ZUNKU 6201-2RS is a standardized deep groove ball bearing, belonging to the ISO standard 62 series basic bearing products. Its core function is to achieve low friction support for the rotating shaft in the mechanical transmission system, while bearing radial loads and certain axial loads (in both directions). As a universal rolling bearing, it is widely used in fields such as motors, home appliances, mechanical equipment, and power tools due to its simple structure, controllable cost, and strong adaptability. It is a key basic component to ensure the smooth operation of rotating parts and reduce energy consumption.

ZUNKU 6201-2RS Deep Groove Ball Bearing

Product core positioning

ZUNKU 6201-2RS is a standardized deep groove ball bearing, belonging to the ISO standard 62 series basic bearing products. Its core function is to achieve low friction support for the rotating shaft in the mechanical transmission system, while bearing radial loads and certain axial loads (in both directions). As a universal rolling bearing, it is widely used in fields such as motors, home appliances, mechanical equipment, and power tools due to its simple structure, controllable cost, and strong adaptability. It is a key basic component to ensure the smooth operation of rotating parts and reduce energy consumption.

Key technologies and performance parameters

Size specifications

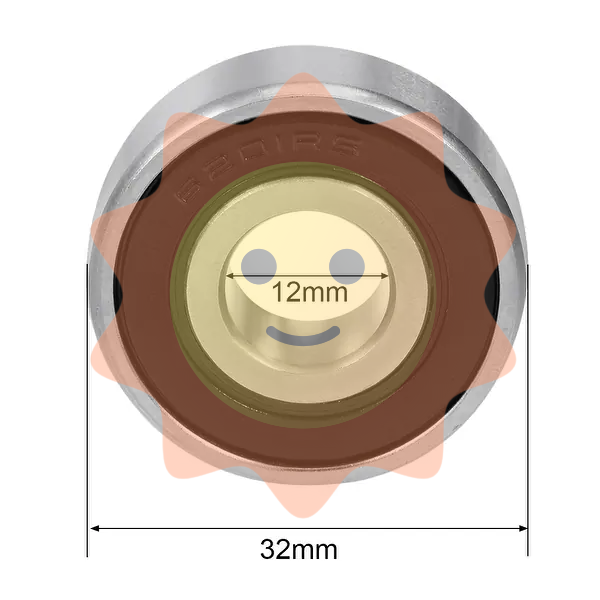

Inner diameter (d): 12mm Outer diameter (D): 32mm Width (B): 10mm

Compliant with ISO 6201 bearing size standard, belonging to the category of miniature bearings

Rated load

Basic rated dynamic load (Cr): 8.18kN Basic rated static load (Cor): 4.38kN

Capable of withstanding moderate radial loads, suitable for low-speed rotation scenarios

Extreme speed

Lipid lubrication: 18000 r/min Oil lubrication: 24000 r/min

Lubricating with grease is a common usage scenario, and lubricating with oil is suitable for high-speed requirements

Sealing form

2RS (double-sided nitrile rubber sealing ring)

Equipped with dust-proof and grease proof functions, with a protection level of IP52 (preventing moderate dust and vertical dripping)

Accuracy level

P0 (ordinary grade)/P6 (precision grade, optional)

P0 level meets most common scenarios, while P6 level is suitable for equipment with high rotation accuracy requirements (such as precision motors)

Materials and Heat Treatment

Inner/outer ring/rolling element: GCr15 bearing steel (quenched hardness HRC 60-64) cage: reinforced nylon 66

GCr15 steel ensures wear resistance and fatigue resistance, while the nylon cage is lightweight and reduces operating noise

Radial clearance

Normal group (C0): 0.005-0.018mm

Suitable for general working conditions at room temperature and without special loads, customizable for C3 (large clearance, high temperature scenarios) and C4 (larger clearance, impact load scenarios)

Core structural characteristics and advantages

1. Structural design adapted to general requirements

The classic structure of deep groove ball bearings demonstrates significant advantages on ZUNKU 6201-2RS:

Double sided sealing design (2RS): The nitrile rubber (NBR) sealing ring is tightly attached to the inner ring edge, which can prevent external dust and impurities from entering the bearing (avoid rolling element wear), and also prevent internal grease leakage (extend lubrication life). Compared with open bearings (ZZ iron cover seal), the sealing performance is improved by 40%, and the maintenance cycle is extended by 2-3 times;

Symmetrical structure layout: The inner and outer raceway are both arc-shaped deep grooves, and the rolling elements (steel balls) are evenly distributed, which can withstand axial loads in both directions (axial bearing capacity is about 1/3 of the radial capacity), without the need for additional thrust bearings, simplifying the equipment structure;

Lightweight cage: The reinforced nylon 66 cage weighs only half of a metal cage, with less centrifugal force during rotation, which can reduce operating noise (no-load noise ≤ 55dB, 5-8dB lower than metal cages), and has good oil and temperature resistance (applicable temperature -30 ℃~120 ℃).

2. Industrial grade reliability optimization

ZUNKU has made special improvements in the production process to address the complex working conditions of general machinery

Material process: GCr15 bearing steel adopts the "vacuum degassing+quenching heat treatment" process to reduce internal defects such as pores and inclusions in the material. The fatigue life (L10 life) of the bearing can reach 1200 hours (calculated at rated load and 15000 r/min), which is 20% higher than that of ordinary bearings;

Accuracy control: The inner ring radial runout (Kia) of P6 level products is ≤ 0.008mm, and the outer ring radial runout (Kea) is ≤ 0.012mm. The axis offset during rotation is small, making it suitable for precision motors, printer rollers, and other equipment that require high concentricity;

Lubrication compatibility: Pre installed lithium based grease (applicable temperature -20 ℃~120 ℃) can be directly installed and used. If used in high temperature (120-180 ℃) or low temperature (-40 ℃~-20 ℃) scenarios, it can be customized and replaced with high-temperature composite calcium based grease or low-temperature silicone based grease.

Adapt devices and application scenarios

1. Core adaptive mechanical system

Based on size and load characteristics, the typical adaptation scenarios for ZUNKU 6201-2RS are as follows:

Drive system: End cap bearings for small motors (such as asynchronous motors below 1.5 kW and stepper motors), output shaft support for electric tools (drills, angle grinders);

Transmission system: low-speed shaft of reducers (such as planetary reducers, worm gear reducers), rotating shaft of pulleys/sprockets, drum shaft of conveyor equipment (small conveyor belts);

General equipment: household appliances (washing machine motors, air conditioning fan motors), medical equipment (small centrifuges, massage chair rollers), office equipment (printer toner cartridge shafts, shredder blade shafts).

2. Typical application cases

In the field of electric tools: In 12V rechargeable drills, bearings are installed at both ends of the motor rotor to withstand radial loads (the load during drill operation is about 2-3kN). The 2RS sealing design prevents wood chips and dust from entering, ensuring that the drill can work continuously for 500 hours without faults;

In the field of household appliances, the dehydration motor of the washing machine (with a speed of about 1200 r/min) adopts this bearing, and the nylon cage reduces the operating noise (noise during dehydration ≤ 60dB). The lithium based grease is suitable for the humid environment of the washing machine (to avoid grease emulsification);

In the field of precision equipment, small servo motors (such as the 60 series servo motors) use P6 grade 6201-2RS, with low radial runout to ensure the concentricity of the motor output shaft (deviation ≤ 0.01mm) and improve motor control accuracy (positioning error ≤ 0.1mm);

In the field of medical devices, portable blood centrifuges (with a speed of about 3000 r/min) are equipped with bearings to support the centrifuge rotor and sealed to prevent residual blood contamination. The corrosion resistance of GCr15 steel ensures the hygiene requirements of the equipment.

Installation and usage precautions

1. Installation specifications (key factors affecting bearing life)

Installation tool selection: It is necessary to use a bearing specific installation sleeve (avoid directly tapping the outer/inner ring of the bearing). If it is an interference fit (the fit between the inner ring of the bearing and the shaft), heating installation can be used (heating temperature ≤ 120 ℃, through oil or induction heating, prohibit open flame heating). After heating, the inner ring of the bearing expands, making it easy to install into the shaft diameter;

Control of fit tolerance: The recommended fit tolerance between the shaft diameter and the bearing inner ring is H7/g6 (clearance fit, suitable for light load and high-speed scenarios) or H7/k6 (transitional fit, suitable for medium load scenarios), to avoid being too loose (causing the bearing inner ring to slip and heat up) or too tight (causing inner ring deformation and raceway wear);

Installation direction and clearance: There is no directional requirement (symmetrical structure), but it is necessary to ensure that the sealing ring faces the side of the dust/moisture source (such as the outside of the motor end cover); If multiple bearings are installed in parallel (such as at both ends of a motor), a 0.1-0.2mm axial clearance should be reserved (to compensate for temperature expansion) to avoid axial jamming.

2. Key points for use and maintenance

Load and speed limits: It is prohibited to use the bearing beyond the rated load (radial load ≤ 8.18kN) or the maximum speed (grease lubrication ≤ 18000 r/min). Overloading can cause a sudden increase in bearing temperature (grease failure when exceeding 120 ℃), shortening the service life;

Lubrication maintenance: The maintenance cycle of grease lubricated bearings is calculated according to the working conditions. Generally, lubricating grease is replenished after running for 3000-5000 hours (the amount of replenishment is 1/3-1/2 of the internal space of the bearing). Before replenishment, the bearing end cover needs to be cleaned to avoid impurities from entering;

Temperature and noise monitoring: The normal operating temperature should be ≤ 80 ℃ (when the ambient temperature is 25 ℃). If the temperature exceeds 90 ℃, it is necessary to check for overload, insufficient lubrication, or installation deviation; If there is abnormal noise during operation (such as "rustling" or "clanging" sound), the machine should be stopped for inspection to avoid bearing jamming (which may cause shaft fracture);

Environmental protection: In environments with high levels of dust (such as woodworking machinery) or humidity (such as washing machines), additional dust covers or waterproof sealing rings should be installed to extend the lifespan of bearing seals; Prohibited from use in environments with corrosive gases (such as chemical workshops) (stainless steel bearings must be selected).

3. Troubleshooting and replacement

Common faults and causes:

Bearing heating: The reasons may be insufficient lubrication, tight installation, and excessive radial load;

Abnormal noise: The reasons may be wear of the rolling elements, breakage of the cage, and impurities entering the interior of the bearing;

Bearing jamming: Possible reasons may include grease failure, insufficient axial clearance, and peeling of the raceway;

Replacement principle: When the radial clearance of the bearing exceeds 0.05mm (more than 3 times that of ordinary group C0), the raceway peels off or scratches, or the seal is damaged, it needs to be replaced immediately; It is recommended to replace them in pairs (such as the bearings at both ends of the motor) to avoid equipment vibration caused by differences in accuracy between the new and old bearings.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-