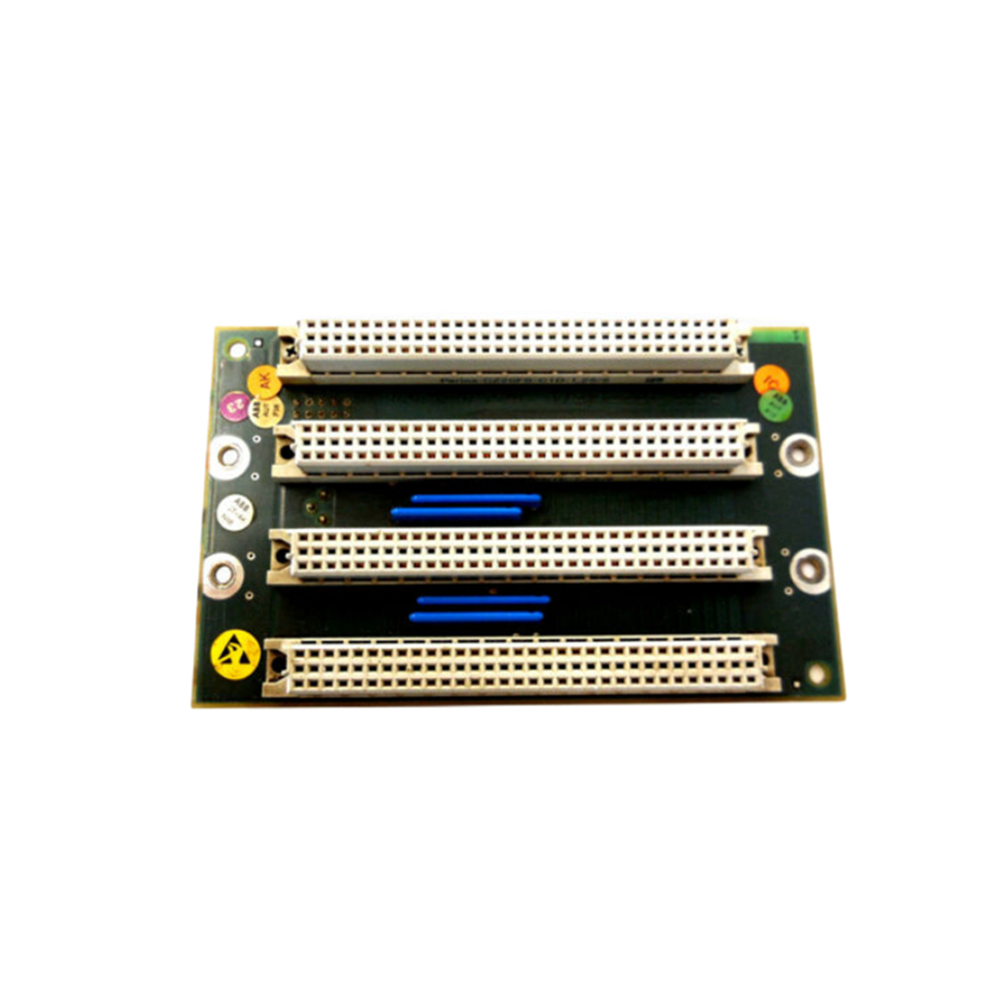

ABB DSBB175: High-performance communication processing module for industrial automation

Powerful data processing and storage: large capacity memory and efficient data processing algorithms enable DSBB175 to quickly process and store large amounts of industrial data. It can not only process communication data in real time, but also store and analyse historical communication data, which provides powerful data support for the optimization of industrial production processes and fault diagnosis.

Note

Power Connection: When connecting the 24V DC power supply, make sure that the power supply voltage is stable and the polarity is correct. It is recommended to use a high-quality power adapter with overload protection and filtering to avoid damage to the module caused by power fluctuations and surges, and to ensure that the power supply is well grounded to improve power safety.

Communication wiring: When wiring the communication interface, it is necessary to operate in strict accordance with the wiring diagram to ensure that the wiring is firm and correct. Use standard communication cables, and according to different communication protocols and transmission distances to choose the right type of cable, such as shielded twisted-pair cable, etc., and at the same time do a good job of cable grounding to reduce the impact of electromagnetic interference on the communication signal.

Environmental requirements: Although DSBB175 has a high level of protection and a wide range of operating temperatures, but still should try to avoid placing it in the installation of strong electromagnetic interference near the source, such as large motors, frequency converters and other equipment. If it can not be avoided, effective electromagnetic shielding measures should be taken, such as the use of shielded cabinets, electromagnetic shielding devices, etc., to ensure the stability of the module communication.

Software Configuration and Update: Before using the module, the communication protocol, IP address, port number and other parameters should be correctly configured according to the actual industrial application requirements. During the configuration process, the parameter settings should be carefully checked to avoid communication abnormalities caused by parameter errors. At the same time, pay regular attention to the official software update information released by ABB, and upgrade the module's firmware and drivers in a timely manner in order to obtain better performance and new functions, and enhance the compatibility and stability of the module.

Comparable Models

ABB DSBB180: Compared with DSBB175, DSBB180 may have further improvement in communication processing performance, such as supporting more kinds of communication protocols, or having greater breakthroughs in data transmission rate and processing capacity, which can meet more complex and demanding industrial automation communication scenarios. In terms of the type and number of interfaces, DSBB180 may be increased to adapt to the connection needs of more devices and improve the scalability of the system.

ABB DSBB170: As a simplified version of the DSBB175, the DSBB170 is relatively weak in terms of functionality and performance. It may support a smaller variety of communication protocols, and its data processing power and memory capacity are also relatively small. However, its advantage lies in its lower cost, which makes it suitable for small industrial automation projects that do not require particularly complex communication functions, limited budgets, or simple industrial scenarios that do not require high communication performance .

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor