Meggitt Vibro meter VM600Mk2 Mechanical Protection and Condition Monitoring System

VM600Mk2 Second Generation Mechanical Protection and Condition Monitoring Platform

The VM600Mk2 launched by Meggitt Vibro meter is a significant evolution based on the first generation VM600 platform, which has been installed in over 8000 sets worldwide. The new generation platform inherits the design philosophy of "single module all-around" while facing new era challenges such as network security, system integration, and component availability. Through architectural innovation, it achieves a high degree of integration of protection and monitoring without the need for "dismantling and upgrading" existing systems.

The first generation VM600: Establishing the industry benchmark of "simplicity without reduction"

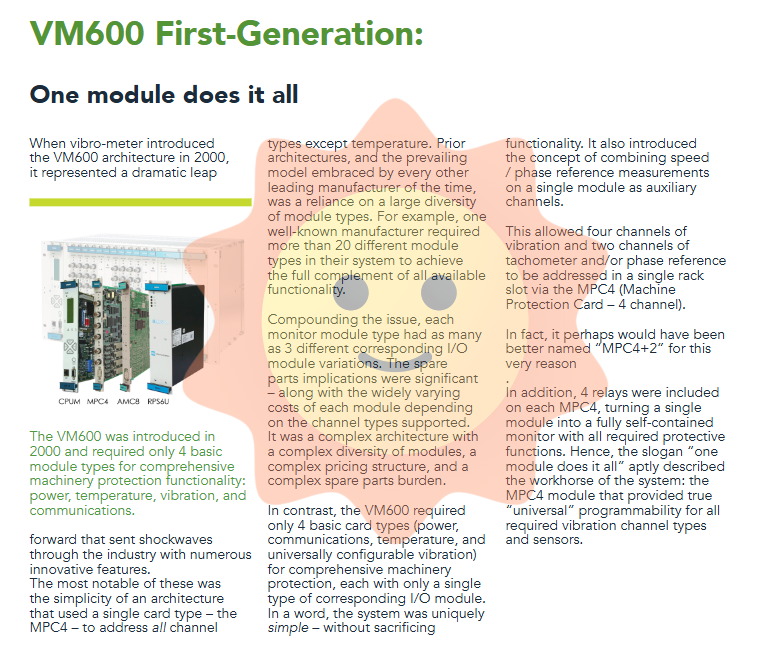

The first generation VM600, which was launched in 2000, shook the industry with its revolutionary architecture:

The module is highly versatile: a complete mechanical protection system can be built with only four basic cards: power supply, temperature, vibration (MPC4), and communication, while the mainstream solution at that time required more than 20 modules.

Physical isolation monitoring: Innovatively using independent XMV16 (vibration) and XMC16 (combustion dynamics) modules for status monitoring, completely isolated from the MPC4 protection module in hardware, ensuring that the protection function is never compromised due to monitoring system failures.

Fully compliant with API 670: Strictly following the mechanical protection system standards of the American Petroleum Institute, becoming the cornerstone of trust for customers in the oil, gas, and many power industries.

Why do we need a second generation? Addressing the core challenges in evolution

Cybersecurity: When designing the first generation products, industrial cyber attacks had not yet become a threat. Nowadays, the risk of cyber attacks on critical infrastructure, especially the power grid, is rapidly increasing, requiring systems to have endogenous security design.

System Integration: Although the complete isolation of protection and monitoring improves security, it also leads to problems such as cumbersome configuration, asynchronous data, and small differences in alarm timing, which affect user experience and event analysis.

Component availability: After more than 20 years, some electronic components are facing production shutdowns and need to ensure a long-term stable supply chain and certification maintenance through a new platform.

Refuse to 'dismantle and replace': To protect customers' existing investments, the new platform must achieve backward compatibility, allowing new and old modules to be mixed in the same rack, reusing existing backboards, power supplies, and wiring.

Core Innovation and Improvement of VM600Mk2

1. Integrated Condition Monitoring

Revolutionary MPC4MK2 module: Integrating the previously independent XMV16 status monitoring function into the protection module MPC4MK2. A single module provides protection level measurement and advanced monitoring analysis at the same time, eliminating the difference of dual path data.

Data synchronization and enhancement: The measurement values and alarm status of the protection system can be seamlessly shared to the VibroSight monitoring software. Users can add additional software calculation parameters and warning alarms on top of data protection to achieve earlier fault warnings.

2. Built in network security and functional security

Design in accordance with IEC 62443: The new architecture strengthens network security from both hardware and communication perspectives. The CPUMMk2 module is equipped with a key switch and password protection to ensure that configuration changes require both physical and logical authorization.

SIL 2 native design: The MPC4MK2 and RLC16Mm2 relay modules have been designed from the outset to meet the IEC 61508 SIL 2 safety integrity level, suitable for critical applications requiring safety instrumented systems without the need for lengthy "in use validation" cycles.

3. Enhanced relay and configuration experience

Relay improvement: The MPC4MK2 has increased the number of built-in relays to 5 (including 1 module fault alarm), and the RLC16MK2 relay is sealed with epoxy resin, providing normally open/normally closed contacts and supporting software configuration of "normal excitation/normal loss of excitation" mode.

Intuitive configuration software: The new VibroSight TECT configuration environment adopts graphical drag and drop operations, reducing rack configuration time by more than 50%, and supporting rich functional configurations for single channel and dual channel (such as radial vibration) processing.

4. Unified software environment: VibroSight

Integrated platform: VibroSight integrates protection configuration, status monitoring, data visualization, diagnostic analysis (such as Bode plot, polar coordinate plot, spectrum plot), and third-party system interfaces into a unified suite, ending the relatively dispersed state of the first generation software.

Wide hardware support: This software can not only manage old and new VM600 racks, but also access third-party protection system data through XMV16 modules, and support distributed monitoring hardware VibroSmart.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor