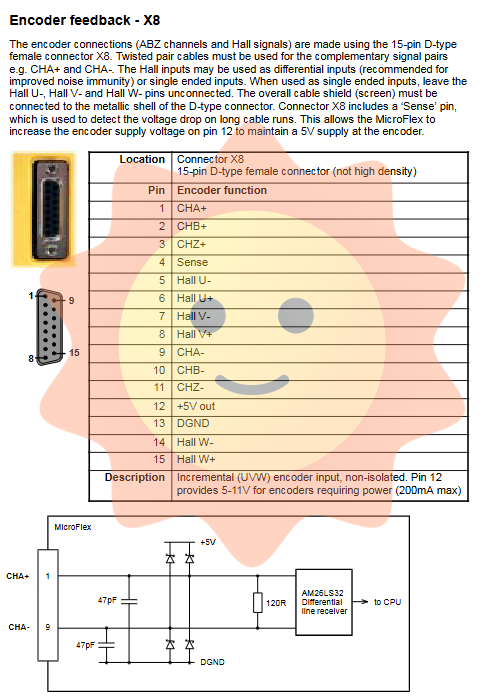

SSI encoder: connects differential data with clock signal. It is also required to use twisted pair cables and cable shielding layers for connection.

Wiring requirements: The feedback line must be wired separately from the power line; If parallel, maintain at least 76mm spacing; If crossing, it must be done at a 90 degree angle.

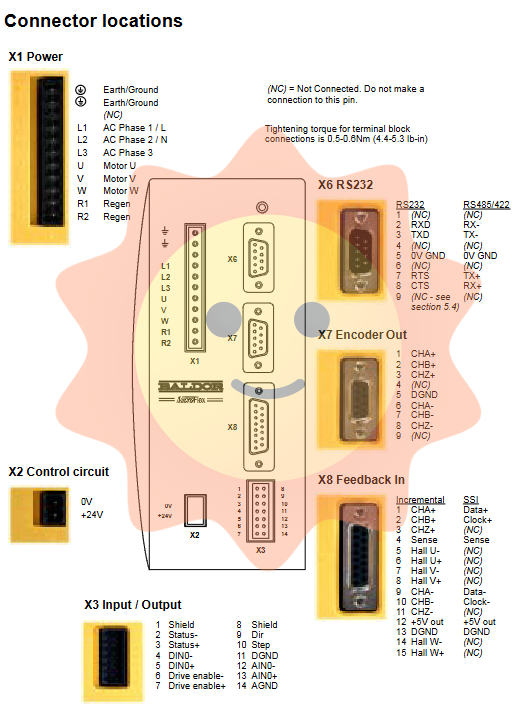

3.3 Encoder output

The driver provides encoder output signal (differential RS422) on connector X7 (9-pin D-type female plug). When using incremental encoder feedback, it replicates the input signal of X8; When using SSI feedback, it generates an analog encoder output.

4. Software configuration and debugging

4.1 WorkBench v5 configuration software

Install WorkBench v5 software using the included CD.

Connect the X6 connector of the driver to the PC via a serial cable (RS232).

After starting the software, use the "Commissioning Wizard" to guide the automatic tuning and configuration of the driver and motor combination. This process includes steps such as inputting motor parameters, performing automatic measurements, and alignment.

4.2 Further configuration and fine-tuning

Fine tuning tool: After completing the wizard, use this tool to manually fine tune the gain parameters of the position loop, velocity loop, and current loop for optimal performance.

Parameters tool: used to set a large number of parameters, such as scaling factors for feedback input, error handling actions, etc.

Other tools include editing and debugging tools for sending Mint commands, Scope tool for observing curves, and Spy window for monitoring important parameters of axes.

4.3 Control mode

MicroFlex can be configured as one of three basic control modes through WorkBench v5:

Current (torque) control: The driver acts as a torque amplifier, and the torque command comes from analog input or host software.

Speed control: The driver acts as a speed amplifier, with speed commands coming from analog inputs or host software.

Position control: The driver receives position commands through stepper and directional inputs as a positioning system.

5. Troubleshooting

The status LED on the front panel of the drive indicates its operating status:

Evergreen: The drive is enabled (operating normally).

Flash green: firmware download in progress.

Always red: The drive has been disabled, but there are no latch errors.

Flash red: There is a power base malfunction or error. The number of flashes represents the error code (e.g. 1 flash=DC bus overvoltage trip, 3 flashes=overcurrent trip, 7 flashes=over temperature trip, etc.).

Red green flashing alternately: undervoltage warning (no AC power supply), but no latch error.

If encountering communication problems, inability to enable, or unstable operation, check the 24V power supply, serial connection, drive enable input connection, and current/speed loop tuning. Detailed error code meanings and fault diagnosis steps can be found in the help file of WorkBench v5.

6. Summary of Specification Parameters

Input power supply: 115-230VAC, single-phase or three-phase.

Continuous output current: 3A, 6A, or 9A (different models).

Peak output current: 6A, 12A or 18A respectively, lasting for 0.5 seconds.

Working environment temperature: 0 ° C to 45 ° C (higher if derating is required), with a maximum relative humidity of 93%.

Feedback interface: Incremental encoder (maximum 8MHz) or SSI (Baldor motor, resolution up to 262144 lines/rev).

Communication interface: RS232 or RS485 (9600 to 57600 baud).

Protection level: IP00 (to be installed inside the control cabinet).

By following the detailed installation, connection, configuration, and troubleshooting guidelines mentioned above, users can ensure the safe, efficient, and reliable operation of the Baldor MicroFlex servo drive system.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor