The Weidmuller 836598 is a basic, feed-through (universal) terminal block designed for DIN rail mounting. It serves as a fundamental connection and distribution point for electrical wires in control cabinets, featuring a screw clamp connection, a transparent housing for inspection, and compatibility with marking tags for circuit identification.

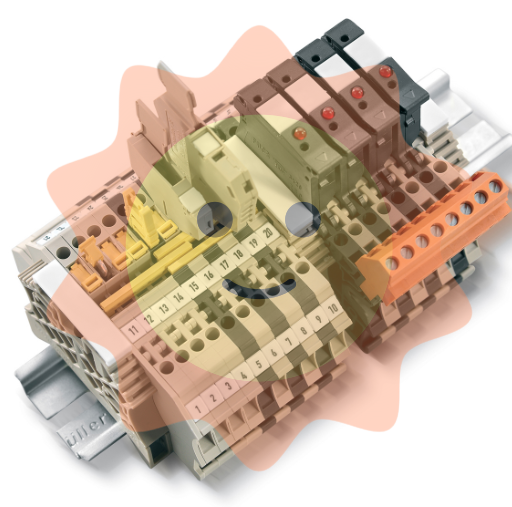

WEIDMULLER 836598 Terminal Block

Product Introduction: The Weidmuller 836598 is a basic, feed-through (universal) terminal block designed for DIN rail mounting. It serves as a fundamental connection and distribution point for electrical wires in control cabinets, featuring a screw clamp connection, a transparent housing for inspection, and compatibility with marking tags for circuit identification.

Product Overview and Functional Purpose

The Weidmuller 836598 is a fundamental component in the field of electrical interconnection technology. It belongs to the category of universal or feed-through terminal blocks, meaning its primary function is to provide a simple, secure, and organized point to connect two or more wires. It acts as an interface within an electrical circuit, allowing for the termination, junction, or distribution of conductors. This terminal block is mounted on a standard DIN rail (TS35) inside control panels, enclosures, or distribution boxes. Its design is centered on reliability and ease of use, making it a ubiquitous choice for establishing basic electrical connections in both power and control circuits. By providing a clear and accessible connection point, it enhances safety, simplifies wiring, and facilitates maintenance and troubleshooting.

Core Design Features and Construction

The 836598 incorporates several key design elements that contribute to its widespread use. The connection is made via a robust screw clamp mechanism. A captive pressure plate ensures a gas-tight, vibration-resistant connection that is suitable for a wide range of conductor types, from fine-stranded wires (with ferrules) to solid cores. The transparent polyamide (PA) housing allows for visual inspection of the wire seating and the screw position, a critical feature for quality control. The terminal features an integrated marking area that accepts standard marking tags (often 5mm wide), enabling clear and permanent identification of the wire function or circuit number. Its compact design with a standard pitch (likely 5mm or 5.08mm) allows for high-density mounting on DIN rails, maximizing space utilization within enclosures.

Technical Specifications

The performance and application limits of the Weidmuller 836598 are defined by its technical specifications:

Manufacturer Part Number: Weidmuller 836598

Product Type: Feed-Through / Universal Terminal Block

Rated Voltage: Typically 400V / 500V, suitable for common industrial and commercial voltage levels.

Rated Current: Standard current rating (e.g., 17A, 20A) for reliable power and signal carrying.

Wire Range: Accepts a broad range of conductor cross-sections (e.g., 0.14 mm² to 4 mm² or AWG 26-12).

Connection Technology: Screw clamp with captive pressure plate (cage clamp style).

Number of Connection Points: Typically one entry and one exit point per level (single-tier, feed-through).

Pitch: Standard 5.0mm or 5.08mm spacing between adjacent terminals.

Housing Material: Transparent Polyamide (PA 6.6), flame-retardant to UL94 V-0.

Contact Material: Tin-plated electrolytic copper alloy for excellent conductivity.

Mounting: Snap-fit mounting on standard top-hat DIN rail TS35 (35mm x 7.5mm).

Operating Temperature: Standard industrial range, typically -40°C to +100°C.

Marking: Compatible with slip-on or clip-on marking tags.

Standards: Complies with international standards such as IEC, UL, CSA, and VDE.

Common Industrial Applications

The Weidmuller 836598 is a versatile workhorse found in virtually every sector that uses electrical control and distribution.

Industrial Control Panels (PLC Cabinets)

Used as the primary terminal point for connecting field device wiring (sensors, switches, motors) to the terminals of PLC I/O modules, circuit breakers, and contactors, organizing the panel's internal wiring.

Power Distribution and Switchgear

Employed in distribution boards and motor control centers (MCCs) to create common neutral/ground bars, distribute power to multiple branches, and provide test points.

Machinery and OEM Equipment

Integrated into the control cabinets of machine tools, packaging machines, and conveyor systems to manage internal power and control wiring between components.

Building Automation and HVAC

Used in control panels for building management systems, lighting control, and HVAC units to terminate control and power cables from various field devices.

Installation and Wiring Guidelines

Proper installation is straightforward but critical for performance. First, snap the terminal block onto a DIN rail by hooking the lower lip and pressing until it clicks into place. For wiring, strip the conductor to the recommended length. If using stranded wire, applying a ferrule is highly recommended to prevent splaying and ensure optimal contact. Insert the prepared wire into the clamping unit beneath the pressure plate. Tighten the screw with a suitable screwdriver to the manufacturer's specified torque. Avoid over-tightening, which can damage the conductor or the terminal. Finally, insert a marked identification tag into the slot on the transparent housing. For maintenance, the terminal block can be easily removed from the DIN rail using a screwdriver to lift the spring-loaded mounting foot.

Conclusion

The Weidmuller 836598 feed-through terminal block is a foundational element of safe and organized electrical installations. Its simple yet effective design—combining a reliable screw clamp, a transparent inspection window, and DIN rail compatibility—makes it an indispensable component for panel builders, electricians, and engineers. By facilitating clear, secure, and identifiable wire connections, it directly contributes to the reliability, serviceability, and safety of industrial control systems and power distribution networks. Its adherence to international standards and broad application range cement its position as a go-to solution for basic interconnection needs across countless industries. Choosing the 836598 is a choice for proven quality, simplicity, and long-term connection integrity.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-