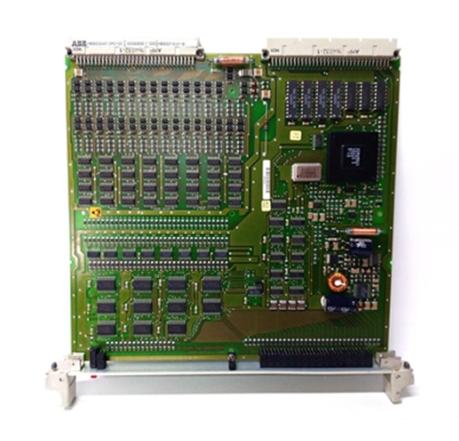

ABB 128057-204 086345-504 is a highly integrated multifunctional module for the industrial automation field. 128057-204 is the core functional module number, and 086345-504 is the matching component identification. The two work together to achieve composite functions such as signal acquisition, data processing, control output, and communication conversion. As a key peripheral component of ABB automation system, this module is designed to meet the requirements of centralized control of multiple types of signals on industrial sites. With the integration advantage of "one module for multiple purposes", it can greatly simplify the system wiring and architecture design, and is widely used in automation control systems in electric power, metallurgy, manufacturing, municipal engineering and other fields, providing an efficient signal interaction bridge between field equipment and upper controllers (such as ABB AC800M series).

ABB 128057-204 086345-504 multifunctional module

Basic overview of module

ABB 128057-204 086345-504 is a highly integrated multifunctional module for the industrial automation field. 128057-204 is the core functional module number, and 086345-504 is the matching component identification. The two work together to achieve composite functions such as signal acquisition, data processing, control output, and communication conversion. As a key peripheral component of ABB automation system, this module is designed to meet the requirements of centralized control of multiple types of signals on industrial sites. With the integration advantage of "one module for multiple purposes", it can greatly simplify the system wiring and architecture design, and is widely used in automation control systems in electric power, metallurgy, manufacturing, municipal engineering and other fields, providing an efficient signal interaction bridge between field equipment and upper controllers (such as ABB AC800M series).

Compared with traditional single function modules, this product integrates digital I/O, analog conversion, pulse counting, and basic control logic. It has independent signal processing capabilities and can seamlessly interface with the main controller through standard industrial buses. It can serve as a distributed I/O unit to expand system perception capabilities and undertake local control tasks in small control scenarios, providing a flexible and economical solution for automation systems.

Core performance characteristics

1. Multi type signal processing with high integration

The module has the ability to process all types of signals and can simultaneously access digital input/output, analog input/output, and pulse signals without the need for additional dedicated modules. The analog channel supports the acquisition of 4-20mA current signals and 0-10V voltage signals, and is compatible with temperature sensors such as thermocouples and thermal resistors. It can directly achieve accurate acquisition of physical quantities such as temperature, pressure, and flow in industrial sites; The digital channel supports dry contact and PNP/NPN wet contact signals, meeting the monitoring and control of discrete signals such as motor start stop status and valve switch position; The pulse channel can count the pulse signals output by encoders, flow meters, and other devices at high speed, achieving the accumulation and real-time calculation of parameters such as speed and flow rate. Multi functional integrated design not only reduces the number of modules and installation space, but also lowers the system failure rate and maintenance costs.

2. High precision signal conversion, strong data reliability

The module adopts a 16 bit high-precision A/D conversion chip, with an analog acquisition accuracy of ± 0.1% FS and a temperature drift of ≤ 5ppm/℃, ensuring data stability even in industrial temperature fluctuation environments. For complex electromagnetic environments, the module is equipped with a built-in signal isolation circuit, which achieves 2500Vrms electrical isolation between analog and digital channels, as well as between channels and power supplies, effectively suppressing common mode interference and differential mode interference; Simultaneously equipped with signal filtering algorithms, it can effectively filter high-frequency noise and instantaneous pulses, ensuring the authenticity and accuracy of collected data, and providing reliable basis for control decisions.

3. Flexible control mode with wide adaptability

The module supports dual-mode operation of "slave control" and "independent control": in slave mode, it receives instructions from the upper controller through standard communication protocols such as PROFINET and Modbus RTU, performs signal acquisition and output control, and becomes a distributed expansion unit of the system; In independent mode, a simple logic configuration tool built into the module can be used to preset linkage control logic based on input signals (such as threshold triggering, delay output, pulse counting standard alarm, etc.), which can achieve automatic control of local equipment without relying on the main controller. It is suitable for simple control scenarios such as water pump start stop, fan speed regulation, liquid level interlocking, etc., improving system response speed and fault tolerance.

4. Industrial grade protection design with excellent environmental adaptability

The module adopts an industrial grade reinforced shell, which has undergone anti-corrosion treatment on the surface and can resist the erosion of oil and dust on site. The hardware design meets the requirements of wide temperature operation, and can operate stably in a temperature range of -20 ℃~70 ℃ and a humidity environment of 5%~95% (without condensation). At the same time, it has anti vibration (10-500Hz, 1g acceleration) and anti impact (10g, 11ms) performance, which complies with the IEC 60068 industrial environmental adaptability standard. The module wiring terminal adopts a spring crimping design, which ensures reliable contact and resistance to vibration loosening. It is compatible with 1.0-2.5mm ² wires and meets the mechanical and environmental requirements for long-term stable operation in industrial sites.

5. Convenient configuration and diagnosis, low operation and maintenance costs

The module supports parameter configuration through ABB dedicated configuration software or third-party general tools, which can intuitively set channel types, signal ranges, alarm thresholds, communication addresses, and other parameters. After configuration is completed, the parameters can be permanently saved without loss during power outages. Built in comprehensive self diagnostic function, which can monitor module power status, channel faults, communication link quality, etc. in real time. Fault information is output through LED indicator lights (power, operation, fault) and communication messages, making it easy for operation and maintenance personnel to quickly locate problems. In addition, the module supports online hot plugging (with compatible base), which can be replaced without stopping the machine, greatly reducing maintenance time.

Key technical parameters

Basic Information

Module Number

128057-204 (core module); 086345-504 (Supporting Components)

Basic Information

Installation method

DIN rail installation (35mm standard rail)

Digital channel

Input channel

16 channels, supporting dry/wet contacts, response time ≤ 1ms

Digital channel

Output channel

8 channels, relay output (2A/250VAC) or transistor output (0.5A/24VDC) optional

Analog Channel

Input channel

8 channels, supporting 4-20mA/0-10V, compatible with PT100 and K-type thermocouples

Analog Channel

Output channel

4-channel, 4-20mA current output, load capacity ≤ 500 Ω

Pulse channel

counting function

2-channel high-speed pulse input, maximum counting frequency 10kHz, supports forward/reverse counting

Communication performance

communication interface

1 RS485, 1 Ethernet interface (RJ45)

Communication performance

Supported Protocols

Modbus RTU/TCP, PROFINET, ABB AC800M dedicated communication protocol

precision metric

Analog accuracy

± 0.1% FS, linearity ≤ 0.05% FS

precision metric

Counting accuracy

± 1 pulse

Power requirements

input voltage

24V DC (± 15%), supports reverse polarity protection

Power requirements

Typical power consumption

≤ 12W (full load state)

environmental conditions

Protection level

IP20 (module body), compatible with IP54 and above control cabinets

environmental conditions

Operating Temperature

-20 ℃~70 ℃, storage temperature -40 ℃~85 ℃

Typical application scenarios

1. Manufacturing production line: In production lines for automotive parts, electronic components, etc., it is used to centrally collect equipment operating status (such as motor start/stop, sensor signals), process parameters (such as welding temperature, assembly pressure), and output control signals to drive solenoid valves, indicator lights, and other actuating components. With the main controller, it can achieve automated linkage of the production line. The multi-channel integration feature of the module can simplify the wiring of the production line and reduce the equipment footprint.

2. Power equipment monitoring: In the automation system of substations and distribution rooms, as a dedicated monitoring module, it collects electrical parameters such as current, voltage, power factor, as well as discrete quantities such as switch status and fault signals from distribution cabinets. The data is uploaded to the SCADA system through Ethernet, and functions such as overload alarm and trip signal output are implemented according to preset logic to enhance the intelligence level of power system operation and maintenance.

3. Rolling mill control in the metallurgical industry: In the steel rolling production line of the steel plant, tension sensors and speed encoder signals of the rolling mill are connected, and preliminary adjustment of tension and speed is achieved through the built-in logic of the module. At the same time, real-time data is uploaded to the AC800M main controller to assist in precise control of the rolling process. Its anti vibration and wide temperature characteristics can adapt to the harsh environment of the metallurgical site.

4. Municipal water supply system: In water plants and sewage treatment plants, centralized monitoring of pump outlet pressure, pool liquid level, water quality indicators (such as turbidity, pH value) and other signals is carried out. Control signals are output through modules to adjust pump speed and valve opening. In independent mode, interlocking control of "automatic pump start when low liquid level and automatic pump stop when high liquid level" can be achieved to ensure the continuity of the water supply/sewage treatment process.

5. Intelligent warehousing system: In an automated three-dimensional warehouse, it is used to collect position encoder signals and cargo position detection sensor signals from stacker cranes, output control signals to drive the stacker crane's walking and lifting mechanisms, and communicate with the warehouse management system through Modbus protocol to achieve automated control of cargo access. The multifunctional integration feature reduces the control complexity of warehouse equipment.

Installation and usage precautions

-Module installation should choose a location with good ventilation and no direct sunlight exposure. When installing DIN rails, it is necessary to ensure that the buckles are firm, and the module spacing should be reserved at least 5mm to ensure heat dissipation; If there is a strong electromagnetic interference source (such as a frequency converter) on site, the distance between the module and the interference source should be ≥ 1 meter, or a metal shielding cover should be used for protection.

-Before wiring, the module power supply should be disconnected, and the power supply and signal input/output terminals should be strictly distinguished according to the wiring terminal diagram. Analog signal cables should use shielded twisted pair cables, and the shielding layer should be grounded at one end; When driving high-power devices with digital output channels, it is necessary to parallel a freewheeling diode at the device end to prevent relay contact burnout.

-Before the first use, the channel parameters need to be initialized through configuration software, including analog signal type (current/voltage/thermocouple), digital input polarity, communication address, baud rate, etc. After configuration, signal calibration is required, especially for analog channels, which need to use standard signal sources for accuracy verification.

-When communicating between the module and the upper controller, it is necessary to ensure that the communication protocol, address, and baud rate (RS485 only) of both are consistent. Ethernet communication requires configuring the same IP address in the same network segment; During communication link testing, it is important to focus on checking the real-time and integrity of data transmission to avoid control errors caused by communication delays.

-In daily operation and maintenance, regularly clean the dust on the surface of the module, check whether the wiring terminals are loose, and whether the LED indicator light status is normal; If there is a channel failure, the replacement method can be used to investigate whether it is a problem with the module itself or an external signal problem. When replacing the module, it is necessary to ensure that the parameters of the new module are completely consistent with the original module to avoid system configuration confusion.

-Module firmware upgrade requires the use of ABB's official upgrade tool and firmware version. During the upgrade process, the power must not be cut off. After the upgrade is completed, the module needs to be restarted and the parameters need to be rechecked to ensure normal functionality after the upgrade.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-