Baldor MicroFlex Servo Drive Professional Installation Guide

Baldor MicroFlex Servo Drive Professional Installation Guide

1. Product Overview

Baldor MicroFlex is a multifunctional brushless servo drive that provides flexible and powerful motion control solutions for rotary motors and linear motors. Its core features include:

Single axis AC brushless drive: available in continuous current rated models of 3A, 6A, or 9A.

Wide power adaptability: directly connect to 115VAC or 230VAC single-phase power supply, or 230VAC three-phase power supply.

Diverse feedback support: compatible with incremental encoders or SSI (Synchronous Serial Interface) encoders.

Flexible control mode: supports current (torque), speed, and position (step and direction) control.

Intelligent configuration: equipped with Auto tuning wizard (including position ring) and software oscilloscope function, implemented through WorkBench v5 configuration software.

Rich I/O interfaces: including 2 optically isolated digital inputs (1 driver enable, 1 universal), 1 digital status output, and 1 universal analog input (± 10V).

Communication capability: Equipped with RS232 or RS485 communication interfaces according to the model, used for setup and diagnosis.

MicroFlex can be used in conjunction with various Baldor brushless rotary and linear servo motors.

2. Installation Guide

2.1 Mechanical installation and cooling

Environmental requirements: The drive must be permanently fixed indoors and only accessible to professionals using tools. The maximum altitude is 1000m, and the pollution level does not exceed Level 2 of IEC664.

Installation direction: The driver should be installed vertically on the back (i.e. opposite side of the panel), ensuring that it stands upright on a flat metal surface for easy cooling.

Cooling requirements:

3A model: It can operate naturally cooled at ambient temperatures ranging from 0 ° C to 45 ° C.

6A and 9A models: Output full rated current at an ambient temperature of 45 ° C and require forced air cooling (with wind flowing vertically from the bottom to the top of the drive). 45 ° C to 55 ° C requires derating for use.

If the cooling requirements are not met, it will shorten the product life and cause overheating tripping.

Installation spacing: The minimum spacing between drives or other devices should be maintained to ensure cooling efficiency. When arranged side by side, the distance should be at least 15mm, and when stacked up and down, the distance should be at least 90mm, and should be aligned up and down to promote air circulation.

Grounding: The grounding terminal at the top of the drive must be connected to a safety grounding point (star grounding point) through a conductor of at least 25A or three times the rated peak current (whichever is greater).

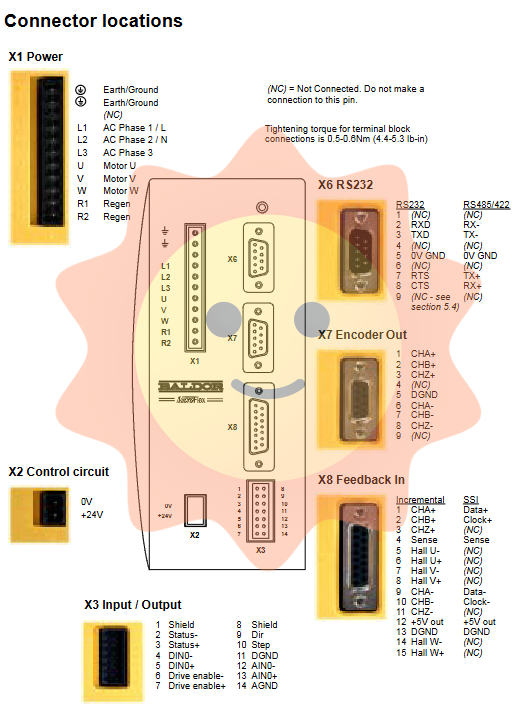

2.2 Power Connection

AC input power supply: Input through connector X1. The input voltage range is 105-250VAC (1 Φ or 3 Φ). Suitable circuit breakers or fuses must be installed, as well as EMC filters that comply with the CE directive.

Grounding/Safety: The permanent grounding point on the drive heat sink should be used as a protective grounding. The grounding terminal in connector X1 shall not be used as the main protective grounding, as it cannot guarantee to connect first and then disconnect.

Power outage protection: A circuit breaker must be installed at the input end of the AC power supply to safely disconnect the power supply when needed. After a power outage, the internal DC bus voltage of the driver needs to be discharged for a period of time (ranging from 83 seconds to 248 seconds depending on the model) before it can drop to a safe voltage (≤ 50VDC).

2.3 24V control circuit power supply

An independent, regulated 24VDC power supply must be connected to the X2 connector for powering the control electronics.

The power supply needs to have a continuous power supply capacity of 1A (typical startup wave current 4A).

This power supply should be isolated from the AC power supply and equipped with an independent fuse.

3. Motor and feedback connection

3.1 Motor connection

The motor power lines (U, V, W) are connected to the driver through connector X1. Be sure to ensure that the motor terminals are connected to the driver terminals (U, V, W) correspondingly, otherwise it may cause the motor to move uncontrollably.

The motor power line must use shielded cables, and the motor grounding should be connected to the driver grounding terminal.

According to safety regulations or application needs, a contactor (M-contactor) can be installed in the motor circuit to physically disconnect the motor winding. Before opening the contactor, the driver must be disabled at least 20ms in advance, otherwise it may be damaged.

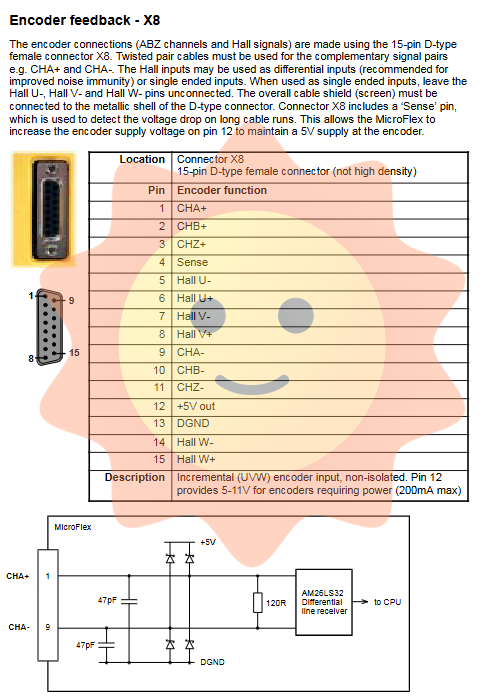

3.2 Feedback device connection

Feedback is connected through connector X8 (15 pin D-type female plug), supporting incremental encoders or SSI encoders.

Incremental encoder: Connect A/B/Z phases and Hall signals (if any). Differential signal pairs (such as CHA+and CHA -) must be connected using twisted pair cables. Hall signals can be used as differential inputs (recommended) or single ended inputs (when single ended, hang the Hall pin). The total shielding layer of the cable should be connected to the metal shell of the D-type connector.

SSI encoder: connects differential data with clock signal. It is also required to use twisted pair cables and cable shielding layers for connection.

Wiring requirements: The feedback line must be wired separately from the power line; If parallel, maintain at least 76mm spacing; If crossing, it must be done at a 90 degree angle.

3.3 Encoder output

The driver provides encoder output signal (differential RS422) on connector X7 (9-pin D-type female plug). When using incremental encoder feedback, it replicates the input signal of X8; When using SSI feedback, it generates an analog encoder output.

4. Software configuration and debugging

4.1 WorkBench v5 configuration software

Install WorkBench v5 software using the included CD.

Connect the X6 connector of the driver to the PC via a serial cable (RS232).

After starting the software, use the "Commissioning Wizard" to guide the automatic tuning and configuration of the driver and motor combination. This process includes steps such as inputting motor parameters, performing automatic measurements, and alignment.

4.2 Further configuration and fine-tuning

Fine tuning tool: After completing the wizard, use this tool to manually fine tune the gain parameters of the position loop, velocity loop, and current loop for optimal performance.

Parameters tool: used to set a large number of parameters, such as scaling factors for feedback input, error handling actions, etc.

Other tools include editing and debugging tools for sending Mint commands, Scope tool for observing curves, and Spy window for monitoring important parameters of axes.

4.3 Control mode

MicroFlex can be configured as one of three basic control modes through WorkBench v5:

Current (torque) control: The driver acts as a torque amplifier, and the torque command comes from analog input or host software.

Speed control: The driver acts as a speed amplifier, with speed commands coming from analog inputs or host software.

Position control: The driver receives position commands through stepper and directional inputs as a positioning system.

5. Troubleshooting

The status LED on the front panel of the drive indicates its operating status:

Evergreen: The drive is enabled (operating normally).

Flash green: firmware download in progress.

Always red: The drive has been disabled, but there are no latch errors.

Flash red: There is a power base malfunction or error. The number of flashes represents the error code (e.g. 1 flash=DC bus overvoltage trip, 3 flashes=overcurrent trip, 7 flashes=over temperature trip, etc.).

Red green flashing alternately: undervoltage warning (no AC power supply), but no latch error.

If encountering communication problems, inability to enable, or unstable operation, check the 24V power supply, serial connection, drive enable input connection, and current/speed loop tuning. Detailed error code meanings and fault diagnosis steps can be found in the help file of WorkBench v5.

6. Summary of Specification Parameters

Input power supply: 115-230VAC, single-phase or three-phase.

Continuous output current: 3A, 6A, or 9A (different models).

Peak output current: 6A, 12A or 18A respectively, lasting for 0.5 seconds.

Working environment temperature: 0 ° C to 45 ° C (higher if derating is required), with a maximum relative humidity of 93%.

Feedback interface: Incremental encoder (maximum 8MHz) or SSI (Baldor motor, resolution up to 262144 lines/rev).

Communication interface: RS232 or RS485 (9600 to 57600 baud).

Protection level: IP00 (to be installed inside the control cabinet).

By following the detailed installation, connection, configuration, and troubleshooting guidelines mentioned above, users can ensure the safe, efficient, and reliable operation of the Baldor MicroFlex servo drive system.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor