Toshiba Discrete IGBT Product Technology Analysis and Application Guide

A Comprehensive Analysis of Toshiba's Discrete IGBT Products: Technological Evolution, Product Line, and Core Applications

1. Overview of IGBT Technology and Toshiba Product Features

1.1 Basic principles and advantages of IGBT

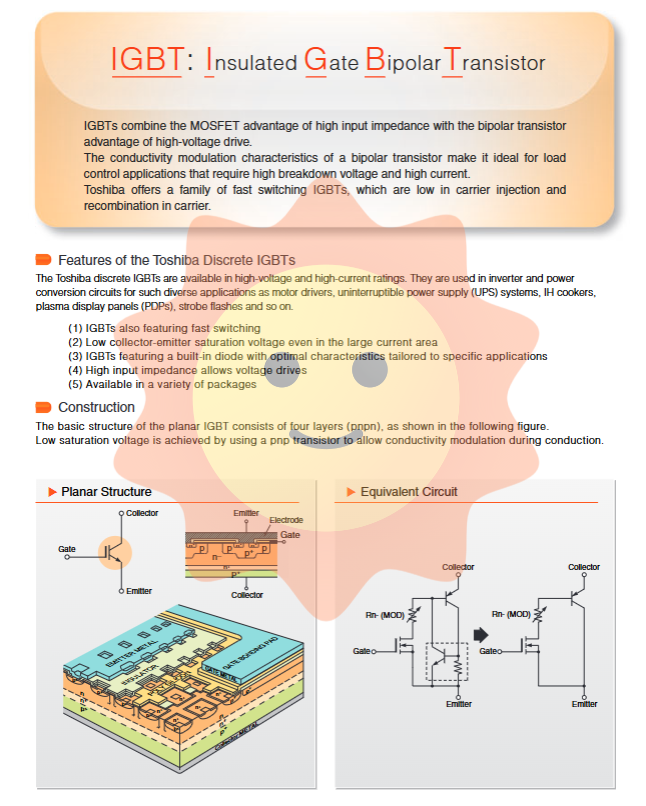

IGBT is a composite power semiconductor device with a four layer (PNPN) structure. Its basic structure (planar type) is shown in the figure, which achieves carrier modulation effect during conduction period through PNP bipolar transistor, thereby obtaining lower conduction voltage drop (VCE (sat)) under high voltage. Its equivalent circuit can be regarded as a MOSFET driving a PNP bipolar transistor.

The core advantage lies in:

High input impedance: voltage driven, simple driving circuit.

Low conduction voltage drop: Thanks to the conductivity modulation effect of bipolar structure, especially in high voltage and high current regions, it has obvious advantages.

High voltage withstand and high current capability: suitable for high-voltage power conversion applications.

1.2 Core characteristics of Toshiba discrete IGBT

Toshiba's discrete IGBT product line aims to meet diverse industrial and consumer electronics needs, with key features including:

High speed switch performance: Through optimized carrier lifetime control technology, fast switching is achieved and switch losses are reduced.

Excellent saturation voltage drop characteristics: Even under high current conditions, it can maintain a low VCE (sat), which helps reduce conduction losses.

Built in optimized diodes: Many models integrate feature optimized anti parallel fast recovery diodes (FRD) or freewheeling diodes (FWD) to simplify peripheral circuits and improve system reliability.

Rich packaging options: Provides a variety of packaging options from compact TSON-8, SOP-8 to high-power TO-220 series, TO-3P series, etc., to adapt to different power levels and installation requirements.

High robustness: Designed for harsh industrial environments, it has good impact resistance and durability.

2. Technological development trends and intergenerational evolution

Toshiba IGBT technology continues to iterate and has launched multiple generations of products for different voltage levels and application requirements. Its development trend is mainly reflected in reducing VCE (sat), improving switching speed, enhancing robustness, and adopting new structures such as trench gate and RC-IGBT.

The following table summarizes Toshiba's technological development path on IGBTs of different voltage levels:

Generation and main characteristics of voltage level development

1200 V (1) 3rd generation (high robustness): Optimized carrier injection and thinner wafers to achieve low VCEsat and high robustness.

(2) 5th generation (soft switch): adopts trench gate structure to reduce VCEsat.

(3) Generation 6.5: Adopting RC (reverse conduction) structure.

900-1500 V (1) 4th generation (soft switch): trench gate structure achieves low VCEsat.

(2) 5th generation (soft switch): optimized carrier injection combined with trench gate.

(3) 6th generation (soft switch): thinner wafers and finer processes.

(4) Generation 6.5: RC structure.

600 V (1) 3rd generation (high robustness): Optimized carrier injection and thin wafers to achieve low VCEsat and high robustness.

(2) 4th generation (high-speed switch): Optimize carrier injection to improve switch speed.

(3) 4th generation (soft switch): trench gate reduces VCEsat.

(4) 6th generation (low VCEsat): thin wafers and fine craftsmanship.

(5) 5th generation (soft switch): thin wafer.

(6) 6th generation (soft switch): thin wafers and fine craftsmanship.

400 V (1) 5th generation (flash): Trench gate structure achieves low VCEsat.

(2) 6th generation (flash): Trench gate and optimized wafer achieve high current.

(3) 7th generation (flash): Optimized wafer and fine process to achieve high current.

300-400 V (1) 4th generation (plasma display): Trench gate and lifetime control achieve low VCEsat and high IC.

(2) 5th generation (plasma display): Fine craftsmanship reduces turn-on losses.

(3) 6th generation (plasma display): Optimizing wafers and fine processes to reduce turn-on losses.

(4) 7th generation (plasma display): thinner wafers and finer processes.

Taking the VCE (sat) characteristic curve of IGBT with 900V soft switching as an example, Toshiba continuously lowers the saturation voltage drop and improves energy efficiency through continuous carrier injection optimization and process improvement.

3. Overview of Product Lines and Model Naming Rules

3.1 Product Line Matrix

Toshiba discrete IGBTs are classified by application and characteristics to form a complete product matrix, covering a wide range of voltages from 600V to 1200V and even higher, and currents from a few amperes to hundreds of amperes. There are various packaging forms, including TSON-8, SOP-8, TO-220SIS, TO-220SM (MX6), TO-3PN, TO-3P (LH), etc.

The main application series include:

Universal frequency converter/motor drive: high robustness series, high-speed switch (FS) series.

Soft switch application: a series of soft switches designed specifically for resonant transformations, such as induction cookers and microwave ovens.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor