The YOKOGAWA AIP591 process control module is a core analog control component designed by Yokogawa Electric for industrial automation distributed control systems (DCS) in Japan. It is mainly used for the acquisition, processing, and precise control of process parameters in industrial sites, and is compatible with mainstream DCS architectures such as Yokogawa CENTUM CS/VP. It can be seamlessly integrated into ESB bus node units (such as ANB10S/10D, ANB11S/11D) and field control units (such as AFV30S/30D, AFV40S/40D, etc.). As a key bridge between on-site equipment and control systems, this module has the ability to adapt to multiple types of analog signals, and can real-time collect and closed-loop control core process parameters such as temperature, pressure, flow rate, and liquid level. At the same time, it integrates a complete alarm mechanism and fault diagnosis function, which can effectively ensure the stability and safety of industrial production processes. Its modular design balances installation convenience and maintenance flexibility, supports redundant configuration, and can greatly improve system availability. It is widely used in continuous process industrial scenarios such as petrochemicals, power, metallurgy, etc., which require extremely high control accuracy and reliability.

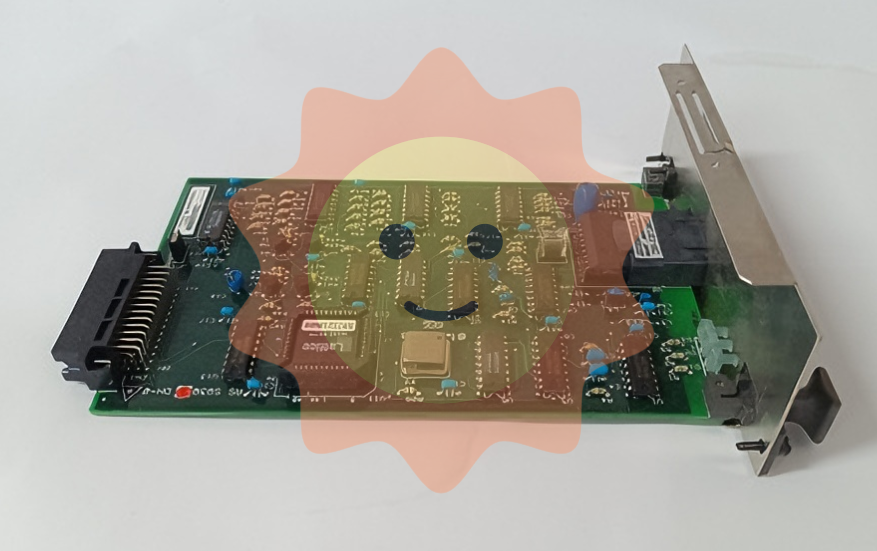

YOKOGAWA AIP591 Process Control Module

Product Overview

The YOKOGAWA AIP591 process control module is a core analog control component designed by Yokogawa Electric for industrial automation distributed control systems (DCS) in Japan. It is mainly used for the acquisition, processing, and precise control of process parameters in industrial sites, and is compatible with mainstream DCS architectures such as Yokogawa CENTUM CS/VP. It can be seamlessly integrated into ESB bus node units (such as ANB10S/10D, ANB11S/11D) and field control units (such as AFV30S/30D, AFV40S/40D, etc.). As a key bridge between on-site equipment and control systems, this module has the ability to adapt to multiple types of analog signals, and can real-time collect and closed-loop control core process parameters such as temperature, pressure, flow rate, and liquid level. At the same time, it integrates a complete alarm mechanism and fault diagnosis function, which can effectively ensure the stability and safety of industrial production processes. Its modular design balances installation convenience and maintenance flexibility, supports redundant configuration, and can greatly improve system availability. It is widely used in continuous process industrial scenarios such as petrochemicals, power, metallurgy, etc., which require extremely high control accuracy and reliability.

Specification parameters

The YOKOGAWA AIP591 process control module matches the stringent requirements of industrial process control with precise technical parameters. The core specification parameters have been validated in industrial grade environments, and the specific details are as follows:

-Basic information: The model is AIP591, the manufacturer is YOKOGAWA (Yokogawa Electric), the product type is industrial grade process control module, and the country of origin is Japan; The core adaptation system is the Yokogawa CENTUM CS/VP distributed control system, which supports ESB bus, ER bus node units, and various on-site control units;

-Input/output specifications: Supports multiple types of analog input/output signals, including 4-20mA and 0-20mA linear current signals, 0-60mV, 0-1V, 0-5V, 1-5V, and -10~10V linear voltage signals, and can be adapted to 2-wire/4-wire transmitters; The output signal is mainly composed of 4-20mA standard current signal, which is used to drive the on-site actuator;

-Accuracy and response performance: Input accuracy reaches ± 0.1% FS, current input error is ≤± 16 μ A, voltage input error is ≤± 4mV (1-5V range), ± 20mV (-10~10V range); Data update cycle ≤ 10ms, step response time ≤ 100ms, ensuring fast response of control instructions;

-Channel configuration: Adopting a 16 channel non isolated design (some channels support differential input), each channel input type can be independently configured to meet the requirements of multi parameter parallel monitoring and control;

-Power parameters: The power supply voltage is a dual power supply of DC 5V and DC 24V, with a typical power consumption of ≤ 350mA for 5V power supply and ≤ 120mA for 24V power supply. It has power reverse connection protection and overcurrent protection functions to prevent equipment damage caused by abnormal power supply;

-Environmental adaptability parameters: operating temperature range of 0 ° C~50 ° C, storage temperature range of -20 ° C~70 ° C; relative humidity adaptability range of 0~95% RH (non condensing); Can withstand vibration intensity of 10~55Hz, 0.3mm amplitude (sine wave, X/Y/Z direction, 30 minutes each), and impact intensity of 10G (11ms, half sine wave, X/Y/Z direction, 3 times each);

-Physical and installation parameters: Adopting a compact modular design, the external dimensions (length x width x height) are approximately 100mm x 127mm x 25mm (excluding installation accessories), with a weight of approximately 0.2kg; the installation method is standard rail installation or module slot installation, suitable for dense layout inside the control cabinet;

-Safety and electromagnetic compatibility parameters: comply with international safety standards such as IEC 61010-1 and UL 61010-1; Electromagnetic radiation (EMI) meets the EN 55022 Class A standard, and electromagnetic immunity (EMS) meets the EN 55024 standard. It has good electromagnetic shielding performance and can resist electromagnetic interference generated by industrial field frequency converters, motors, and other equipment.

Performance characteristics

The YOKOGAWA AIP591 process control module integrates Yokogawa Electric's core technology in the industrial control field, and has multiple core performance advantages to meet the needs of process control scenarios, comprehensively ensuring the accuracy and reliability of the control process

-Multi type signal adaptation, flexible adaptation to on-site requirements: supports multiple standard analog input and output signals, and can flexibly configure channel parameters according to the type of sensors and transmitters on site, without the need for additional signal conversion equipment, greatly improving the universality and adaptability of the module;

-High precision acquisition and fast response ensure control accuracy: using high-precision A/D and D/A conversion circuits and optimized signal processing algorithms, the input accuracy reaches ± 0.1% FS, which can accurately collect small signal changes; The data update cycle and step response time are short, ensuring fast issuance of control instructions and achieving precise closed-loop control of process parameters;

-A comprehensive alarm mechanism for timely warning of fault risks: supports multiple process alarm modes such as high limit alarm, low limit alarm, and high low limit combination alarm, and can set alarm lag values to avoid false alarms caused by noise interference; Provide two modes of alarm: normal alarm and lock alarm. After the lock alarm is triggered, it needs to be manually reset to ensure that fault information is not missed; When the sensor is disconnected or the A/D conversion fails, the fault transfer function can be triggered to ensure system safety;

-Support redundant configuration and improve system availability: Dual redundant configuration mode can be adopted. When the main module fails, the backup module can seamlessly take over the control task, ensuring that the control process is not interrupted, greatly improving the reliability and availability of the entire control system, and adapting to the control requirements of key process links;

-Industrial grade stable operation, suitable for harsh on-site environments: using industrial grade electronic components and rigorous production processes, it has a wide temperature working range and good anti vibration and anti impact performance; Excellent electromagnetic compatibility performance can effectively resist electromagnetic interference in industrial sites, ensuring continuous and stable operation in harsh environments with high dust and humidity fluctuations, with an average time between failures (MTBF) of over 100000 hours;

-Modular design simplifies installation and maintenance: adopting standardized modular structure and interfaces, it can quickly insert node units or control units of Yokogawa DCS system, making installation and replacement convenient; The front of the module is equipped with clear status indicator lights, which can intuitively provide feedback on the power status, channel working status, and alarm information, making it easy for operation and maintenance personnel to quickly locate the fault point and reduce maintenance costs.

Working principle

The core working principle of YOKOGAWA AIP591 process control module is to achieve the collection, processing, control and feedback of process parameters in industrial sites. Its workflow mainly includes four key links: signal acquisition and conversion, data processing and control operation, control output and feedback, fault monitoring and alarm. Each link works together to ensure the accuracy and stability of the control process:

The first step is signal acquisition and conversion. The analog signals output by on-site sensors or transmitters (such as 4-20mA current signals, 1-5V voltage signals) enter the internal circuit through the input terminals of the module, and first pass through the signal filtering circuit to filter out electromagnetic interference noise in the industrial environment; Subsequently, the filtered analog signal enters a high-precision A/D conversion circuit to convert the analog signal into a digital signal, while completing signal range conversion and calibration to ensure that the digital signal can accurately represent the on-site process parameters.

Step 2: Data processing and control operations. The converted digital signal is transmitted to the core control unit of the module, which performs real-time calculations based on preset control logic (such as PID control algorithm) and parameters (set value, proportional coefficient, integration time, differentiation time, etc.); At the same time, the control unit evaluates the validity of the collected data, compares it with the preset alarm threshold, and determines whether to trigger high limit, low limit, and other alarms.

Step three: Control output and feedback. The control unit generates corresponding control instructions based on the calculation results, converts the digital control instructions into standard analog output signals (such as 4-20mA) through a D/A conversion circuit, drives on-site actuators (such as regulating valves and frequency converters) to operate, and achieves closed-loop control of process parameters; At the same time, the module will provide real-time feedback on the collected process parameters, control instruction execution status, and other data to the upper control system, ensuring that operators can grasp the on-site control situation in real time.

Section 4: Fault Monitoring and Alarm. Throughout the entire working process, the built-in fault monitoring circuit of the module monitors key parameters such as power status, A/D/D/A conversion status, and sensor connection status in real-time; When detecting sensor disconnection, conversion failure, power supply abnormality, etc., immediately trigger the fault alarm mechanism, light up the alarm signal through the status indicator light, and feedback the fault information to the upper system; If the fault transfer function is enabled, the alarm output status will be controlled according to the preset logic to prevent the fault from expanding and affecting production safety.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-