WAGO 281-611 Fuse Terminal Analysis

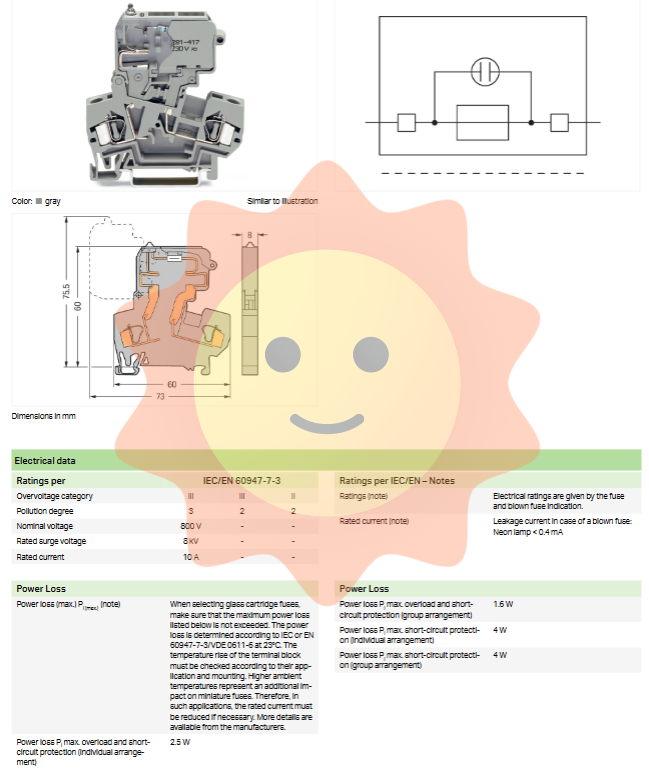

WAGO AGO 281-611 series 2-pole fuse terminal block

The WAGO 281-611/281-418 series is a high-performance 2-pole fuse terminal designed specifically for industrial control cabinets and distribution systems. This product integrates fault indication function and innovative wiring technology, providing reliable overcurrent protection for circuits with voltages up to 800V. The following is a detailed parameter analysis based on official technical documentation.

1. Core electrical parameters

The WAGO 281-611 series is designed specifically for high-voltage environments and has excellent electrical performance indicators:

Rated voltage: 800 V AC/DC, capable of meeting the needs of most industrial power systems.

Rated current: 10A, suitable for high current load protection.

Rated surge voltage: 8 kV, in compliance with Class III overvoltage category standards, ensuring safety under power grid surges.

Fuse type: Supports 5 x 20 mm miniature metric fuses.

Fault indication: Built in neon light that lights up when the fuse is blown. The leakage current of the indication circuit is less than 0.4 mA, which ensures visibility and meets low power consumption requirements.

Compliant with standards: Following IEC/EN 60947-7-3/VDE 0611-6 standards.

2. Wiring technology and conductor compatibility

This terminal adopts WAGO's famous CAGE CLAMP ® Spring pressure connection technology is the core advantage of its stable electrical performance:

Maintenance free and earthquake resistant: No need to tighten screws, strong resistance to vibration and thermal cycling, ensuring long-term contact stability.

Conductor type support:

Copper conductor: supports multiple strands of fine twisted wire and single strand hard wire, with a cross-sectional range of 0.08... 4 mm ² (28... 12 AWG).

Aluminum conductor: This is a major highlight of the product. By using WAGO "Alu Plus" conductive paste (item number 249-130) in combination, this terminal can reliably connect single stranded aluminum wires with a cross-sectional area not exceeding 4 mm ² (12 AWG). Conductive paste can effectively destroy the oxide layer, prevent new oxidation, and prevent electrochemical corrosion between aluminum and copper.

Stripping length: The required stripping length is 9... 10 mm (approximately 0.35... 0.39 inches).

3. Mechanical structure and installation design

The mechanical design of WAGO 281-611 fully considers the practicality of industrial sites:

Installation method: Installed using 35 mm DIN rails (35 x 15 and 35 x 7.5).

Appearance design: Angled design, conducive to wiring.

Shell material: Polyamide (PA66), meets UL 94 V-0 flame retardant rating, and has excellent fire resistance (combustion heat value 0.324 MJ).

Size: With a width of only 8mm, it greatly saves space inside the control cabinet (height 60mm, depth 60mm).

Fuse operation: Designed with a rotatable fuse holder. When replacing the fuse, there is no need to open the cover plate. Simply move the fuse holder to the locked open position, which is easy to operate and safe.

4. Power loss and thermal management

In high current applications, the thermal performance of terminals is crucial:

Maximum power consumption:

Single group independent arrangement: maximum power consumption is 4 W.

Group arrangement (with overload and short circuit protection): maximum power consumption is 1.6 W.

Environmental requirements:

Storage temperature: -35 ° C to+85 ° C.

Continuous operating temperature: -60 ° C to+105 ° C.

Attention: When used in high temperature environments, the rated current should be appropriately reduced according to the derating curve of the fuse manufacturer.

5. Security authentication and application

WAGO 281-611 has obtained multiple international authoritative certifications, ensuring its safe use worldwide

European Union (EU): Complies with EN 60947-7-3 standard.

North America: Obtained UL certification (code E45172) and CSA certification (code 1505034).

Marine: Obtained ABS (20-HG1941090-PDA) and DNV GL (TAE00001V2) certifications.

Functional safety: It has an IP20 protection level (center mark) and the fuse holder can be securely locked in the disconnected position (anti touch finger) when vertically assembled.

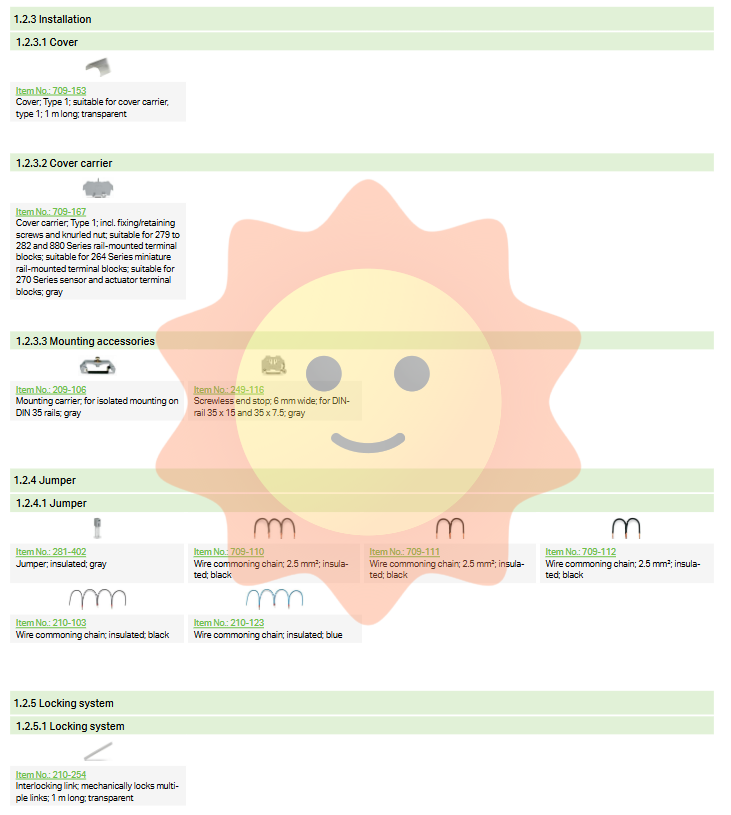

6. Attachments and Extended Functions

In order to meet diverse labeling and wiring needs, WAGO offers a rich accessory system:

Marking system: Supports multiple colors of WMB marking cards (such as blue, gray, red, etc.), supports manual printing or intelligent printer printing, and facilitates circuit recognition.

Crossover: Provides jumper wires of different lengths and colors for bridging current.

End plate: Provide end plates and intermediate partitions to block unused terminal space.

summary

The WAGO 281-611 2-pole fuse terminal block is an ideal choice for fuse connections in modern industrial distribution cabinets due to its 800V high voltage resistance, integrated neon fault indication, excellent compatibility with aluminum wires, and compact DIN rail design. Its CAGE CLAMP technology and "Alu Plus" wiring solution provide users with a maintenance free and safe electrical connection experience.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor