YOKOGAWA PW701 is a high-performance power module developed by Yokogawa Electric specifically for the Centum CS/VP and ProSafe RS key industrial control systems. It is the power core equipment that ensures the stable operation of the core control system. This product focuses on the high reliability power supply needs of industrial grade, adopts precise voltage regulation technology and redundant configuration design, and can stably output 5.1V DC standard voltage, providing continuous and reliable power support for field control stations (FCS), various I/O modules, and communication units. It is an ideal power supply solution for mission critical automation and safety application scenarios.

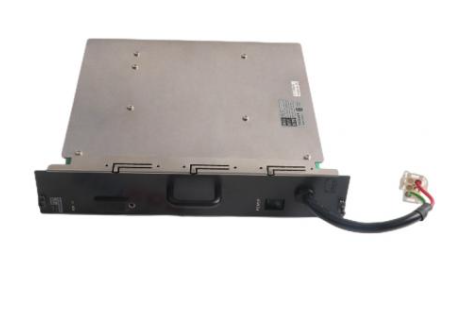

YOKOGAWA PW701 power module

Product Overview

YOKOGAWA PW701 is a high-performance power module developed by Yokogawa Electric specifically for the Centum CS/VP and ProSafe RS key industrial control systems. It is the power core equipment that ensures the stable operation of the core control system. This product focuses on the high reliability power supply needs of industrial grade, adopts precise voltage regulation technology and redundant configuration design, and can stably output 5.1V DC standard voltage, providing continuous and reliable power support for field control stations (FCS), various I/O modules, and communication units. It is an ideal power supply solution for mission critical automation and safety application scenarios.

Relying on Yokogawa Electric's profound technical accumulation in the field of industrial control, the PW701 power module adopts industrial grade high-quality components and rigorous engineering design, with excellent operational stability and environmental adaptability. Its compact rack mounted design can be seamlessly integrated into the standard control cabinets of Centum CS/VP and ProSafe RS systems, while supporting redundant pairing deployment, greatly improving the fault tolerance of system power supply. The product strictly follows international industrial safety standards and has passed multiple authoritative certifications to ensure compliant and stable operation in complex and demanding industrial environments such as petrochemicals, electricity, metallurgy, etc.

Core technical parameters

The technical parameters of the YOKOGAWA PW701 power module have been specially optimized for key industrial control systems, fully covering high reliability power supply requirements. The specific parameters are as follows:

1. Core parameters of power supply

-Input voltage range: 100-120V AC, supporting 50/60Hz AC input, compatible with mainstream industrial power grid standards, with stable voltage adaptation capability.

-Rated output voltage:+5.1V DC, precise voltage regulation design, providing standard and stable power supply for the core control components of Centum CS/VP and ProSafe RS systems.

-Rated output current: 29 amperes, with sufficient power reserve, a single module can meet the simultaneous power supply needs of multiple I/O modules and control units, ensuring full load operation of the system.

-Output power: 147.9W (calculated from 5.1V DC x 29A), with excellent power density, capable of efficiently supporting the power requirements of critical control systems.

-Heat dissipation method: Natural convection heat dissipation, no need for additional cooling fans, reduces the risk of mechanical failure, and reduces operating noise, suitable for enclosed industrial control cabinet environments.

2. Environmental adaptation parameters

-Working temperature range: -20 ℃ to+50 ℃, with wide temperature working ability, can adapt to different temperature environments such as industrial workshops and control rooms, ensuring power supply stability under extreme conditions.

-Storage temperature range: -40 ℃ to+85 ℃, in line with industrial storage standards, convenient for transportation and long-term storage in harsh environments, avoiding the impact of temperature and humidity changes on equipment performance.

-Relative humidity: 0% -80% RH (no condensation), able to adapt to low to medium humidity industrial environments, effectively preventing internal circuit short circuits or component aging caused by humidity.

-Anti interference performance: It has strong electromagnetic interference (EMI) and electromagnetic compatibility (EMC), meets industrial grade anti-interference standards, can resist electromagnetic interference generated by industrial field frequency converters, motors and other equipment, and ensure power supply stability.

3. Electrical safety parameters

-Insulation resistance: The insulation resistance between the input and output ports of the power supply is ≥ 100M Ω (500V DC) to ensure electrical safety and avoid the risk of leakage.

-Voltage endurance performance: The power input port and output port can withstand a voltage endurance test of 1500V AC for 1 minute, and the input port and ground terminal can withstand a voltage endurance test of 1000V AC for 1 minute, meeting industrial electrical safety standards.

-Protection function parameters: The overvoltage protection threshold is approximately 5.6V DC ± 0.2V DC, the overcurrent protection adopts a constant current limiting mode, the short-circuit protection response time is ≤ 10ms, and the fault circuit is quickly cut off.

-RoHS compliance: Due to industrial exemption clauses, it does not fully comply with RoHS standards. Please refer to the product manual and local regulatory requirements for specific compliance.

4. Physical parameters

-Dimensions: 254mm x 76mm x 279mm (length x width x height, i.e. 10.0 ″ x 3.0 ″ x 11.0 ″), compact rack design, compatible with standard mounting racks for Centum CS/VP and ProSafe RS systems.

-Installation method: Rack mounted (exclusive FCS or ProSafe RS system rack), firmly installed and easy to integrate with the system, can be synchronously laid out with other control modules.

-Weight: Approximately 2.0kg, structurally stable, easy to handle and install on site, suitable for the load-bearing requirements of industrial control cabinets.

Core functions and advantages

1. Redundant configuration and high reliability power supply guarantee

The core advantage of PW701 power module is its support for redundant pairing deployment, providing multiple power supply reliability guarantees for critical industrial control systems:

-Redundant deployment capability: It can be paired with modules of the same model to achieve N+1 redundant power supply. When the main power supply module fails, the backup module can seamlessly switch to work, ensuring uninterrupted power supply and guaranteeing the continuous operation of Centum CS/VP and ProSafe RS systems, reducing downtime losses.

-High MTBF design: The mean time between failures (MTTF) exceeds 100000 hours. Calculated based on an average daily operation of 24 hours in industrial scenarios, the theoretical MTTF can reach more than 11 years, significantly reducing equipment maintenance frequency and operation costs.

-Precise voltage regulation and ripple control: Adopting advanced voltage regulation circuit design, the output voltage has high accuracy and low ripple coefficient (≤ 50mVp-p), effectively avoiding the impact of voltage fluctuations on precision control components and ensuring system control accuracy.

2. Comprehensive security protection function

-Multiple electrical protection: Built in triple core protection circuits for overvoltage, overcurrent, and short circuit. When faults such as abnormal power supply voltage, output overload, or short circuit occur, the protection mechanism can be quickly activated to cut off the faulty circuit and protect the module itself and connected core control equipment from damage.

-Surge protection: With certain surge protection capabilities, it can withstand external voltage shocks such as power grid surges and lightning induction, ensuring the safe operation of the module in complex power grid environments.

-Safe grounding design: equipped with dedicated protective grounding terminals, strictly following grounding standards can effectively prevent leakage risks, ensure the personal safety of operation and maintenance personnel, and enhance the module's ability to resist electromagnetic interference.

3. System adaptation and integration advantages

-Exclusive System Adaptation: Designed specifically for Yokogawa Centum CS/VP distributed control system and ProSafe RS safety instrumented system, it can achieve seamless integration without the need for additional adaptation components, simplifying the system construction process.

-Rack mounted integrated design: Adopting standardized dimensions that match the system rack, it can be directly installed in the FCS control station rack and co arranged with other control modules and I/O modules to improve the space utilization of the control cabinet and facilitate overall system maintenance.

-Simple wiring design: equipped with clear input and output wiring terminals, accompanied by detailed wiring identification, making it easy for on-site engineers to quickly complete wiring operations, reduce installation errors, and improve construction efficiency.

4. Convenient status monitoring and operation management

-Visual status indicator: equipped with power running lights, fault alarm lights and other status indicator lights, it can intuitively display the power supply status, running status and fault information of the module, making it easy for on-site operation and maintenance personnel to quickly judge the equipment operation status.

-Integrated diagnostic function: supports linkage with the system's upper computer monitoring software, can upload module operating parameters (such as output voltage, output current, module temperature) and fault information in real time, achieve remote status monitoring and fault warning, and provide data support for predictive maintenance.

-Security protection design: The ProSafe RS system adaptation model has an anti unauthorized access function, which can effectively prevent illegal operations and ensure the safety of system power supply.

Installation and usage specifications

1. Installation precautions

-Installation environment: It should be installed in a dry, ventilated, non corrosive gas, and non strong electromagnetic interference location; Avoid installation near direct sunlight, high-temperature heat sources (such as heat dissipation devices, steam pipelines), or areas susceptible to rainwater erosion; The installation environment must meet the requirements of working temperature and humidity, ensuring smooth natural convection and heat dissipation.

-Installation spacing: When installed side by side with other modules or devices, at least 30mm of heat dissipation spacing should be reserved to ensure natural convection heat dissipation and avoid affecting operational stability due to high temperature accumulation; When deploying redundancy, it is recommended that the distance between two modules be no less than 20mm for easy wiring and maintenance.

-Installation and fixation: Strictly follow the installation specifications of Centum CS/VP and ProSafe RS system racks to ensure a secure installation and avoid module loosening or poor contact caused by equipment vibration; During the installation process, avoid collisions and squeezing of equipment to prevent damage to the casing or internal circuits.

-Professional installation requirements: Installation operations must be completed by professional engineers or skilled technicians, strictly following local installation specifications and electrical safety standards, and referring to the official product manual of Yokogawa Electric to avoid safety hazards or equipment failures caused by non professional operations.

2. Wiring specifications

-Cable selection: The power input cable should be a copper core cable recommended by Yokogawa Electric, with a current carrying capacity that matches the rated input current of the module (recommended to be ≥ 4mm ²); Select low impedance cables for output to reduce voltage loss and ensure power supply stability; The insulation level of the cable must be ≥ AC 600V and comply with industrial electrical safety standards.

-Shielding and grounding: It is recommended to use shielded cables for power cables, with a single end grounding of the shielding layer and a grounding resistance of ≤ 4 Ω to effectively suppress electromagnetic interference; It is necessary to strictly connect the protective grounding terminal to ensure reliable grounding, and it is strictly prohibited to cut off or disconnect the grounding line.

-Wiring inspection: Before wiring, it is necessary to confirm that the input voltage matches the rated input voltage of the module; Pay attention to the positive and negative polarity when wiring to avoid module damage caused by reverse connection; After all wiring is completed, it is necessary to check the firmness and correctness of the wiring again to ensure that there are no looseness, short circuits, or other issues.

-Redundant cabling: During redundant deployment, the input cables of two modules should be connected to different power supply circuits, and the output cables should be connected to the load through a redundant distributor to ensure that a single power supply circuit failure does not affect the redundancy switching effect.

3. Usage and maintenance standards

-Power on inspection: Before starting up, it is necessary to check the cable connection, grounding condition, and installation fixing status. After confirming that there are no errors, the power can be turned on; After the first startup, check the module's operating status and output voltage through the status indicator light and upper computer software to ensure they are normal. When deploying redundancy, test the reliability of the switching function.

-Daily maintenance: Regularly clean the dust and debris on the surface of the equipment and inside the rack to maintain smooth heat dissipation; Regularly check the cable connections to avoid looseness, aging, or damage; Regularly monitor module operating parameters through monitoring software, promptly detect anomalies and handle them; Suggest establishing a maintenance ledger to record operational data and maintenance status.

-Fault handling: When a module encounters a fault alarm, the fault code or monitoring platform's fault information should be checked first to preliminarily determine the type of fault (such as overvoltage, overcurrent, module fault); When troubleshooting, the input power must be cut off first, and it is strictly prohibited to disassemble equipment with power on; Maintenance requires the use of spare parts certified by Yokogawa Electric, and unauthorized modification of the internal circuits of the equipment is strictly prohibited; After troubleshooting, a trial run test is required to confirm that there are no issues before it can be put into normal use.

-Storage and handling: When the equipment is stored for a long time, it should be placed in its original packaging, and the storage environment should meet the requirements of storage temperature and humidity, avoiding mixing with corrosive substances, flammable and explosive materials; Avoid severe impact and vibration during transportation to prevent equipment damage; After being stored for more than 6 months, insulation resistance testing and performance testing should be conducted before use.

-Taboo scenario: This product is not designed for critical applications that directly affect or threaten human life (such as core power supply of nuclear power safety systems). If it needs to be used in such scenarios, users need to configure redundant equipment and protective mechanisms to ensure personnel safety, and obtain relevant authoritative certification.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-